R.O.V. Technologies Inc. - PWR BMH Inspection. R.O.V. offers several standard Inspection Systems that perform a variety of tasks.

All of R.O.V.'s Inspection Systems have been designed with time savings and radiological dose savings in mind. R.O.V. can customize inspection systems based on customer requirements. The Scarab IIIP was designed to address an industry need to remotely inspect Pressurized Water Reactor (PWR) heads for evidence of boron deposits due to weld degradation. This inspection criterion became evident due to the discovery of a failed inconel alloy 600 nozzle weld joint discovered at a U.S. operating station, and the high susceptibility to primary water stress corrosion cracking (PWSCC). PARROT BEBOP DRONE (AQUA) - drone mecca. Subsea illustrasjon / ROV illustrasjon. R.O.V. Technologies Inc. - Cleaning. R.O.V. offers a complete line of standard and customized equipment including cameras, camera systems, crawlers, submersibles, manipulators, all related accessories, and work tools.

All equipment manufactured by R.O.V. is manufactured specifically for the nuclear power industry; it is not modified equipment from other environments. CMU's snake robot explores defunct nuclear power plant / 2045 Initiative. Founded by Russian entrepreneur Dmitry Itskov in February 2011 with the participation of leading Russian specialists in the field of neural interfaces, robotics, artificial organs and systems.

The main goals of the 2045 Initiative: the creation and realization of a new strategy for the development of humanity which meets global civilization challenges; the creation of optimale conditions promoting the spiritual enlightenment of humanity; and the realization of a new futuristic reality based on 5 principles: high spirituality, high culture, high ethics, high science and high technologies. The main science mega-project of the 2045 Initiative aims to create technologies enabling the transfer of a individual’s personality to a more advanced non-biological carrier, and extending life, including to the point of immortality.

We devote particular attention to enabling the fullest possible dialogue between the world’s major spiritual traditions, science and society. Espy 360 ROV – Underwater Spy Monitors Marine Environment In More Effective and Safer Way. Egyptian Students Design an Underwater Remotely Operated Vehicle - ArabCrunch… Arab Tech Arab Startups. Most of the stories that we and other who publish news about Arab tech and startups tend to focus on web startups, but what about inventions in other teach sectors namely hardware?

From now on we will be posting stories about Arab hardware inventions and startups. Today we present a story about Egyptian students designing an ROV Underwater Remotely Operated Vehicle as a graduation project for the year 2013. The students are from Alexandria University from Marine engineering and ship building division. Black News and Entertainment Los Angeles. “Live every week like it’s Shark Week.”

Underwater ROV. Underwater Robot Competition Proved a ‘Rollercoaster Ride’ for Duke Robotics Club. The 10th annual International Autonomous Underwater Vehicle competition held in San Diego, Calif., from July 11-15 proved a "rollercoaster ride" for student members of the Duke Robotics Club.

Navy looks to Bluefin for enhanced UUV technology to inspect hulls of ships at anchor - AUVAC. February 26, 2013 - via Military and Aerospace Electronics ARLINGTON, Va., 26 Feb. 2013.

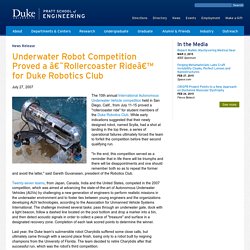

U.S. Celebrating Robotic Technology and Roving Bats. HydroView Sport Remote Operated Underwater Vehicle. HydroView Pro 5M Remote Operated Underwater Vehicle. Ultimate mini remote operated underwater vehicle (ROV)Underwater control with six degree freedom of motionFive motors, three sensors and 2 pounds of payload capabilityReal time video and high definition recordingDepth: 330 ft. (100 m) cable dependent The HydroView Pro 5M Remote Operated Underwater Vehicle is the ultimate mini ROV on the market.

