What Type of Body Kit Material Should I Choose? If you're reading this, you've probably decided the factory stock appearance of your car, while attractive, is rather staid and unexciting.

You know that modifying your vehicle with a body kit is what feels right when it comes to adding a personal touch and making it your own. Maybe you're considering starting out slowly by adding a rear spoiler or front air dam, or going further with side skirts and even a replacement custom hood. The first decision you may need to make is the type of material you may want. Body kit parts come in fiberglass, polyurethane, ABS plastic, carbon fiber and composite. Some manufacturers specialize in one or two types, while others offer various kinds. Fiberglass Fiberglass parts are relatively easy to produce and inexpensive to buy, but their as-delivered fit and finish may not match those of polyurethane or ABS plastic parts. No VOC Fiberglass Alternative Boosts Manufacturer Production at Lower Cost - VersaFlex.

To boost productivity, Austin mounted a fiberglass chopper on the spray gun.

“Since the structural polyurea is so easy to apply with the spray gun mounted chopper and dries so quickly, we’re making product in about one-tenth the time we used to previously,” says Austin. NestEgg Trailers now uses the structural polyurea in about 75% of its fiberglass part-making processes, with the goal of fully transitioning over from polyester resins as soon as possible. According to Austin, however, one of the greatest benefits of switching to structural polyurea is how it expedites the process of making molds for parts. “The traditional moldmaking process, using polyester or epoxy resins, is very costly and labor intensive,” says Austin. “It can take weeks to hand lay the fiberglass.

Instead, NestEgg Trailers now uses the structural polyurea for the rapid prototyping of new designs or to cost effectively create production molds to increase production. 10 Futuristic Materials. Lifeboat Foundation Safeguarding Humanity Skip to content Switch to White Special Report 10 Futuristic Materials by Lifeboat Foundation Scientific Advisory Board member Michael Anissimov. 1.

Aerogel protecting crayons from a blowtorch. This tiny block of transparent aerogel is supporting a brick weighing 2.5 kg. Engineering foams look set to make a comeback. Slightly odd looking and – well – quirky, you can see that a recent partnership between Toyota and French design house, Studio Massaud, was about challenging convention.

The appearance ME.WE concept car certainly does that by using body panels made of expanded foam known as Arpro. The vehicle was designed with minimal weight in mind and realised that steel body panels would be just too heavy. Other materials such as aluminium, composites, plastic all offered disadvantages from cost to production, yet Arpro, seemed to tick all the boxes. There is no doubt that the concept car is aimed to evaluate the potential of using expanded foam type products as body panels and visual parts, and to quantify any weight or performance benefit. And once you get past the initial gasp, it actually makes a lot of sense. Arpro, manufactured by JSP, has been used for many automotive applications from bumpers to head restraints.

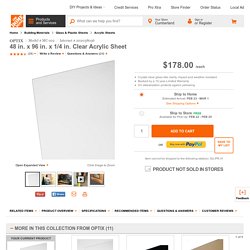

The materials is both lightweight and has very good energy absorption. Ecovative. Ultra lightweight sandwich panel technology. OPTIX 48 in. x 96 in. x 1/4 in. Clear Acrylic Sheet-MC-102. I needed glazing for two triangular shaped interior openings, to reduce sound transfer.

I decided on Plexiglas because I could cut it to fit. I was skeptical that a 4' x 8' sheet of clear Plexiglas could be shipped by truck without damage. OK, I didn't get notification that it had arrived, but within a few days I received the email to pick it up. I was absolutely amazed at the packing. The sheet (protected by a removable soft film) was wrapped in bubble wrap, sandwiched between full size corrugated cardboard, edge protected by thick cardboard strips, all inside a cardboard box. The sheet arrived in perfect condition, one of the flat cardboard protection sheets was used to make a full sizeRead More The sheet arrived in perfect condition, one of the flat cardboard protection sheets was used to make a full size template of the opening, and the cardboard protector strips served as risers while cutting the plastic with a circular saw with a fine tooth blade. Fiberglass , Epoxy , Composites, Carbon Fiber - U.S. Composites, Inc.

Rinspeed Bamboo. Goldcore Light: Quality Lightweight Plywood. Plywood for Marine, Motor homes, Construction and Commercial interiors. Bamboo Fiber Composites.