We have in-house CAD design division has a dynamic and vivacious team of engineers, draftsmen and 3D modelers who have quite good experience in high-end tools lie AutoCAD, SolidWorks, DriveWorks, and many more. How Engineering Design & Drafting Company helps Product Manufacturers? Increasing number of product manufacturers tried designing and developing products in-house, in the bid to save costs and reduce the time to market.

But most of them failed miserably. Sheet Metal Fabricators Should Change Their Imperative Tool. If a metal fabrication shop doesn’t change and resists adoption of new technologies; it will soon get obsolete.

The same goes for sheet metal fabricators, if they do not change their tools at right time, they too will become redundant. By doing so, fabricators will only be obstructing innovation that drives technically robust and ergonomically efficient designs. It will be equally true even for the fabricators who are CAD driven. Is the right cutting tool sufficient for quality sheet metal fabrication? Popularly used sheet metals [viz. steel] will have a gauge size that varies between 9 and 13 and thickness from 0.17 inches to 0.12 inches. However, the matter here isn’t about cutting. SolidWorks Sheet Metal Fabrication Design. Design for Manufacturability (DFM) for Product Design Saves Time and Money. The Design for Manufacturability (DFM) is a widely adopted process of designing a part or product that meets the requirements of manufacturing processes to actually produce the part.

It is the responsibility of product engineers to not only design the part for fit and function, but also design it to remain feasible for manufacturing. Avoiding DFM in product development can significantly influence the cost and delay the product launch. This is primarily due to the fact that almost 80% of the budget, including material cost, tooling cost and assembly cost are already worked out once the product moves from conceptual phase to design phase. It becomes very much difficult then to re-design the part/product, if issues crop up at later stages of the development cycle.

The cost then keeps on increasing exponentially in efforts that are put up to make the design manufacturing friendly. DFM is a proven process to save time and cost in the product development cycle. About Author : Reverse Engineering is not just 3D Scanning and CAD Modeling. The manufacturing industry has been long established with sophisticated machinery setups even before the times of CAD, and they have been operational to deliver optimum results.

But simultaneously, factory/plant owners and design engineers have made changes, replacements, realignments and upgradation to parts owing to continuous operational wear and tear. Now, as these machines were built pre-CAD era, their designs were never digitized and neither were the changes. The original fabrication drawings, assembly drawings and part models also made on typical engineering drawing sheets have also degraded. And it is almost impossible to have every maintenance and realignment documented when designs are on paper, especially when the equipment is operated by multiple operators, engineers, and OEMs. The big challenge of productivity But the issue of challenges does not stop here; it goes beyond.

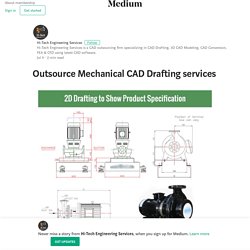

Evaluating the concurrency of reverse engineering. High-Quality CAD Conversion Services Firm. High-Quality Mechanical CAD Drafting & 2D / 3D CAD Drawing Services Firm. Detailed engineering being one of the most crucial tasks of the product development, it encompasses a whole set of information which if misrepresented, leads to cascading adverse effects across fabrication process.

If you are a design engineer or a manufacturing firm, you have ever experienced this. And you know it’s not only about adversities, but the time on consumed and materials wasted wrong fabrication. Evolving shop fitting industry practices with CAD and design automation. Design and planning the shop layout is at the essence of shopfitting industry as retail shops have major challenge of catering a premium look and economical usage of space.

Consequently, shopfitting furniture designer, manufacturer, and the shopfitter have an important role to play. It is in their onus to make the shop designs scream the intended use, whether it is fashion and apparels, hotels, offices, cafes or grocery stores etc. In the past, shopfitting industry was confined to a standard type of rack and shelving system, counters and basic furniture to store the merchandise. It didn’t have a significant part of the business and the shop owners too considered it as a secondary requirement. 2D CAD vs MBD: Challenges in Reading Many-facets of Design Interpretation. Sheet Metal Product Design & Drafting for Sheet Metal Fabricators. Top-notch Mechanical CAD Drafting & CAD Conversion for the Solid Product Manufacturer.

