Combustion Process in the Spark-Ignition Engine with Dual-Injection System. 1.

Introduction In these times injection is the basic solution of supplying of fuel in the Spark-Ignition (SI) engines. The systems of fuel injection were characterized by different place of supplying of fuel into the engine. Regardless of the sophistication of control system, the following types of fuel injection systems can be identified: injection upstream of the throttle, common for all of the cylinders – called Throttle Body Injection – TBI or Single Point Injection – SPI (Figure 1 a),injection into the individual intake channels of each cylinder – called Port Fuel Injection – PFI or Multipoint Injection – MPI (Figure 1 b),injection directly into the each cylinder, Direct Injection – DI (Figure 1 c).

Figure 1. Systems of fuel injection [1]:a) Single Point Injection, b) Multipoint Injection, c) Direct Injection; 1 – Fuel supply, 2 – Air intake, 3 – Throttle, 4 – Intake manifold, 5 – Fuel injector (or injectors), 6 – Engine 1.1. Figure 2. Figure 3. 1.2. Figure 4. Figure 5. Figure 6. Figure 7. Technical Information.

Clemson Vehicular Electronics Laboratory: Engine Control. The average new car has dozens of computers that control everything from the airbags and brakes to the lights and entertainment system.

However, when someone refers to "the car's computer," they are probably referring to the engine control module (ECM). The ECM generally employs the most powerful (and expensive) microcontroller in the vehicle. Engine control modules determine where to set the throttle, how much fuel to inject into the cylinders, and when to fire the spark plugs. In many vehicles this controller also regulates the electric power distribution, provides the on-board diagnostics, and communicates with a number of other automotive systems to share information it obtains from various sensors.

Engine control modules take data from a wide variety of analog sensors, digitize this information, and use it to calculate the proper engine settings. Today's ECMs generally employ 32-bit microcontrollers with a few megabytes of memory clocked at speeds between 32 MHz and 100 MHz. Quality Car Switches & Car Sensors. Combustion Process in the Spark-Ignition Engine with Dual-Injection System. MARINE ENGINE SYSTEMS. 1.1 Common terminology Before beginning this module, let’s look at some terms relating to internal combustion: 1-1 profile 1.2 Operating principles of engines There are two types of diesel engines, a four stroke cycle and a two stroke cycle.

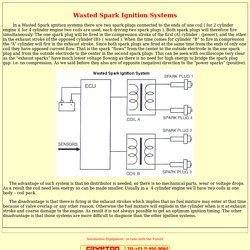

Four stroke cycle diesel engine In a four stroke cycle engine, four strokes of the piston are required to complete one cycle. Wasted Spark Ignition. Wasted Spark Ignition Systems In a Wasted Spark ignition systems there are two spark plugs connected to the ends of one coil ( for 2 cylinder engine )( for 4 cylinder engine two coils are used, each driving two spark plugs ).

Both spark plugs will therefore fire simultaneously. The one spark plug will be fired in the compression stroke of the first (A) cylinder - (power), and the other in the exhaust stroke of the opposed cylinder (B)- ( wasted ). When the time comes for cylinder “B” to fire in compression the “A” cylinder will fire in the exhaust stroke. Since both spark plugs are fired at the same time from the ends of only one coil they have opposed current flow.

The advantage of such system is that no distributor is needed, so there is no mechanical parts, wear or voltage drops. The disadvantage is that there is firing in the exhaust strokes which implies that no fuel mixture may enter at that time because of valve overlap or any other reason. Top Five Parts to Make Your Vehicle More Fuel Efficient - The Auto Parts Warehouse Blog. AutoPartsWarehouse.com shows consumers how to save gas money on their Labor Day travels and throughout the year by proper maintenance or replacement of 5 key vehicle parts Carson, CA –– August 27, 2013– AutoPartsWarehouse.com today released its list of the Top Five Parts to Make Your Vehicle More Fuel Efficient.

As Labor Day travel approaches, and national fuel prices hold strong at over $3.50 a gallon, finding ways to ensure fuel efficiency has become vital to protecting consumers’ wallets. So the experts at AutoPartsWarehouse.com have developed a list of the top five auto parts that can make the biggest difference in a vehicle’s fuel efficiency. When consumers think about fuel efficiency, they often think about driving behaviors associated with fuel savings — such as driving slower, or opening windows instead of running the air conditioning. And while driving behavior is critically important, APW reports that key vehicle parts can also have a significant impact.

Distributer and roter. Dwell angle.