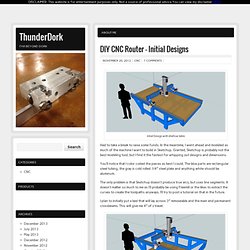

Tweakie, Tweakie.CNC, CNC, router, mill, engraver, vinyl cutter, laser. Solsylva CNC Plans~ Home Page. DIY CNC Router – Initial Designs. Intial Design with shallow table Had to take a break to raise some funds.

In the meantime, I went ahead and modeled as much of the machine I want to build in Sketchup. Granted, Sketchup is probably not the best modeling tool, but I find it the fastest for whipping out designs and dimensions. You’ll notice that I color coded the pieces as best I could. The blue parts are rectangular steel tubing, the gray is cold rolled 1/4″ steel plate and anything white should be aluminum. The only problem is that Sketchup doesn’t produce true arcs, but uses line segments. I plan to initially put a bed that will lay acroos 3″ removeable and the main end permanent crossbeams.

Intial design deep bed With the lowered to the next junction I should have access to the full 22″ of z travel. Initial design with bed removed And if that isn’t enough or if i build an underhung 5 axis milling head, I can remove the bed completely if need be. DIY CNC Router. If you have any interest in purchasing a kit version of this machine please click the above button and complete the form so that I can gauge the level of interest.

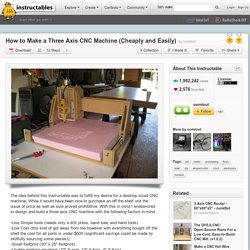

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc. I wanted to join this revolution of digital fabrication and start making my projects even better using these tools. DIY CNC. Third machine was Jabott and this was just a fun little project using up bits and pieces I had accumulated.

Fourth Machine was Rodot and I took a lot of time modifying my design to improve the machine. Note the cranked gantry. Here is a hybrid X2 mill I did. CNC Machine Building - Design. Components.

DIY CNC CO2 Laser Site. DiY. Homemade Router Laser CNC. In this page I will show you how I have build a Router Laser CNC using some part from old printers, a Epson Stylus 800 and another Epson Stylus Color II, (you can use your old printer).

Aplications: Cutting Paper. To make stencils for painting with airbrush.Wood and Cardboard Engraving. Write and paint in wood whitout ink.Plastic Engraving. To write in plastic without special inks.Plastic Cutting. We can start obtaining the X axis from the old printer. We will not use the other parts, as control board, we need change it by another CNC control board with stepper drivers. Homemade DIY CNC Machine using Step Motors, Dremel, and EMC2. Tags: CNC, DIY, Machine, Motor Control, Robot, Robotics, Stepper Motor What is a CNC?

The abbreviation CNC stands for computer numerical control, and refers specifically to a computer “controller” that reads G-code instructions and drives a machine tool, a powered mechanical device typically used to fabricate components by the selective removal of material. In simple words, a CNC is a machine which is controlled by a computer, and used to fabricate 3D objects. This page will describe the process of building a CNC machine, from the design stage, the required materials and the process itself. Still confused? After seeing the movie, you must have understood how useful that kind of machine is for printing electronic circuit boards or manufacturing robot parts. My diy cnc milling plasma laser 3d printer machine - SolidWorks, STEP / IGES, STL.

CNC. Homebuilt CNC Router #1: A Journey - by SPalm. After posting my Woodworker’s CNC Router in the projects section, I received several requests to show how I made it.

I debated whether to post something here or just send them off via a bunch of links. I decided to show you the journey that I took over several years and ended up with the machine that was posted. So here goes. Do you need one? 25x25~Solsylva CNC Plans. Construction These plans are for builders who have a minimum of tools and only modest shop experience.

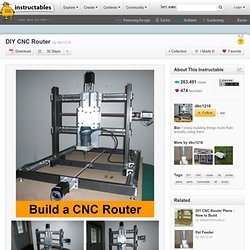

The plans include detailed step by step directions with dimensioned drawings of all parts. Aaron Bowser’s CNC Machine. Thinking about building a CNC machine?

Hacked Gadgets forum member, Aaron Bowser has a site loaded with information on how to build one. Not only is there helpful information about his design, there is also a vast number of links to other resources. “The mechanical design of the machine was based on a survey of CNC machine websites and on the availability of used and surplus parts.

A y-axis gantry style, similar to the one used by Axxus Technologies, was selected. The stepper driver board currently used in this project was created based on the application notes from the UN5804B stepper driver from Allegro Microsystems. You Can Build A Homemade DIY CNC Machine. Homemade DIY CNC - From Start To Finish - Motor Mount Part 2 - Neo7CNC.com. Learcnc items - Get great deals on reprap, 3d printer items on eBay Stores! How to Make a Three Axis CNC Machine (Cheaply and Easily) A salute to those who have laboured through to this point (and to demonstrate that it is reproducable) Here are some pictures of other peoples machines.