Outsource Mechanical CAD Drafting services. Hi-Tech Engineering Services is one the most trusted CAD drafting company in India when it comes to mechanical drafting, 2D/3D drafting, AutoCAD drawings.

We specialize in mechanical CAD drafting and provide technical drawings, fabrication drawings, engineering drawings, isometric drawings, assembly drawings, as-built drawings, mark-up detailing, manufacturing drawings from the given plans, blueprints, sketches and print papers. Our mechanical drafting services are offered to Engineers, Manufacturing Companies, Fabricators and Mechanical/Industrial Firms. It has a team of skilled CAD drafters who have worked on many big and complex projects. How PDF to CAD Conversion services helps Engineering & Design Firms. 3D CAD Modeling Services to Multi Disciplinary Engineering Fields. Hi-Tech Engineering Services provides innovative 3D CAD Modeling and SolidWorks Modeling and Mechanical 3D Modeling services to multi-disciplinary engineering fields.

As an India based specialized 3D modeling company; we can render and develop 3D models using SolidWorks, Solid Edge, AutoCAD and Inventor. We create 3D models from the given drawings, images, sketches, etc. We also provide our 3D CAD modeling service to manufacturers, contractors, fabricators and engineers. How to Evaluate Best Mechanical Product Design Company? About The Mechanical CAD Drafting Procedure. Mechanical CAD drafting is a procedure which imparts the engineers, design developers and the fabricators with the capability to visualize the mechanical projects in three dimensional aspects.

With the advancement in the computer-aided tools and techniques, the drawings are not only limited to paper drawings. The drawings developed by the mechanical CAD drafting process are not only detailed and accurate but can also be designed in a faster way, thereby saving a significant amount of time. The professionals known as the drafters may have to design different types of mechanical components such as jigs, fixtures, clamps, conveyor belts and much more simple and complex designs.

Developing sketches of the mechanical components is one of the fundamental duties of the drafters. Sketches are also known as free hand drawings and a drafter can generate different idea options of the designs. What is Casework in Woodworking: Overview. Casework is standard and mass-produced furniture, with boxed-shaped pieces.

It is usually made in standard dimensions. The fundamental idea is to manufacture pre-fabricated building products, which are possible to assemble on-site, at least partially. Any ready-to-purchase boxed furniture including bookcases, cabinets, cases, shelving, storage furnishing, and mostly woodworking products falls under the category casework. Sometimes, casework is partly an assembled cabinetry. What is Keeping Manufacturers from Shifting to 3D CAD? Despite more than a decade since the introduction of 3D CAD modeling in the manufacturing industry, right from giant manufacturing companies to small scale fabricators there are engineers and machine operators who still use 2D drawings. To them, looking beyond the challenges in migrating to 3D is difficult. CAD Drafting for Fabricators: Your Complete Guide. CAD drafting holds utmost importance from design drafting and development to all the way through the manufacturing.

CAD Designing and Drafting Services for Mechanical Product Design. CAD was introduced with an aim to eliminate the painstaking drafting on sheets and eliminate the errors in accurate geometric dimensioning, of crucial industrial parts and machinery components, for manufacturing. How CAD helps engineers? Industrial design engineers saw a great relief in communicating their design intent, with help of CAD designing and drafting, to their fabrication contractors or the manufacturing firms.

Well-designed, neat 2D CAD draft is much better than a handmade 2D drawing prepared on drawing sheet with rulers and a French curve. Furthermore, a 3D CAD model developed on the basis of CAD drawings, help in communicating every design feature to the manufacturing firm engineers and the foremen operating the machines. Mechanical product designing in CAD can be done with optimized size, shapes, topology and geometric features of the component alongside its functionality.

