Messer Cutting

Our product range includes oxyfuel, plasma and laser cutting systems, from hand-guided machines right up to special machines for shipbuilding, as well as plant and equipment for oxyfuel welding, cutting, brazing and heating. Spare parts, repairs and modernisation services round off the program as well as environmental equipment for the systems.

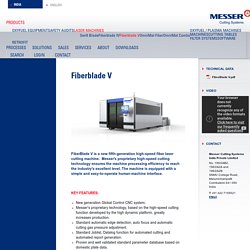

Fiberblade V - Fiber Laser Cutting - Messer Cutting. FiberBlade V is a new fifth-generation high-speed fiber laser cutting machine.

Messer's proprietary high-speed cutting technology ensures the machine processing efficiency to reach the industry's excellent level. The machine is equipped with a simple and easy-to-operate human-machine interface. Key Features: New generation Global Control CNC system. Messer's proprietary technology, based on the high-speed cutting function developed by the high dynamic platform, greatly increases production.

Messer Laser Cutting Machine & Laser Cutting Services. CNC (Computer Numerical Controller)is computer-controlled cutting machine mostly referred to hand-held machine used for cutting the metals.

Laser cutting machine uses high powered lasers to cut through ferrous metals and some non-ferrous metals like aluminium & brass. The laser beam is produced in a closed glass resonator using a mix of helium-co2-co-n2 as exciting medium. The laser beam is instructed by bend mirrors placed along the bellow path. High pressure assist gas is used to blow away the material cut. Fume Extraction Systems. With our powerful fume extraction systems and channel units we assist our clients with contributing to ensuring protection of the earth.

We focus on the best answer for you actually and monetarily. Messer Fume Extraction system in any assembling industry exhaust and tidies delivered at various machines and diverse sources/areas. In specific cases giving separate fume extractors to each smoke producing sources may not be an efficient choice. In such cases a concentrated residue the extractors with appropriately planned conduits and hoods will be a more efficient and successful alternative. Messer empowers you to get dust extraction and fume extraction right. We offer actually pushed fume extraction system that are widely used to ensure men working in the collecting plants from dangerous vapor and gasses.

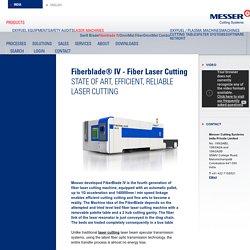

This Fume Extraction System is broadly utilized for isolating particulate issue from dust loaded air more. Fiber Laser Machine, Fiber Laser Cutting - Fiberblade IV. Messer developed FiberBlade IV is the fourth generation of fiber laser cutting machine, equipped with an automatic pallet, up to 1G acceleration and 140000mm / min speed linkage enables efficient cutting cutting and fine arts to become a reality.

The Machine idea of the FiberBlade depends on the attempted and tried level bed fiber laser cutting machine with a removable palette table and a 2 hub cutting gantry. The fiber link of the laser resonator is just conveyed in the drag chain. The beds are traded completely consequently in a bus table Unlike traditional laser cutting laser beam specular transmission systems, using the latest fiber optic transmission technology, the entire transfer process is almost no energy loss.

Key Features: Plasma Cutting Machine, Plasma Cutting Services & Systems. Plasma cutting was originally developed for the thermal cutting of materials which were unsuitable for flame cutting, such as high alloy steels or Aluminum.

Today, the process is also used for the economical cutting of thin, low alloyed steels. What is Plasma? The Fourth State of Matter One common description of plasma is to describe it as the fourth state of matter. We normally think of the three states of matter as solid, liquid and gas. Messer CNC Laser Cutting Machine & Laser Cutting Services. CNC (Computer Numerical Controller)is computer-controlled cutting machine mostly referred to hand-held machine used for cutting the metals.

CNC laser cutting machine uses high powered lasers to cut through ferrous metals and some non-ferrous metals like aluminium & brass. The laser beam is produced in a closed glass resonator using a mix of helium-co2-co-n2 as exciting medium. Profile cutting machine , CNC profile Cutting System - Terrablade-d. Newly Developed state of art, affordable CNC profile Cutting system.

TerraBlade a popular CNC Profile cutting machine, is idealy suited forsmall and medium prodution companies to take control of their prodution by doing their own steelprofile cutting in house. Equipped with simple, easily operatable gas console supplemented with MS 932 torch & its quickchange nozzles ensure high quality gas cutting. Ideally suited for Variety of plasma system increase the scope of applications. Extrely stable & reliable German technology at indian price. . We are occupied with offering TerraBlade-D Messer’s best profile cutting machines, which are accessible in different sizes and details to provide the requests of customers. Key Features: MetalMaster 2.0 - Economical Plasma & Oxyfuel Cutting Machine. Are you looking for an economical machine which gives full power in a small area?

For simple plasma cuts, just oxyfuel or also both combined? With the new MetalMaster 2.0 you will get Messer quality at a unique value for money Price. Thanks to the space saving, compact construction the machine can be installed quickly ready for use. Levelling screws make child’s play of alignment on a flat surface. Bilateral longitudinal drives with precision guiding system maintains accuracy over long periods of use. The user-friendly touch-screen control Global Control 2.0 means you need only 3 klicks from loading the part program to being ready to cut. Key Features: Oxy fuel Cutting - Process Explained. Oxy-fuel cutting are forms that utilization fuel gases and oxygen to cut metals separately.

