programme info : Additive Manufacturing International Conference, Bringing together the world leaders in Additive Manufacturing Monday 7th - Friday 11th July, 2014 The full programme for the event will not be available until closer to the conference, but to assist delegates with travel arrangements, please find below provisional timings. Monday 10:00 Introduction to AM Master Class14:00 Overview of research activities within Universities19:30 Pre-conference reception buffet (including advance conference registrations) Tuesday

DIY Stereolithography 3D Printer RAPID 2012 The RAPID 2012/3D IMAGING Conference and Exposition is known worldwide as a must-attend event. It’s the place to learn the basics as well as explore the newest technologies and materials in additive manufacturing in combination with 3D imaging. This is the largest industry forum for the presentation and discussion of the latest developments, trends and techniques specific to additive manufacturing, rapid technologies, 3D printing and 3D imaging. Learn about cutting edge applications of these technologies in several diverse industries including: Revolutionize your product design Reduce time to market Create prototypes in a fraction of the time of traditional methods Cut costs Eliminate tooling Manufacture functional demonstration parts Produce low volume end-user parts and components Pre & Post-Conference Activities Conference Sessions Rapid Technologies & Additive Manufacturing Community Activities

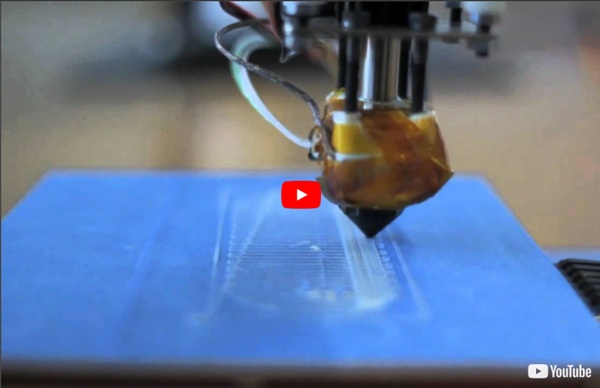

Build a Laser 3D Printer - Stereolithography at Home Here is how to make a Stereolithography 3D Printer. It is still a bit of a work in progress but so far it is working pretty well. This is mainly an experiment which started as a Delta Robot Stereolithography Printer but ended as a more traditional Cartesian Stereolithography Printer. "I'll be honest, we're throwing science at the walls here to see what sticks. No idea what it'll do." - Cave Johnson Stereolithography (SL or SLA from Stereolithography Apparatus) is an additive manufacturing process using a vat of liquid UV-curable photopolymer "resin" and a UV laser to build parts one layer at a time. I have wanted a 3D Printer for a while now and there are some very reasonably priced kits available like the Makerbot, Ultimaker and the RepRap project. I decided to enter this in the Epilog Challenge Contest because I could really use a laser cutter :-) I also have some ideas how to redesign this project, for creation on a laser cutter. This project is Open Source Hardware.

Additive Manufacturing Research Group Tab 1 AMRG Academic wins Industrial Secondment 25th June 2013 Dr Darren Watts wins an industrial secondment award from The Royal Academy of Engineering, joining the CAE division at Majenta PLM Ltd. looking at the industrial application and implementation of CAE simulation. RAEng awards webpage News archive » Tab 2 PhD Studentships in Additive Manufacturing / 3D Printing now available 1st February 2013 A unique opportunity for UK & EU residents to undertake a fully funded PhD studentship in the internationally recognized AMRG at Loughborough University. Read more / apply here » Smart Material Structures by UC Industry is seeking feasible low cost methods for the fabrication of metal-matrix structures. ArtiVasc 3D Developing vascularised scaffolds for soft tissue engineering using state of the art AM techniques.

3D printed replicas of people and pets from Captured Dimensions I met Jordan Williams at the Inside 3D Printing Conference and Expo. When I asked him what he did he pulled out a tablet and showed me this: That’s him holding a 3D printed bust of himself. Jordan creates high-resolution 3D scans of people (and their pets) and has them 3D printed. Throughout history sculptures have been made of people, though usually of or for wealthy people. Jordan runs a startup called Captured Dimensions and he just revamped the website, so we exchanged a few emails about the company. Jordan: We make our models of living subjects using the process of Photogrammetry. 3DP: That sounds expensive. Jordan: There was a great deal of trial and error throughout the initial phases of our setup. 3DP: What print services do you use? Jordan: Throughout development, we have sourced prints through several providers such as Shapeways, Sculpteo, local companies, etc. Related

Additive Manufacturing Users Group (AMUG) The Revolution will be Caramelized - The CandyFab Project