Smart Shop in a One-Car Garage. Space-saving solutions for a small shop Tales of bad shops are a woodworker’s war stories.

After living in five houses in seven years, I have plenty of them to tell: ladders under closeted trapdoors that descended into windowless basements, ceilings that were only an inch taller than I am when I stand barefoot, abandoned radiators, wasp nests, snow, water—good Lord, the water—and a hole in the middle of one shop floor (about 2 ft. in diameter and 2 ft. deep) just behind the infeed side of my tablesaw . Oh, yes, I could tell you some stories. I spent a lot of time planning to condense workspaces and to make sure that machines work efficiently with one another, and I found quick and simple solutions for storage.

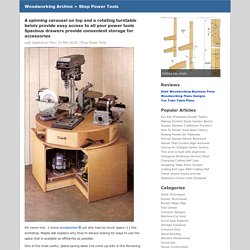

A spinning carousel on top and a rotating turntable beloiv provide easy access to all your power tools Spacious drawers provide convenient storage for accessories - Shop Power Tools. A spinning carousel on top and a rotating turntable beloiv provide easy access to all your power tools Spacious drawers provide convenient storage for accessories Vtr never met .1 home woodworker yet who had loo much space ¡11 the workshop.

Maybe dial explains why they're always looking for ways to use the space that is available as efficiently as possible. One of the most useful, space-saving ideas I've come up with is this Revolving Tool Station. Make Perfect Box Joints With a Table Saw Jig. To begin cutting a box joint, you'll need the two pieces of stock into which you'll be cutting the joint.

Typically, these two pieces of stock will be the same thickness and width, as in two corresponding sides of a drawer box. Before making the first cut, you'll need to adjust the depth of the stacked dado blade on the table saw to match the thickness of the stock being cut. For instance, if you built the jig to have 1/2" wide fingers, but the boards being cut are 3/4" thick,...MORE you'll need to raise the blade to match the thickness of the board. To make the first cut, position the board on the edge so that the end edge of the board that will be cut is flat on the table. Slide the board to the right so that it butts up against the spacer block, leaving the edge flat against the table. Turn on the table saw and push the jig all the way through the stacked dado blade. Cordless Tool Charging Station - buildsomething.com. Cordless Drill Storage - Charging Station - Her Tool Belt. Hi!

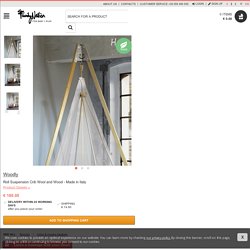

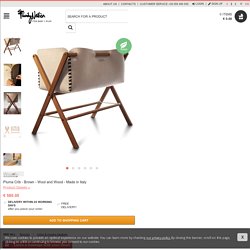

I’d love to for you to follow me on Pinterest Her Tool Belt and if you love instagram, you can keep up with me there too! Our first monthly Reader Request Plan comes from Justin! He wants a 5 dock cordless drill storage and battery charging station, that can hang on his garage wall. What a great idea to corral your drills, batteries, and battery chargers in one place. DIY Cordless Tool Charging Station (with plans) Segment Cutting Sled - by TheDane. Woodly Roll Suspension Crib Wool and Wood - Made in Italy unisex (bambini) The beautiful Roll Suspension Crib Wool and Wood by Woodly is made with solid wood (FSC certified) and stainless steel.

This strong pyramidal structure is ideal to safely support the Woodly Roll Crib. Woodly Pluma Crib - Brown - Wool and Wood - Made in Italy unisex (bambini) **This item can be shipped internationally.

Please inquire for a shipping quote.** We love the Pluma crib by the Italian brand Woodly. Turn a bought door into a fold-down worktable. Turn a bought door into a fold-down worktable.

Table Saw Sawmill Jig. Plans. Projects for children. Groomsmen Gifts - Beer Caddies. Rick's Scrollsaw. Maker Bench: an open source, CNC workbench for everyone. Sometimes, it makes sense not to rush an idea.

We’ve found that’s especially true when you need other people’s help to make it happen. Earlier this year, we had an idea, and we thought it was a pretty good one... but we weren’t sure. (That ever happen to you?) Our idea was a customizable workbench for any kind of project. We called it Maker Bench. We were pretty excited about our idea, so we shared it with other people (like you), and asked them what they thought. Then, we took a step back. We’re happy to say that many have answered our call to help design and develop Maker Bench. Just one of many clever adaptations proposed on the SketchUp forum, Jeff proposed a chop-saw accessory for Maker Bench. Then, other technologists and designers started to jump in.