What are the Advantages of 2D Over 3D CAD Drafting? The main advantage of 2D CAD drafting over 3D is that 3D CAD usually found and saved in digital format and having access to computers with data connectivity is not possible in remote manufacturing, fabrication or construction sites. Hence, it’s profitable for engineers, architects and manufactures to use 2D CAD drawings, for they can be generated in a printed format that can be carried anywhere – including remote worksites.

Apart from these, there are several other advantages of 2D CAD drafting over 3D. A few of them are listed below; 2D drawings run on any PC: The need for 2D drawings rather than 3D would arise where there’s unavailability for a higher performance machine and the project must go on without any break in its cycle. A pause of a few hours might create a great loss for the manufacturing business and no manufacturer would want to incur such losses. What are the Factors to Consider When Choosing a Right Sheet Metal Product Design Company? Choosing is the right sheet metal company who can deliver quality work is a challenging decision. There are many companies who offer sheet metal product design services, but Hitech Engineering Services is one of the best companies I have come up with. It's an ISO Certified Engineering design company who works with complying all the applicable industry standards and regulations by validating mechanical designs, optimizing design performance.

Why the shift to CAD Models for Products Having Readily Available Design Is Recommended? Innovative Concepts with Product Design and Development. Why Should You Outsource Your CAD Design Services to India? Customizing Sheet Metal Product Necessarily Loses Customers; Think Again. Contractors appreciate you as a sheet metal manufacturer and have always been loyal to you whenever a new order arrives. Your customers too are satisfied with the kind quality of fabrication your shop floor rolls-out and the designs your engineers are developing. But customers are tired of good products and even the best designs are not being sold. Such issues of increased display life happen frequently in case of architectural ornamental products such as canopies, handrails, roofs or balustrades. Customers want their products to be good in quality but do not want what others can have. Customers need their customized designs and yet want to maintain the quality.

You as a manufacturer will have to ask your building products design engineer to stock every option to manufacture or you will have to convince the retailer to buy only what you have manufactured, leaving a significant number of customers dissatisfied. Let the customers tell you what they want Normal Case versus Configured Case. 3D Furniture Design and Rendering: Effective Advertising Solution for Manufacturers. Furniture manufacturers globally, struggle with one common challenge – finding the right way to advertise their products. Which CAD Platform is Best for Wooden Furniture Design? Millwork Drafting Services: Importance of Offshore Service Provider.

Interiors and architectural plans of the building are only so good if they have complementary set of furniture placed at strategic locations. Best in 2D CAD Drafting and Detailing Services. Hitech Engineering Services has been in the CAD industry with more than 20 years of experience. What Are Some of The Best Firms Providing Mechanical Product Design Services Globally? 6 ways CAD Drawings can Transform your Millwork Manufacturing.

What are the Best Woodworking Software Programs? Furniture manufacturer industry has seen impeccable variations in the usage of woodworking software like Sketchup, Homestyler by Autodesk, Smart draw Cabinet design, Opun Planner and the list is endless. What is the Best Way to Design Metal & Steel Doors and Frames Using CAD? It all depends on what type of doors you are referring to. What CAD Software is Best for Designing and Modeling Furniture? What is One Advantage of 2D Over 3D CAD Drafting? What are the main benefits offered by 3D SolidWorks modeling? No matter how complex and huge your designs and assemblies are; well-experienced SolidWorks engineers and consultants can create all the detailed designs with highest photo-realistic view according to requirements such as the wireframe models, mesh models, surface models and solid models.

The comprehensive SolidWorks tools that we use for, Conic surfacing tool: With the help of the Conics Sketcher tool, we create hybrid models in a much faster way. Moreover, we coordinate the existing geometries while fostering smooth transitions between them. Varying dimension patterning: This particular tool gives us the flexibility to select the feature dimensions for variations easily. Why Should Outsource Sheet Metal Drawings & Design Services?

Converting PDF to CAD for Manufacturing Design Needs? CAD Configurator for Custom Doors to Achieve Right Design Mix. CAD Drafting Services: Dependence of Retail Furniture Manufacturing Industry.