steven cheng

We ,Topworks Plastic Mold Company,are a China based company dedicated to offering Custom Made Plastic Design,Plastic Mold and Plastic Molding Services.

Untitled. Untitled. Untitled. Plastic Chair Mould manufacturer in China with back insert exchangeable,steel P20,718 - A China Plastic Chair Mould manufacturer and supplier,the back insert could be changed,steel:P20,718 with good price and quality… plastic chair mold:mold cavity:1runner:cold runnermold cavity steel:P20mold core steel:P20mold slider insert:DIN 1.2738 with NitridingCore insert activation:2 Hydraulic CylindersPlastic material:HDPE advantages: 1.Professional in make all kinds plastic chair mould,toilet seat mould and outdoor chair mould. 2.plastic chair mouldcwith High quality and competitive price. 3.Continuance service and technical support. 4.Rich experienced skilled workers. 5.Professional mould designer. 7.High quality,reliability and long product life of plastic chair mould. 8.Mature,perfect and excellence 9.On-time delivery of chair mould.

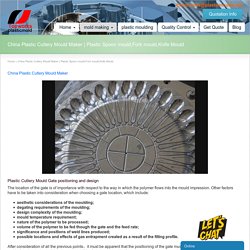

Plastic Spoon mould,Fork mould,Knife Mould - China Plastic Cutlery Mould Maker Plastic Cutlery Mould Gate positioning and design The location of the gate is of importance with respect to the way in which the polymer flows into the mould impression.

Other factors have to be taken into consideration when choosing a gate location, which include: aesthetic considerations of the moulding;degating requirements of the moulding;design complexity of the moulding;mould temperature requirement;nature of the polymer to be processed;volume of the polymer to be fed though the gate and the feed rate;significance and positions of weld lines produced;possible locations and effects of gas entrapment created as a result of the filling profile. After consideration of all the previous points,it must be apparent that the positioning of the gate must be determined relatively early on and before the design build-up has started.

PET mould,PET preform mould,PET bottle mould design - Cap mould ,lid mould and closure mould making company in China - We are dedicated to make the quality cap mould with mould steel ,P20,H13 and S136 .and our cap mould includes: hinged closures mouldyorker spout moulddisc-top cap mouldflip-top cap mouldpush-pull cap mouldtwist open/close cap mouldflapper closures mould Undercuts on the Inside of the cap Undercuts on the Inside of the cap are usually • Inside threads, • snap-on ribs (for cap, closure or lids of containers), or • major undercuts that are part of the product shape.

Inside Threads on cap Inside threads usually occur in cap but also may be designed in many technical products such as plastic pipe hardware, etc. Crate mould,turnover box mold,food/beverage packaging plastic mold - Plastic mold,China plastic injection moulding company and manufacturer-PIM. Safety aspects at injection molding plant-China injection molding company. It would be fairly safe to say that, if all aspects of good housekeeping were strictly observed , there would be very few accidents in the molding shop.

Unfortunately,good housekeeping is often sacrificed in the cause of keeping production going, sometimes with disastrous results. Spillage of granules on the floor has already been mentioned, along with leakages of oil. The combination of granules, oil, and water often met in the molding shop. the floor can be almost lethal. Oil spillages are sometimes soaked up with rags and sawdust which are then left on the floor for hours, or even days at a time. It only requires a cigarette end or a spark to start a serious fire. Proprietary materials are available for soaking up oil and rendering it almost non- inflammable but it really is best not to spill it in the first place. Early attention to leaks and the use of a drip tray during maintenance work will do much to avoid this hazard.

Flexible pipes and leads Machine guards Ventilation Lighting Air lines. How to price plastic mold tool - Many buyers who purchase injection molds from China are solely focused on saving money.

However, this isn’t the right attitude to take, since you’ll ultimately want a mold that works properly and is reliable, instead of just being cheap. How much a plastic mold tool will cost is dependent on several different factors. You should, therefore, request the information when getting a quote.The checklist below details the various areas of interest that you need to consider when purchasing a mold: For instance, a three plate or hotrunner may be more expensive at first, but unlike two plate tools, they don’t need anyone to operate them or separate the runner. This will mean that you save money on the piece part price, even though the tool cost is higher. With this information in hand, you will be able to calculate the costs for yourself, and see just why some companies set their prices higher or lower. Don’t put the full responsibility for tool buying on your purchasing department, though. 4 Steps To Help Getting An Accurate Plastic Mold and Plastic Parts Offer From China.

With the continuous improvement of the level of mold manufacturing and mold workers’ skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories.

The continuous deepening of information exchanges between the two sides has greatly promoted the development of China’s mold industry. For those buyers who often purchase in China, it is simple to deal with China’s mold and injection molding suppliers. But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China’s mold factories outside of thousands of miles. Language and technical communication constitute two significant obstacles. For many people who bought customized plastic parts in China for the first time, they were completely unfamiliar with this industry. Also, this industry is technology-intensive, the quotation requires suppliers and buyers to have a good interaction. In fact, this is incorrect. #1 China overmolding company for insert molding,co-injection,2k molding,double color molding,multi shot mold#1 China overmolding company for insert molding,co-injection,2k molding ,double color molding,multi shot mold -

Topworks plastic ,A China overmolding company for insert molding,co-injection,2k molding,double color molding,multi shot mold.

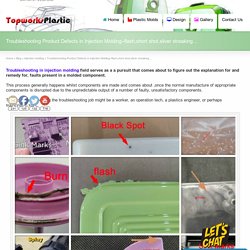

What overmolding we supply? Blow molded parts from China-Tooling 40% lower, Molded part 30% reduced - Troubleshooting Product Defects in Injection Molding-flash,short shot,Silver Streaking... Sprue Bushing Nicked, Rough, or Poor Seating In the event the sprue brushing is nicked, coarse, not really sitting, it might bring about materials to decay.

The reason behind this can be that the material is caught in place (until it finally overheats) within a section of the mold that maintains high temperature. The degraded material turns into fragile and may destroy to be loose, coming into the soften stream and appearing as dark-colored dots or streaks. Examine the interior surface area of the sprue bushing. Clear away any grazes or other flaws. Burnt Materials Due to Inappropriate Ventilation Incorrectly venting areas appear with a white ashing around the mold steel or the charring of the material. This can be from the burning of air captured inside the mold and squeezed to the situation of combustion. Track down vents in the mold at areas 1 in. (25.4 mm) away from each other all along the circumference of the cavity on the static half. Whenever extra venting can be done, get it done. Plastic molding and plastic mold design-FREE EXPERT CONSULT and SUGGESTIONS. Radii There are two main causes of plastic part failure: molded-in notches, and sharp internal corners.

These are largely caused by designers failing to provide the part with a sufficient internal radius to avoid the issue. Plastic Injection Molding Manufacturers Near Me,China Vendor-30 % COST REDUCED,200 pieces batch accept. Plastic Molds from Topworks Mold-35% COST LOWER,15 DAYS LESS. Many people assume that Chinese plastic injection molds are going to be poor quality.

However, a huge number of companies- including multinational corporations- still choose to buy such plastic molds. Does that mean these companies are naive or making a mistake? Of course not. In fact, Topworks plastic mold company ,as one of China plastic mold manufacturers, is capable of making some of the best molds on the market- for a much lower price(35% COST LOWER,15 BUILDING DAYS LESS) than European and American companies can possibly offer. Across China, the plastic injection mold manufacturing industry is growing from strength to strength.

Not only do we have the skills required to make superior injection molds, but we also possess excellent English skills for technology and business. Plastic mold company from China,plastic injection molding,one stop service,best price.