The 5M model has five motors, three sensors and 2 pounds of payload capability, HydroView Pro has been engineered for versatility across various underwater applications. The unique motor configuration gives the operator complete control over movements forward/backward, up/down, as well as roll, pitch and yaw. The HydroView Pro, a mini remote operated vehicle (ROV), includes LED lights, HD camera, depth sensor, temperature sensor, orientation sensor, standard 250 foot cable, waterproof carrying case, Topside box which generates its own Wi-Fi, propeller guards, free download of the application to use on your iPad, PC or MAC computer. Magnetic Mobile Robotic Inspection System.

Versatrax 100 MicroMag™ The MicroMag™ mobile robotic inspection vehicle is compact, waterproof and magnetic.

It can be rapidly deployed for many applications that exclude most ordinary ROV's. The MicroMag™ visual inspection system has been engineered to deliver vivid color video footage in real-time while travelling almost any direction on ferrous metal surfaces. This unique remotely operated device is steerable on vertical, horizontal and inverted plains even when piloted underwater. The standard MicroMag™ crawler is equipped with a flat aluminum chassis, a powerful rare earth magnet component, a pair of rugged aluminum Microtracs™ and an industrial Spectrum 45™ pan / tilt camera that boasts six high intensity LED lights. As with all Inuktun remote visual tools, MicroMag™ Operators will appreciate the portable controller, intuitive software interface and familiar joy-sticks. For more information, please phone or email your nearest location: History (?) News Releases : March 10, 2014 : Hitachi Global. Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.

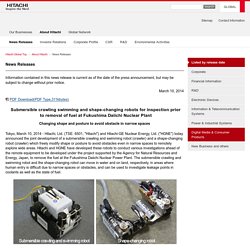

Changing shape and posture to avoid obstacle in narrow spaces Tokyo, March 10, 2014 - Hitachi, Ltd. (TSE: 6501, "Hitachi") and Hitachi-GE Nuclear Energy, Ltd. ("HGNE") today announced the joint development of a submersible crawling and swimming robot (crawler) and a shape-changing robot (crawler) which freely modify shape or posture to avoid obstacles even in narrow spaces to remotely explore wide areas.

Hitachi and HGNE have developed these robots to conduct various investigations ahead of the remote equipment to be developed under the project supported by the Agency for Natural Resources and Energy, Japan, to remove the fuel at the Fukushima Daiichi Nuclear Power Plant. Details of the mobile equipment developed are as below. RISYS: An Advanced Reactor Vessel Inspection System with Underwater Mobile Robots. Abstract: An underwater mobile robotic system for ultrasonic examination of reactor vessel welds has been developed to reduce inspection time and schedule during mandatory code inspections.

Instead of a conventional inspection machine with a large structure, the underwater mobile robot with a long reach manipulator examines the whole welds of the reactor vessel. The system mainly consists of an underwater mobile robot, a laser positioning unit and a main control station. EJAM(5-1-NT54) Robot Technologies of PWR for Nuclear Power Plant Maintenance. In the maintenance work of the nuclear power plants and facilities, there are many locations where the works by field workers are difficult or impossible, due to the conditions such as small space or narrow gap, under-water, high radiation dose rate, etc. To solve these problems, many robots are applied for the maintenance work as a means to perform the works in place of the workers (Fig. 1).

MHI has developed the typical maintenance and inspection robots in order to realize the wide variety of required work contents. 1. RV Inspection Robot 2. ROV for NPP - HU. Intercontrole: specialist in non-destructive power plant examinations. Nuclear power plant services (safety, security, maintenance): nuclear energy offer INTERCONTROLE-Activités. Innovative Robotics and Ultrasonic Technology at the Examination of Reactor Pressure Vessels in BWR and PWR Nuclear Power Stations.

NDT.net - October 1998, Vol.3 No.10 Introduction Inservice inspections on the reactor pressure vessels of nuclear power plants not only demand high standards of technology and quality but increasingly require that more emphasis be placed on economics. The aim is to cut down on the time required for inspections thereby shortening nuclear power plant outages and to cut the cost of performing such inspections.