Laney Shaughnessy. Make a Table Saw Out Feed Table Part 3. Sources (Note: Product availability and costs are subject to change since original publication date.)

Small Shop Storage Solutions. Small Shop Storage Solutions Photos by Chris Wong Lead Photo by Ted Robinson Last year during a seminar lunch break, I returned to the shop and heard one student say to another, “Yeah, it’s really nice – you have to go see it one day.”

I cut in, “What are we talking about?” 15 Free Mobile Base Plans: Put Your Power Tools on Wheels. So I was lurking the other day over at Woodnet and stumbled on a video that shows a smart, easy to build and cheap mobile power tool base.

That got my wheels turning and I started up my research engine. When the dust settled I had 15 mobile base plans for you! Here’s the thread that inspired this post: Shop Built Mobile Base (with video) The biggest problem doesn’t seem like it’s mobility, but rather STOPPING a mobile tool from rolling so you can use it safely. There’s an astounding range of solutions for this below – it’s interesting how many variations there are on such a seemingly simple problem. MDF versus particleboard. Strength and other qualities in relation to cabinet construction.

How to Prevent Blotching Using a Washcoat - Wood End Grain Raised Panel Door Furniture Stain Staining Dyes Dying. Furniture Finishing & Restoration.

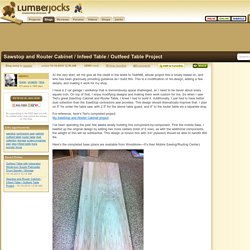

My SawStop and Router Cabinet with Fold-down Outfeed Table and Dust Arm - by tedth66. Since I use my garage as a shop and have limited space, I had the desire to combine my router table and SawStop into one cabinet and create some storage in the process.

I started with a purchased plan but only used the support base in the plan and drastically changed the cabinet portion of the plan to add a lot of storage. There are three drawers under the saw with one false drawer front on the dust cabin. The center tall cabinet in the middle is a storage shelf for blades and tablesaw accessories. Sawstop and Router Cabinet / Infeed Table / Outfeed Table Project - by zzzzdoc. At the very start, let me give all the credit in the world to Tedth66, whose project this is totally based on, and who has been graciously providing guidance as I build this.

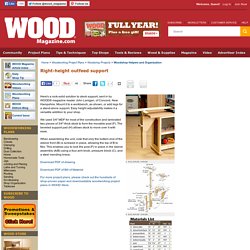

This is a modification of his design, adding a few details, and making it work for my shop. Countertop with custom wooden edges. HOW TO INSTALL BEVEL EDGE ON A LAMINATE COUNTERTOP. Wilsonart Decorative Edges Installation. Here's a rock-solid solution to stock support, sent in by WOOD® magazine reader John Lanigan, of Concord, New Hampshire.

Mount it to a workbench, as shown, or add legs for a stand-alone support. Easy height adjustability makes it a versatile addition to your shop. We used 3/4" MDF for most of the construction and laminated two pieces of 3/4"-thick stock to form the movable post (F). The beveled support pad (H) allows stock to move over it with ease. When assembling the unit, note that only the bottom end of the sleeve front (B) is screwed in place, allowing the top of B to flex. Download PDF of drawing Download PDF of Bill of Material For more project plans, please check out the hundreds of shop-proven paper and downloadable woodworking project plans in WOOD Store.

Store your expensive carbide-tipped blades between protective layers.

This handy divider lets you organize and protect your favorite saw blades. We dimensioned ours to fit into a drawer in our shop. If you like this project, please check out more than 1,000 shop-proven paper and downloadable woodworking project plans in the WOOD Store. WOOD Store. Built-in window seat instalation photos.

Plywood takes up relatively little space and is easy to store—simply lean it against a wall. The trick is getting at it when you need it. Nine times out of 10, you need the half sheet that’s buried behind 12 others. If you’ve experienced that frustration, you’ll love this rack. Casters and a set of hinges are the secret for easy access.

They allow you to swing the storage rack out from the wall and slide out the storm window, paneling or other item you want. Each slot has room for about six sheets of 3/4-in. plywood. Construction of the rack goes surprisingly fast. Bolt Depot - Fastener Information - Terminology, Measurement, Materials and more. Screws are Screws – Aren’t They? Just as with building any woodworking project, eliminate one step from the manufacturing process and the results can be fatal. Twisting, bending and breaking are just three of many results you sometimes experience when working with screws. Choose better – not necessarily more expensive – screws to reduce those occurrences.

It usually happens as you hang a door or install a shelf. You’ve got a balancing act going as you hold one piece, steady a second piece and attempt to drive a screw all at the same time. AutoSpeed - All You Need to Know About Nuts & Bolts. Button head, grade 5, pan head, 8 x 1.25 – what’s it all mean? If you’re buying nuts and bolts, this is all vital information. Identifying Fasteners If you don’t know how to describe what you want, chances are that you won’t be able to get it! Threaded fasteners are identified by these attributes: type, material, diameter, length, and thread pitch or count.

Type Fasteners are divided into categories based on their function or design eg wood screw, sheet metal screw, hex bolt, lag bolt, etc. Head Style Many categories are also available with different head shapes or styles. eg flat head, pan head, truss head, etc. Material Fastener material describes the material from which the fastener was made as well as any material grade eg stainless steel, zinc plated steel, silicon bronze, etc. Diameter.