Tutorial Roboguide. Tutorial-Instalacion y Simulacion en Roboguide. Roboguide V9 Rev. H Full Registered. ROBOGUIDE V9 Crack www.100-sf.com. Estándares de rosca y tolerancias de agujeros roscados con macho. Tolerancia del macho vs. tolerancia de la rosca interior (tuerca) La tolerancia normal del macho es ISO 2 (6H) para generar un ajuste de calidad media entre tornillo y tuerca.

Una tolerancia inferior (ISO 1) genera un ajuste estrecho sin separación en los flancos entre tornillo y tuerca. Una tolerancia más alta (ISO 3) genera un ajuste grueso con mayor separación. Se utiliza si la tuerca tiene recubrimiento o si se prefiere un ajuste suelto. Entre las tolerancias 6H (ISO2) y 6G (ISO3), y entre 6G y 7G, también hay machos con tolerancia 6HX y 6GX. Las roscas de tubo tienen como referencia la normativa que se indica a continuación: Roscas G según ISO 228-1. Mecánica de taller. Allied - Allied Machine and Engineering - Industrial Holemaking Cutting Tools. Next Level Jobs - Ivy Tech Community College of Indiana. Select a campus near you for contact information on the following eligible non-credit programs.

Advanced Manufacturing Boiler Operator Maintenance Boiler Pressure Vessel Inspector Certified Production Technician (Manufacturing Skills Standard Council) Computer Numerical Control Operator Program with NIMS Certification Health Sciences Certified Clinical Medical Assistant (CCMA) Certified Clinical Medical Assistant (CCMA) (Online plus Clinical Externship) Information Technology & Business Technology A+ Certification Prep CompTia, A+, Network+ Mastering Project Management with PMP Prep (Online) PMP Certification Level 1 Scott Wilson Workforce Alignment Consultantgwilson88@ivytech.edu Kassandra Flanagan Workforce Alignment Program Managerkflanagan9@ivytech.edu Sarah Bierbaum Workforce Alignment Administrative Assistantsbierbaum@ivytech.edu Contact Krys Ardayfio Workforce Alignment Consultantkardayfio@ivytech.edu.

Ingeniería Mecafenix - Accueil. Mitutoyo Products. Proceso completo de fabricación del acero. OGPmultisensor. Fusion Large Field-of-View Measuring Systems. QVI Fusion QVI Fusion is an innovative multisensor measurement system that combines a unique large field-of-view (LFOV) optical system with available touchprobe, laser and micro sensors to form a uniquely productive metrology system.

The heart of Fusion’s capability lies in its LFOV optical system. Large field optics allow a wide area to be imaged with high accuracy, while QVI’s exclusive feature extraction can instantly process and identify all features and dimensions within the scene with no need for a pre-programmed measurement routine. Fusion’s AutoID capability allows any previously programmed part – or multiple parts - to be placed anywhere on the stage, even without fixturing, and Fusion will identify the parts and automatically measure them. QVI Fusion 350 is ideal for measuring 2D parts. QVI Fusion 400 is a high-performance multisensor system offering dual optical paths for instant switching between large field and high zoom imaging.

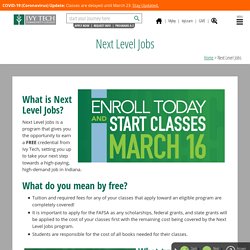

Measurement Volume. Tipos de roscas y cuerdas para tornillos tipos de cuerdas mas comunes. Representación de Elementos Roscados - Primera Parte. Revista Ferramental - Accueil. DirectIndustry - El salón online de la industria: sensores, automatismos, motores, bombas, manipulación, embalajes... Thread Tolerancing. Information on Screw Threads Tolerancing of Screw Threads It was previously stated that an essential principle is that the actual profiles of both the nut and bolt threads must never cross or transgress the theoretical profile.

Practically, to make a thread, tolerances must be applied to ensure that this essential principal always applies. Tolerancing of screw threads is complicated by the complex geometric nature of the screw thread form. Clearances must be applied to the basic profile of the threads in order that a bolt thread can be screwed into a nut thread. Usually nut threads have a tolerance applied to the basic profile so that it is theoretically possible for the nut thread profile to be equal to the theoretical profile. A full designation for a metric thread includes information not only on the thread diameter and pitch but also a designation for the thread tolerance class.

A tolerance class is made up of two parts, a tolerance grade and a tolerance position. Future Machines. Sistema de Bibliotecas. Mobile - MRO, Supplies, Tools & Solutions. Travers Catalogs. Versión digital de la revista Metalmecánica. Sandvik Coromant. Carbide inserts are used to machine almost everything made of metal.

The insert has to withstand extreme heat and force, so it’s made of some of the hardest material in the world. We take you to the Sandvik Coromant's world class insert production facility at Gimo, Sweden to witness how an insert is made. See how it's done! TranscriptAlmost everything made of metal is machined with an insert. The insert has to withstand extreme heat and force, so it’s made of some of the hardest material in the world. A typical insert is made of 80% tungsten carbide and a metal matrix that binds the hard carbide grains together, where cobalt is the most common. In the material warehouse, row after row of raw material are stacked.

Some recipes contain very small amounts of selected ingredients that are added by hand. In the milling room the ingredients are milled to the required particle size together with ethanol, water and an organic binder.