Mary Paul

Factoryworx provides Industry 4.0 and Artificial Intelligence enabled solutions and services to the manufacturing industry.

Paperless Manufacturing and Document Management System. Automated Transportation and Warehouse Management System. FactoryWorx Transportation FactoryWorx Transportation As the entire industry is becoming technology driven, manufacturing companies are appreciating the involvement of automation in transportation to enhance their logistic operations.

Automated Factoryworx transportation improves scheduling, routing, reliability of the entire logistic ecosystem. Real-Time Factory Maintenance Management System: FactoryWorx. Inventory Tracking and Warehouse Management System. FactoryWorx Project and Predictive Asset Management Solutions. Predictive Maintenance in Manufacturing. Real-time Job Shop Scheduler and Supply Chain Integration. Manufacturing Industry Roadmap: Guiding Project Execution. Project Roadmap Project RoadMap The project roadmap is a simple graphical, distinguished summary of the project’s goals and deliverables presented on a timeline.

It is a handy tool for handling investor anticipations and targets as well as for interacting policies , strategies, and communicating assets with different teams. Manufacturing Dashboard: Factory Production Monitoring Dashboard. Manufacturing Dashboard: Factory Production Monitoring Dashboard. How Production Monitoring System Creates Smart Manufacturing Environment? Most of the manufacturers are busy with their daily shop floor productivity.

Based on this productivity, they align their budgets. As manufacturers give high priority to the shop floor, it is critical to have real-time monitoring solutions. Successful manufacturers, who find faster growth of their businesses, deal with business intelligence and analytics, by relying on real-time data. In the world of industry 4.0 or smart manufacturing, the importance of real-time production monitoring cannot be overstated. Thus, to find a better outcome and higher revenue from your manufacturing business, you can use a reliable production monitoring system.

Minimize soft and hard fault errors– It is something related to Mean Time To Repair and Mean Time Between Failure. Gain useful feedback on the process and product simulations. How Does Maintenance Management System Help In Smart Manufacturing? With the increasing complexities and growth of your manufacturing businesses, you may have found it challenging to stay abreast of industry trends.

Most of the manufacturers have started looking for faster and smarter ways of operating businesses. The toughest thing for manufacturers is to conduct maintenance tasks. With traditional pen-and-paper approaches, they cannot achieve their goals. Thus, for smart manufacturing solutions, a Computerized Maintenance Management Systems has become the best choice. CMMS systems have made it easy to- Track work ordersCheck inventory statusGenerate reports with a high accuracyIdentify business assets that need preventive maintenance Limitations of traditional maintenance-management approaches Before developing CMMS systems, manufacturers hire maintenance technicians to deal with work orders and essential manufacturing parts. No option for real-time updates– Spreadsheets do not automatically address your maintenance requirements.

Optimize your inventory– The Advantages of Paperless Manufacturing Software for Smart Factory. We live in a digital world, where software is rapidly replacing manual work.

Everything has sped up, so it makes sense to adopt a paperless system. Long gone are the days when the scent of crisp white paper was the highlight of an office job. Today, leaders in every industry have abandoned the conventional approach to working hard and embraced the concept of working smart. Cloud Based Energy Management System Service Provider. Webinar Journey to Industry 4.0 - From Operational Excellence to Smart Manufacturing. Operational Excellence Guest Webinar – 7 July 2020 Register to attend FactoryWorx’s Guest Webinar on “Getting Started with Industry 4.0“, to be held on Tuesday 7th July at 11am AEST.

This webinar will be presented by FactoryWorx. The session will cover: Manufacturing Resource Planning. Manufacturing Resource Planning (MRP) Manufacturing Resource Planning Manufacturing resource planning (MRP) is a method for the effective planning of all resources of a manufacturing company.

FactoryWorx MRP assists manufacturers in dealing with production planning, scheduling and inventory control, etc. to bring out the best yield possible from the manufacturing process. Benefits of FactoryWorx Manufacturing Resource Planning: 1. Availability of resources is the main driving force of any manufacturing process.FactoryWorx MRP provides status of cost and availability of these raw materials.Having the update of the materials, gives an idea to the manufacturer to properly engage the available raw materials in the production line. 2. The FactoryWorx MRP system analyses the raw materials to be used in the production phase and estimates the exact amount and cost of inventory for completing the production schedule.It does inventory cross cutting and time optimization in the production phase. How Artificial Intelligence is Revolutionizing the Manufacturing Business?

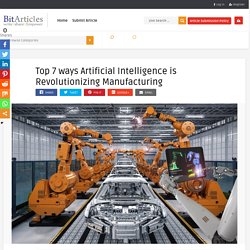

How Artificial Intelligence impacts in Manufacturing Business? Artificial Intelligence (AI) has the potential to enrich and outspread the competences of individuals, and assist companies accomplish further, sooner and more competently.

For a huge cluster of industries including all government and privately owned, such as, banking, retail,healthcare, etc, AI is widely used and is gradually approaching in the manufacturing sector too, enabling industrial Automation. AI-driven technologies are positioning an easier track to the upcoming years by giving out a cluster of benefits such as creating new opportunities, improving productivity , and fetching machine interface closer to human interaction. Industry 4.0 is carried out by automation, thereby re-engineering man and machine connection and communication. Factory Dashboard: User Friendly, Responsive with Location Based Insights. Industry 4.0 Solutions the Future of Manufacturing Industry. Industry 4.0 Production Management, Reporting, Monitoring System. FactoryWorx Production Reporting Management Get a Demo Production Reporting System and its Management Over the past few years, Internet of things has aimed each consumer in almost every industry.

This has been empowering businesses to embrace industry 4.0. for providing smarter services with smart factories. Cloud based Management Software: FactoryWorx.