Woodworking with Rob Millard. As I said in an earlier entry, I was somewhat shocked that despite careful joinery the cases were quite flimsy.

I guess I shouldn’t have been so shocked, because the sides are comparatively thin, as are the drawer blades, meaning the tenons are short and have no shoulders to speak of to resist racking. With that in mind, before any fitting of the drawers or doors could begin, the backs had to be made and installed. On some of their larger pieces, the Seymour’s used a frame and panel back, so this is what I used. The frame and panel is ideal, because it provides considerable racking strength at a minimum weight. I’m not sure what configuration the back panels took on Seymour pieces, but I chose to go with three horizontal rails; top, bottom and one at the level of the lowest drawer blade.

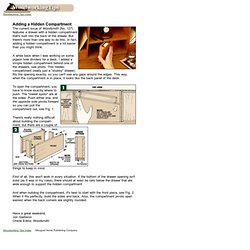

Woodsmith Tips — Tips, Techniques, and Videos from Woodsmith and ShopNotes. Adding a Hidden Compartment - Woodworking Project. Adding a Hidden Compartment The current issue of Woodsmith (No. 127) features a drawer with a hidden compartment that's built into the back of the drawer.

But there's more than one way to do this. In fact, adding a hidden compartment is a lot easier than you might think. A while back when I was working on some pigeon hole dividers for a desk, I added a simple hidden compartment behind one of the drawers, see photo. Make: Projects - Router Trammel. Repaint your kitchen cabinets without stripping or sanding, with... Disclosure: Rust-Oleum paid for my transportation, lodging and food to attend this special event in New Orleans, where I could test this new product and hear directly from their company experts.

There was no promise of news coverage. Getting screws to hold in end grain. Because wood is relatively weak perpendicular to its grain, screws don't hold that well when screwed into the end grain.

This firstly because the thread has a harder time cutting into the grain fro the side, and also because what it does grab shears out more easily, as the shear is cross-grain. Wood screws do, however, hold extremely well in cross grain. Handy Nation & Blog Archive & A Must for Dust. How To Make Mission Furniture Part (1) 1. Copyrighted, 1909, by H.H.

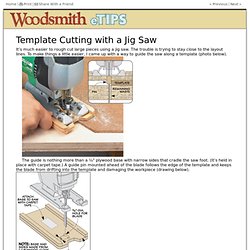

WINDSOR Suitable for Dining Room Use Details of Chair Construction A mission chair suitable for the dining room can be made from any one of the furniture woods to match the other articles of furniture. The materials can be secured from the planing mill dressed and sandpapered ready to cut the tenons and mortises. Template Cutting with a Jig Saw & Woodsmith Tips. It’s much easier to rough cut large pieces using a jig saw.

The trouble is trying to stay close to the layout lines. To make things a little easier, I came up with a way to guide the saw along a template (photo below). The guide is nothing more than a ¼" plywood base with narrow sides that cradle the saw foot. (It’s held in place with carpet tape.) Kubb Kubbspel Contruction Game Plans - How to make.

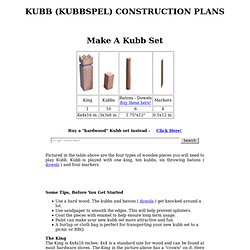

Pictured in the table above are the four types of wooden pieces you will need to play Kubb.

Kubb is played with one king, ten kubbs, six throwing batons ( dowels ) and four markers. Some Tips, Before You Get Started Use a hard wood. Box Joint Jig Plan - Take a Closer Look. Miter Joint Corner Clamp. Gluing a miter joint is a challenge .

There just isn't an easy way to clamp it. The store-bought clamps I've tried in the past didn't always pull the joint together. So I came up with a shop-built corner clamp that uses wedges to push (or press) the mitered pieces in place. Looking at the photo at the right and drawing below, you can see that this corner clamp uses a piece of plywood as a base. Then a square block and two cleats are glued and screwed on top. What's important here is that the inside corner of the square block is exactly 90°. Block Plane Basics. More and more woodworkers are bringing power jointers and planers into their shops, often pushing hand planes into dusty corners. But a plain old plane still comes in handy, even in the most up-to-the-minute shop.

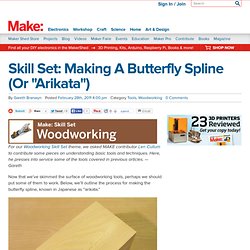

Here's one of the handiest: the block plane. (1) Compact and versatile, block planes, such as the low-angle one (left) and the standard version (right), belong in any woodworking shop. A sharp, properly adjusted hand plane allows a woodworker to peel a whisper-thin shaving from wood while leaving a surface of unsurpassed quality. Skill Set: Making A Butterfly Spline (Or “Arikata”) For our Woodworking Skill Set theme, we asked MAKE contributor Len Cullum to contribute some pieces on understanding basic tools and techniques.

Here, he presses into service some of the tools covered in previous articles. — Gareth Now that we’ve skimmed the surface of woodworking tools, perhaps we should put some of them to work. Below, we’ll outline the process for making the butterfly spline, known in Japanese as “arikata.”