Discover How a Custom-Built Hautau Lathe Improved DOM Tube Production - Hautau. A long-held Hautau hallmark is its ability to custom-design and build tube and pipe cutting solutions to suit individual needs of specific businesses.

A perfect example is when PTC, a major Midwest producer of high-quality cold-drawn tubes needed to improve their tube cutting operations. Custom-Designed and Built Rotating-Head Cutoff Lathe Leads to Increased Production and Better Yield Because cold-drawn tubes vary in length, the business’s process couldn’t cut true random lengths. This led to wasted tube and profits. Plus, a secondary operation was needed for end chamfering, which required length and diameter setup and was limited to a single length. How Hautau Pipe Cutting Solutions Can Completely Change the Way You Do Business - Hautau. For many businesses, selecting a Hautau solution for their pipe cutting needs has meant an increase in efficiency and an equally impressive increase in their bottom line.

Whether you choose from our complete line of Rotating-Head Tube Cutoff Machines or require a custom solution, Hautau engineers have established a reputation for satisfying their customers’ needs and providing ongoing expert technical support. The Industry-Changing Rotating-Head Tube Cutoff Machine With Hautau’s tube-cutting and chamfering machines, you no longer need extra steps for deburring or secondary chamfering – regardless of whether you’re doing small batches or long production runs. Tube cutting machine is ideal for short runs - Hautau. A fabricator of hydraulic tube assemblies needed a more efficient way to cut and chamfer tubing for crimp fittings.

Their tube saws left burrs and small shavings, and their lathe-type cutoff machines couldn’t chamfer all tube ends. As a result, tube chamfering and de-burring operations were needed. Unique Tube Cutting Solution Also Improves Product Tracking - Hautau. A manufacturer of heavy truck driveshafts came to Hautau with a two-pronged problem.

The cutoff machines they were using were slow and took too much time to set up.Because there are three tubes of different lengths in a typical driveshaft, they needed a better way to track each tube group throughout the assembly process. Their previous practice of relying on paperwork and manual entry meant their production runs were often slowed to a snail’s pace. Hautau Offers a Better Way for Conveyor Idler Rolls - Hautau. Automated conveyors are essential for manufacturers, retailers and distribution centers throughout the world. It’s not unusual for the conveyors to literally have thousands of powered rollers and belt-driven idlers for smooth sorting and moving of products. With a traditional manufacturing method, the idlers require several steps for production. After the tube has been cut to its specific length, it’s then manually loaded onto a separate machine that will form the groves – which are crucial to advancing the product along the line.

A Better, Easier, and More Efficient Approach The Hautau method, though, is anything but traditional. With it’s rotating-head cutoff machine, a tube can be cut and grooved in one continuous cycle that takes 20 seconds to complete. CC80 Double End Bore machine - Hautau. Hautau endfinishing machines have powerful and precise servo-hydraulic tool feed to support heavy feed rates and continuous production applications.

Our robust machine frame plus heavy-duty hydraulic chucking ensures you'll meet tight-tolerance requirements and produce chatter-free bevels and bores. Tube OD: 0.20 inch to 8.7 inch Wall Thickness: .03 inch to 1.0 inch Tool Feed Travel: 3 inch Tool Feed Thrust: up to 6000 pounds. C80 8.7" Tube Beveler Machine - Hautau. C50 5" Tube Beveler machine - Hautau. Hautau endfinishing machines have powerful and precise servo-hydraulic tool feed to support heavy feed rates and continuous production applications.

Our robust machine frame plus heavy-duty hydraulic chucking ensures you'll meet tight-tolerance requirements and produce chatter-free bevels and bores. Tube OD: 0.50 inch to 5.0 inch Wall Thickness: .03 inch to 1.0 inch Tool Feed Travel: 3 inch Tool Feed Thrust: up to 6000 pounds. C30 3" Tube Beveler machine - Hautau. Tube Beveling and Chamfering Machines - Hautau. Dual Blade Shear Cutting Machine - Hautau. RC60 Rotary Cutoff Machine Advantages: The nick-and-shear tube cutoff method is a proven system for high-production cutting of thin-wall tube.

