TRIZ. TRIZ (/ˈtriːz/; Russian: теория решения изобретательских задач, teoriya resheniya izobretatelskikh zadatch) is "a problem-solving, analysis and forecasting tool derived from the study of patterns of invention in the global patent literature".[1] It was developed by the Soviet inventor and science fiction author Genrich Altshuller and his colleagues, beginning in 1946.

In English the name is typically rendered as "the theory of inventive problem solving",[2][3] and occasionally goes by the English acronym TIPS. Following Altshuller's insight, the theory developed on a foundation of extensive research covering hundreds of thousands of inventions across many different fields to produce a theory which defines generalisable patterns in the nature of inventive solutions and the distinguishing characteristics of the problems that these inventions have overcome. There are three primary findings of this research. §History[edit] §Basic principles of TRIZ[edit] §Essentials[edit] §Basic terms[edit] Open Source TRIZ. The Triz Journal. What is TRIZ? TRIZ Training. TRIZ Training Effective TRIZ Problem Solving in 5 days Oxford Creativity’s greatest success has been the development of a unique and effective TRIZ Training Workshop Programme which can help anyone learn TRIZ, be effective and self sufficient in TRIZ problem solving in the minimum possible time.

Oxford Creativity has developed a programme of 5 intense days, in order to fit in with the busy schedules of the engineers and managers who learn with us. These 5 days are split into 2 workshops: Basic and Advanced TRIZ. Visit the Events page for dates and venue details. Toyota Vs Nissan 567.pdf. Thesis. The secrets of success (PhD) Schwagerman-Ulmer-A3-Lean-Le.pdf. PhD Proposal Guideline. Nissan Production Way: A better alternative to TPS? I have visited three former Nissan Diesel factories in Japan this week (today owned by a foreign multinational).

The plants operate according to the Nissan Diesel Production System—a bi-product of the famous Nissan Production Way (NPW). I believe that too many lean-lovers focus too heavily on the Toyota Production System (TPS), and know too little about alternative approaches to world-class production. The core idea of an XPS is exactly that the X should be tailored to the company, and not be a TPS-blueprint. Nissan Production Way. Manufacturing execution systems and ERP integration: A happy manufacturing marriage? It used to be what happened on the plant floor stayed on the plant floor.

By submitting your email address, you agree to receive emails regarding relevant topic offers from TechTarget and its partners. You can withdraw your consent at any time. Contact TechTarget at 275 Grove Street, Newton, MA. You also agree that your personal information may be transferred and processed in the United States, and that you have read and agree to the Terms of Use and the Privacy Policy. The manufacturing execution system (MES) -- a central system for managing all manufacturing information such as resource allocation, manufacturing planning, supply chain information and quality inspection numbers -- operated as an isolated and self-contained system.

Similarly, the enterprise resource planning (ERP) system, which pulls together and stores business operating information about human resources, accounting, customer relationship management and other financials, hummed along independently. Lean Thinking & Transfer Lean338.pdf. Lean methodology. The core elements of Lean in Higher Education are two fundamental concepts, five principles and eight wastes.

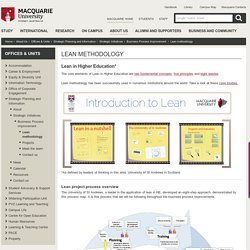

Lean methodology has been successfully used in numerous institutions around the world. Take a look at these case studies. *As defined by leaders of thinking in this area, University of St Andrews in Scotland Lean project process overview The University of St Andrews, a leader in the application of lean in HE, developed an eight-step approach, demonstrated by this process map. Two fundamental concepts Continuous improvement Continuously looking at your work processes and striving to improve them (by, for example, using the Plan-Do-Check-Act improvement cycle). Respect for peopleRemembering that our staff are our greatest asset.

Five principles. Lean and TPS.pdf. Jeff-Liker.pdf. Jeff Liker, The Toyota Way, and Unintended Consequences. I’m so grateful that we’ve queued up some excellent guests for our Lean Leadership series.

We are quite pleased to have Dr. Jeffrey Liker speak with us today. If you all turn your eyes to your bookshelves, I’m sure you will likely find a few books for which Dr. Liker has authored – when you think of lean manufacturing resources, he’s usually up there.. He has helped to bring to a general audience Lean Manufacturing and has gone on to help countless of companies adopt the Toyota Production System in their own operations. How To Write Proposal. HOW TO GET A PHD. Evaluation of the Nissan Plant Management System.pdf. Construction kata paper.pdf. AMSC2013_Hu_Jianping_DONGFENG_NISSAN_English.pdf. 6 BASIC STATISTICAL TOOLS.

There are lies, damn lies, and statistics......

(Anon.) 6.1 Introduction 6.2 Definitions 6.3 Basic Statistics 6.4 Statistical tests 6.1 Introduction In the preceding chapters basic elements for the proper execution of analytical work such as personnel, laboratory facilities, equipment, and reagents were discussed. Before embarking upon the actual analytical work, however, one more tool for the quality assurance of the work must be dealt with: the statistical operations necessary to control and verify the analytical procedures (Chapter 7) as well as the resulting data (Chapter 8). It was stated before that making mistakes in analytical work is unavoidable. A multitude of different statistical tools is available, some of them simple, some complicated, and often very specific for certain purposes.

Clearly, statistics are a tool, not an aim. 40 Inventive Principles.