Matter Machine took the open designs for Maker Bench and built them out on their own web-based parametric modeling platform. And we’ve started building Maker Benches too. That’s not to say we’re stepping away. Stick chair project page 1. Stick chair project Preface Author: Les Kenny History unknown.

How to make a seesaw with a sliding seat. Seesaw with adjustable sliding seats Introduction This seesaw has adjustable seats that are able to slide along the seesaw beam making it possible to balance a couple of riders of different weights.

The seats can be moved and locked in place at points along the beam simply with a standard pad bolt. This allows even a parent to have a balanced ride with their child. Note: You can purchase this plan in downloadable PDF file, print friendly and in clean copy (free of ads) for only $5.00. To view all available $5 downloadable plans click here. Introduction and Measurements explained. Folding picnic table made solely out of 2x4 lumber Folding picnic table in both picnic table mode and bench mode Navigation: Jump to any page of this project via the ' Table of Contents' menu on the right-hand side, or below if you are viewing on a mobile device. Scissors extending work light. This article contributed by Ron Walters Make all the slats you will need for the project plus a few extra in case of breakage or warping. The slats in this project are 15-1/2" long x 1-1/2" wide x 3/8" thick cut from a piece of 2x4. I used 5/8" dowel. Construct a simple two-pin drilling jig, which will allow you to drill all of the holes with one setup.

Cut the pins a little long. Make sure the holes in the moving slats are smooth and all slats move smoothly on the pins when assembled. A bolt and star knob is used to squeeze a C-shaped link at the end of the scissors, allowing the angle of the light to be adjusted. Threaded metal insert in the next clamp, allows for side to side swiveling and locking. Bi-Fold Hide-a-Door. Meisel Hardware Specialties. How to Build a Murphy Bed. Like many homeowners, I converted a small bedroom into a home office. It’s a trade-off that makes sense, except when we have visitors and must give up our bed. In my search for bed that wouldn't take up space I found a solution that isn’t new at all — a murphy bed. It’s an ingenious piece of furniture that combines the comfort of a standard mattress with the appearance of a closet or cabinet that is less than 18 in. deep.

You can customize most designs to fit your home’s décor, adding trim, matching bookcases or even built-in lighting. The bed’s name is attributed to William L. Diy platform bed with storage. Build a Full Storage (Captains) Bed. How to build a platform storage bed for under $200. Bed size. Single size bed Bed size refers to the dimensions of a mattress and the names by which standard sizes are called. Beds themselves vary widely in size according to the size of the frame and degree of ornamentation but are sold according to the size of mattress they take. The dimensions and names vary considerably around the world, with most countries having their own standards and terminology.

In addition, two mattresses with the same nominal size may still vary slightly in actual dimensions, due to manufacturing tolerances, level of padding, and support type. Table of common sizes[edit] Note: This table uses a conversion formula from international sizes and does not accurately reflect Australian standard sizes. Canada and United States[edit] Standard North American sizes Modern manufacturing conventions have resulted in a limited number of standard sizes of commercial bedding for mattresses and box springs. 'Free Woodworking Plans' Blog. Free Woodworking Plans On The Internet !

Frame-Miter Sled Plans. PLANS FOR A FRAME (flat) MITER SLED This page contains plans for the frame-miter table saw sled I use for cutting frame-mitered ring segments. I use sleds for cutting segments because they can quickly cut perfect segments that require almost no sanding. I usually cut segments for either 8-sided rings or 12-sided rings, depending on bowl diameter, so I designed the sled with a stationary fence, i.e., non-adjustable for angle. I made two fences, one fence for cutting 8-sided segments and another fence for cutting 12-sided ring segments. Swapping fences takes less than a minute. Click on any photo to enlarge it. My sleds are made from 1/2" Baltic birch plywood.

Making a Tumbling Block Cribbage Board - by WoodMosaics. Carport Project page 1. Arched Wooden Bridge project - page 1. I made this garden bridge in March 2002 and it is still standing strong today.