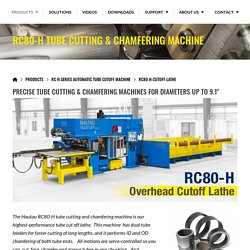

Here's how it works: The tube is clamped in precise dies that conform the the profile of the tube. RC80-H CutOff Lathe - Hautau. What are the benefits of combining tube cutting and chamfering into one operation?

If you currently saw a lot of tubes, and those tubes need to be deburred or chamfered after cutoff, you know that the extra tube handling and equipment setup can take more effort than the cutting operation. And if your production runs are short with frequent changeovers, having to setup the tube chamfering machine for each size will reduce your productivity. Our rotating-head tube cutoff lathe holds the tube stationary for cutting, then chamfers both tube ends before releasing the tube. This combines the cutting and chamfering into one operation and eliminates any secondary chamfering operations.

And because all the machine motions are programmable, changeovers are fast and setup time is virtually eliminated. RC60-H Cut Off Lathe - Hautau. RC50-H 5" CutOff Lathe - Hautau. Tube OD: 0.75 inch to 5.0 inch Wall Thickness: .02 inch to solid bar Cut Lengths: 0.75 inch min / 480 inches max • Multiple cut lengths per tube • Random lengths are automatically measured and optimized The 30HP cutoff lathe headstock has ample power for fast cutting, and includes constant surface speed (CSS) control to maintain optimum production rates.

The dual hydraulic chucks hold the tube on both sides of the cut and adjust automatically. Tube Cutting Machine - Hautau. Automatic Tube Cutoff Machine - Hautau. The Hautau length control system allows the operator to program up to ten cut lengths, and then choose the quantity and length combination with the shortest remnant.

Additional material savings comes from the ability to face the leading tube end instead making a trim cut, and from the ability of the tube feeder to handle very short remnant short pieces. And the first cut piece is within tolerance without adjustments. With the Hautau automatic tube cutoff machine, setup time for different tube diameters is fast a repeatable. All tube loading, feeding, chucking, and cutting motions adjust automatically when the operator keys in the tube size. Tube Cutting and Chamfering - Hautau. The Hautau RC80 Tube Cutting and Chamfering Machine is the largest of the RC line, with a 9.1 diameter capacity. If you cut and process steel tubes, the first step of your process is to load tube bundles and cut the tubes to precise lengths. The next step is chamfering the tube ends for safe handling and assembly. And you may need deep bevels for welding, radius cuts for press fits or even grooves for snap rings.

All these operations add to your production costs, including setup time, labor and extra work-in-process. Rotary-head cutoff machine that cuts tube and chamfers in one operation. High-Speed Automatic Cutoff Lathe - Hautau. RC30 Automatic Pipe Cutoff Lathe (3.0 inch) The Hautau RC30 Automatic Pipe Cutoff Lathe is the smallest of our rotary-head cutoff lathes to include full-range chucking, for high-speed cutting and chamfering of pipe or tubing up to 3 inches in diameter. If you are using a bandsaw or cold saw to cut tube or pipe, you know that the sharp edges have to be deburred, beveled or chamfered to produce high-quality workpieces.

Our pipe cutoff machines combine cut-off and complete endfinishing in one operation, and with our built-in software routines you can cut grooves, bores and weld-prep bevels. To ensure you get continuous production from your cutoff system, we build a full line of automatic tube loaders that handle full tube bundles safely and deliver single tubes into the cutoff machine. Our tube loaders all have automatic changeover for diameter, and they measure the length of each incoming tube for material optimization. Tube-cutoff-saw - Hautau. RC Rotating Head CutOff Machines - Hautau. Our rotating-head or rotary-head cut-off machines are the most advanced way to cut, face and chamfer tubes in one operation. Many conventional tube cutting systems are not precise and usually leave sharp tube ends, but our cutting machines produce burr-free tubes and maintain close tolerances.

Hautau cutoff lathes hold the tube stationary during the cut, so even bowed and bent tubes can be processed. The rotating head spins around the tube, and servos move the tools for cutting and chamfering. The tube is gripped by two chucks that position the tube for cutting.