Oxy fuel fire cutting is the most temperate process for the cutting of mellow and low combination steel, even with weld arrangements. It is a standout amongst the most critical creation forms in the metal business. Oxy fuel cutting is a burning procedure utilizing oxygen/fuel gas fire. The warming fire conveys the material up to its start temperature. At that point a fly of oxygen no less than 99.5% unadulterated is blown onto the warmed spot. All low amalgam steel with a material thickness up to a few inches can be cut with this procedure.

Oxy fuel cutting guarantees solid opening penetrating, high cut quality which the creation of parts to their completed sizes without the requirement for additionally handling. Laser Cutting Systems, Company, Machine, CNC, Service. Basically when cutting with the laser the beam is focused on the material through the hole in the nozzle.

This heats the material and melts it. A cutting gas, which as a rule flows co-axially through the nozzle, removes the molten material. Fiber Laser Cutting Machine Explained. Assembling of Fiber Laser Cutting Machine or Fiber Laser Machine, our company had overseen by the young, skilled, experienced and enthusiastic accomplices those who have constantly given improvement to give the best of the Laser Cutting Products and CNC mechanization arrangements in the business. Quickly, fiber laser light is made by banks of diodes. The light is diverted and increased through fiber optic link like that utilized for information exchange. The opened up light, on leaving the fiber link, is collimated or fixed and afterward centered by a focal point onto the material to be cut. A fiber laser is where the dynamic medium being utilized is an optical fiber that has been doped in uncommon components; commonly, erbium, ytterbium, neodymium, thulium, praseodymium, holmium or dysprosium.

The fiber laser will stay effective by utilizing close to 100% the info that it gets, yet it likewise implies that less of this power is being changed over into warm vitality. Fume Extraction Systems. With our powerful fume extraction systems and channel units we assist our clients with contributing to ensuring protection of the earth. We focus on the best answer for you actually and monetarily. Messer Fume Extraction system in any assembling industry exhaust and tidies delivered at various machines and diverse sources/areas. In specific cases giving separate fume extractors to each smoke producing sources may not be an efficient choice. In such cases a concentrated residue the extractors with appropriately planned conduits and hoods will be a more efficient and successful alternative.

Messer empowers you to get dust extraction and fume extraction right. We offer actually pushed fume extraction system that are widely used to ensure men working in the collecting plants from dangerous vapor and gasses. Oxy fuel Cutting Process Explained. Oxy-fuel cutting are forms that utilization fuel gases and oxygen to cut metals separately. Oxy fuel fire cutting is the most temperate process for the cutting of mellow and low combination steel, even with weld arrangements. It is a standout amongst the most critical creation forms in the metal business. Oxy fuel cutting is a burning procedure utilizing oxygen/fuel gas fire. The warming fire conveys the material up to its start temperature. At that point a fly of oxygen no less than 99.5% unadulterated is blown onto the warmed spot.

All low amalgam steel with a material thickness up to a few inches can be cut with this procedure. Oxy fuel cutting guarantees solid opening penetrating, high cut quality which the creation of parts to their completed sizes without the requirement for additionally handling. CNC Cutting Machines, CNC Laser Cutting and CNC Plasma Cutting. When you see how a CNC cutting machine functions, you'll see that they can be used with machines and devices of different sorts. CNC Cutting machines or Computer Numerical Control machines make utilization of PC frameworks and programming projects to robotize hardware, including very perplexing and propelled tasks. In that capacity, a CNC cutting machine (additionally called a consume table) makes utilization of CNC procedures to cut materials of different sorts including steel, aluminum and wood.

Plasma Bevel Cutting, Bevel Cutting Plasma. Bevel cutting requires an exact knowledge of the machine and the cutting processes. Corners, lead-ins and run-outs have to be cut with special sequence if the required quality is to be achieved. Bevel cutting also places high demands on the programming of the cut parts. Special auxiliary functions are needed to set the units up for bevel cutting. Two key components are required for a best quality completed slanted part: exactness and precision.

Fiber laser cutting technology. Messer Cutting Machines. Metal cutting machine is a sort of laser cutting hardware for metal materials, for example, Hot Rolled Steel, Cold Rolled Steel, Aluminum, Stainless Steel, Alloy Steel, Brass, Bronze, Copper, Galvanized Steel, and Tool Steel. Laser Cutting Systems, Company, Machine, CNC, Service. Cutting table, Plasma, Oxyfuel, Laser, Thermal, Messer Cutting table. Fiber Laser Machine, Fiber Laser Cutting - Fiberblade IV. Profile cutting machine , CNC profile Cutting System - Terrablade-d.

Metal cutting machine -Straight Cutting Oxyfuel for all cutting tasks. Thermal Cutting Process with CNC Cutting Technology. The most reasonable thermal cutting strategy for you relies on upon the kind of material, material thickness, the required cutting quality and dimensional resistances. Machines-Plasma,CNC,Oxyfuel,Thermal,Profile,Metal & Laser Cutting. CNC Cutting Machine Services & Systems.