High Demand for Industrial Gases 2021 -Oxygen and Nitrogen - Oxygen Plants. After nearly complete industrial disruption because of COVID-19, the situation is improving fast in the year 2021.

There were lockdowns in every part of the world with the global pandemic playing havoc. Only the industries manufacturing essential commodities were allowed to continue their operation the rest were shut down. Obviously, it caused economic distress to the manufacturing sector. Moreover, this sector is heavily dependent on the use of industrial gases mainly oxygen and nitrogen.

How Industrial Oxygen is Generated/Manufactured? - Oxygen Plants. Oxygen is a vital gas because of its extensive application in so many industries.

It aids in combustion although in itself it is combustible. It is the most important property which finds extensive applications in wide cross-section of industries. Earth’s atmosphere contains 21% oxygen which is not adequate for industrial applications. For obtaining higher concentration of oxygen we have to use industrial processes.

Installing Liquid Oxygen Filling Plant for Medical & Hospital - Oxygen Plant. Liquid oxygen (LOX) is a pale blue liquid which is produced by liquefaction of atmospheric air in a liquid oxygen filling plant using cryogenic distillation process.

It has boiling point of 297.3°F (-183°C). Oxygen is abundantly found in the planet Earth’s atmosphere. UBP Series Oxygen nitrogen plant 50 to 170 m3 per hour. Medical Oxygen Plant for Hospital and Nursing Homes. Medical oxygen gas plants are used for generating onsite oxygen for use in hospital.

Medical oxygen has purity up to 99.7% and is used for giving resuscitation and inhalation therapy. It is also used for treating COPD, cyanosis, shock, severe hemorrhage, carbon monoxide poisoning, trauma, cardiovascular and respiratory arrest, and resuscitation. Cryogenic Liquid Oxygen Plant for Sale - Oxygen Plant. We are one of the leading manufacturers of oxygen plants, which are constructed using the best quality materials and components.

Industrial gas business is very lucrative but it is capital-intensive. In order to lower the burden on the pockets of our customers, we have started to offer cryogenic liquid oxygen generator for sale. As we have kept the prices quite low, this has resulted in more customers going for our oxygen machinery. An oxygen plant is used for generating on-site oxygen for industrial and medical applications. Industries now find it profitable to install onsite plants for guaranteeing regular oxygen supply.

Automatic Liquid Nitrogen Plant Machinery for Sale. Liquid nitrogen (LIN) is a cryogenic liquid found at extreme low temperatures.

It is a colorless & odorless liquid with a boiling point of (−195.79 °C). LIN is generated by cryogenic distillation of liquid air. It has numerous applications, industrial and medical, which we will discuss below. Why Prefer to Cryogenic Distillation for Oxygen Nitrogen Plant - Oxygen Plant. Oxygen is one of the most commonly found elements in the atmosphere of the planet earth.

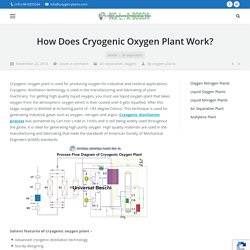

It is used for life-sustaining and industrial applications. The element constitutes around 21% of the planet earth’s atmosphere. Medical Oxygen Gas Cylinder Filling Plant Cost. How Does Cryogenic Oxygen Plant Work? - Oxygen Plant. Cryogenic oxygen plant is used for producing oxygen for industrial and medical applications.

Cryogenic distillation technology is used in the manufacturing and fabricating of plant machinery. For getting high quality liquid oxygen, you must use liquid oxygen plant that takes oxygen from the atmospheric oxygen which is then cooled until it gets liquefied. After this stage, oxygen is distilled at its boiling point of -183 degree Celsius. Acetylene Generator Manufacturers. Universal Boschi is a leading company for manufacturing and exporting technologically acetylene generators.

The acetylene generators are popular worldwide for being fully automatic and come in within the budget of everyone. In addition, it performs all the operations automatically as our company has made it in technical collaboration with ING. L. & A. Boschi of Italy. The Italian company has incorporated pneumatically controlled valves along with modern sensors and temperature controller to make it fully automatic. Automatic Cryogenic Nitrogen Plant Manufacturers in India. Cryogenic nitrogen plant sucks air from the atmosphere that comprises of gases such as nitrogen, oxygen and various others.

Nitrogen is said to constitute around 78% of earth’s atmosphere by volume. It is called as the largest industrial gas because of its application in various industrial and medical applications. After atmospheric is tapped it is moved into an air compressor where it is compressed and moved into a cleanup where impurities such as hydrocarbons, moisture and carbon dioxide are removed. Thereafter, it is run through a heat exchanger where the air is cooled to cryogenic temperatures.

Then, it is moved into a high distillation column where nitrogen is separated from oxygen and other gases and is distilled till it meets industrial and medical specifications.