Photo 1 - Chris and his friend put together this unit; laser cutting the parts out of half inch acrylic. Not only does it look super it must weigh a ton. But kudos, anyone who's worked with acrylic knows laser cutting it is great but it is a very very unfriendly material to drill and there is a lot of side drilling in this design. Good job guys, check out more details (and photos including some testing with circuit boards) on Chris's blog rainbowlazer.com. I particularly like his work with making 3-d objects out of 2d cuts (here) . Homemade 2'x4' Wood CNC Router. DIYLILCNC. RouterStrap 3D printer on the CNC Machine. Build Your Own CNC Router, CNC Machine, or 3D Printer. 3D Printing. Modular Desktop CNC Machine by AJ Quick.

What is CNC? A CNC is essentially a machine that is controlled by a computer and can perform highly intricate maneuvers over and over again (similar to a printer). In this case instead of dispensing ink onto the paper, it uses a cutting tool to cut very detailed shapes into common materials like wood, plastic, & aluminum. It is a critical machine in any manufacturing factory, or research and development lab.

We think it’s a tool that will be found in every workshop and home garage in the future. DIY CNC Router Plans : How to Build. NOTE: I originally posted this on my arts and crafts blog, Make It With Jason, and you're welcome to go visit and check out my other tutorials, reviews, and step by step drawing and painting lessons. The DIYLILCNC: Open-Source Plans For a Low-Cost, Easy-to-Build CNC Mill. (v1.0.2) Homemade CNC Fraiseuse à commande numérique Mach 3. SmartCaster: Open source automatic roto-casting machine by Aurelio Reis. A rotocaster has a few advantages as well as a few disadvantages to a 3D printer, meaning it does work very well as a compliment as opposed to replacement.

Materials wise you have a big advantage as you can use a casting material with different texture, strength or flexibility whereas with 3D printers it's usually some sort of rigid plastic. Casting materials tend to be a little on the expensive side unless you buy in bulk so I would say it's about a draw there with the 3D printer maybe being a little cheaper. While the option does not exist with rotocasting some of the more expensive 3D printers allow you to print with different colored plastics to make non-solid colored objects but this is not common. Finished (roto)casts are high quality and usually don't need much post processing to be usable whereas most (affordable) 3D printers do require some degree of finishing since they tend to create objects with strange surface properties.

Black Rynius' Blog. CNC Machine Front view. Machine Type Joe’s Model 2006 R2 Work Area Controller Rockcliff 4-axis Controller case outside. Rockcliff controller with power supply inside a stripped out fuse panel box. Software Artsoft Mach3 Motors. CNC. DIY Desktop CNC Machine by Stephen. A modular, inexpensive, versatile desktop-scale CNC machine to put computer-automated machining and fabrication in the hands of creators. Whether they be hobbyists or evil scientists, small-scale manufacturers or budding inventors, the power to go from on-screen design to precision-machined product in a few mouse clicks is very exciting. See this project Updates section for pictures and video of the working prototype.

This project will result in a finished, new, well-designed CNC machine that will then be made available in kit form at several different project entry points. From well-documented and comprehensive plans and construction manual, through electronics, motor drive and chassis kit combinations, to fully-assembeled systems, there should be a solution to fit any skill-level and/or budget. The machine is intended to be built by the average DIY-er, either from scratch from plans, or from a full or partial kit. I've developed, prototyped and tested the electronics. Questions? Desktop CNC Mill Kit - Shapeoko 2. Product Details IMPORTANT NOTE REGARDING SHIPPING: Mechanical Kits have a 1 week lead time, Full Kits have an estimated lead time of 4-5 weeks. CNC Machinist Cookbook: Software and Information. MadVac CNC - home made 4'x8' cnc precision gantry router.

The design objectives for MadVac CNC: General purpose 4 axis (two Z axis) production machine capable of 2D and 3D routing of material within 7" x 52" x 99" envelope Milling wood, plywood, plastics, all grades of aluminum and softer metals 3D mold making Repeatability and precision of movement to 0.0005" and better Heavy, relatively rigid structure Easily accessible open table Small footprint base Modular design for disassembly, moving and reassembly Repeatable and accurate assembly Upgradeable to servo motors Compact Y gantry with Z and W axis both of which can work in 52" x 99" envelope Mobile controller console that can move to any point around the machine Complete mechanical, electronics, software system under $16,000.