Antistatic agent. An antistatic agent is a compound used for treatment of materials or their surfaces in order to reduce or eliminate buildup of static electricity generally caused by the triboelectric effect.

Its role is to make the surface or the material itself slightly conductive, either by being conductive itself, or by absorbing moisture from the air, so some humectants can be used. The molecules of an antistatic agent often have both hydrophilic and hydrophobic areas, similar to those of a surfactant; the hydrophobic side interacts with the surface of the material, while the hydrophilic side interacts with the air moisture and binds the water molecules. Internal antistatic agents are designed to be mixed directly into the material, external antistatic agents are applied to the surface. Antistatic agents are also added to some military jet fuels, to impart electrical conductivity to them and avoid buildup of static charge that could lead to sparks igniting fuel vapors.

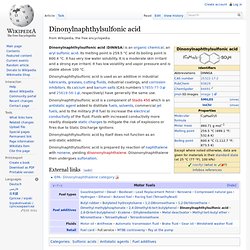

See also[edit] Notes[edit] Electrical Conductivity of "JP-8 + 100" Additives in Hydrocarbons and Fuels. High Production Volume (HPV) Challenge Program Test Plan and Data Review (DINNSA) Dinonylnaphthylsulfonic acid. Dinonylnaphthylsulfonic acid (DINNSA) is an organic chemical, an aryl sulfonic acid.

Its melting point is 259.5 °C and its boiling point is 600.4 °C. It has very low water solubility. It is a moderate skin irritant and a strong eye irritant. It has low volatility and vapor pressure and is stable above 100 °C. Dinonylnaphthylsulfonic acid is a component of Stadis 450 which is an antistatic agent added to distillate fuels, solvents, commercial jet fuels, and to the military JP-8 fuel to increase the electrical conductivity of the fluid. Dinonylnaphthylsulfonic acid by itself does not function as an anti-static additive. Dinonylnaphthylsulfonic acid is prepared by reaction of naphthalene with nonene, yielding diisononylnaphthalene. EPA: Dinonylnaphthalene category. The not-so-secret ingredient: Stadis 450 (dinonylnaphthalene sulfonic acid, barium salt) DRAFT FEB 09 – Please check for latest revision.

PDF version The most commonly used commercial turbine jet fuels today are named JET-A, JET-A1, and JET-B. All of these are kerosene type fuels except JET-B which is a kerosene-naphtha blend for colder climates [1, 2]. JET-A is used internationally and JET-A1 is available only in the US. Stadis® 450 - Innospec - Static Dissipator Additives. Enhance safety by preventing static charge build up Safety must always be the number one priority when refining or handling fuels.

When rapid fuel flow rates are combined with highly refined low sulfur fuels, electrostatic charges can quickly build up. Slow dissipation can be a potential hazard, as a discharge from an electrically charged fuel to the side of the tank can ignite the fuel vapor, causing an explosion. As fuels have become ‘cleaner’, the risks of electro-static ignition have increased. The high severity refinery processes used to remove trace materials from low sulfur fuels also reduce the natural conductivity of the fuel.

Innospec’s STADIS® brand is a class leading, non-metallic range of static dissipator additives (SDAs). The STADIS® range can be used to improve the conductivity of both ground and jet (aviation) fuels. STADIS® has been setting the standard in static dissipators for more than 30 years; trusted for use in aviation fuel since 1983. Our range includes: Stadis® 450 MSDS.