https://www.lindemhe.com/product/electric-counterbalance-forklift/

Related: dubeprashant • lindemheanalytics • kamlaharris321INTERNAL COMBUSTION FORKLIFTS OR ELECTRIC FORKLIFTS? When it comes to buying or renting an industrial forklift, you will be faced with the choice between an internal combustion engine vs an electric forklift engine. When your business depends on forklifts, it’s essential that you research your options before you go ahead with the purchase. The differences between electric and internal combustion lift trucks are plenty.

A Comprehensive Checklist To Choose The Right Stacker For Your Warehouse - Linde Material Handling A stacker, also known by multiple names such as stacker trucks, electric stacker, pedestrian stackers, etc depending upon manufacturers, can basically be thought to be younger versions of forklifts. They are one of the most commonly found material handling equipment & warehouse equipment in factories and warehouses. They are used to lift and move pallets of goods and to load and unload them at heights. As compared to a heavy duty diesel forklift the stacker is an ideal choice for operating in smaller and confined spaces dealing in lightweight materials. Some models are used to move un-palletized goods like machine parts, boxes, drums, and cartons. Although forklifts are suitable for heavy-duty operations, when it comes to parking space, stackers occupy lesser area than say, a diesel forklift.

4 Important Types of Material Handling Equipment used in the Construction Industry The importance of material handling in the construction industry is paramount. A fully functional construction site would heavily rely on various vehicles and machinery like a heavy-duty diesel forklift, to perform at an optimal pace and deliver proper results. Material handling in this context refers to the following things; a. Timely movement of building materials b.

4 Important Types of Material Handling Equipment used in the Construction Industry The importance of material handling in the construction industry is paramount. A fully functional construction site would heavily rely on various vehicles and machinery like a heavy-duty diesel forklift, to perform at an optimal pace and deliver proper results. Material handling in this context refers to the following things; a. Timely movement of building materials

Understanding different types of forklifts and their applications Forklifts are an essential equipment in material handling processes for all industries. They have a wide range of applications that make them a top investment for any company. Forklift is an automated platform truck that basically helps in carrying and moving loads that are too heavy for humans. But despite the straightforward objective, forklifts come in a variety of options, with each option serving its own unique purpose. As important it is to buy a forklift, it’s also important to understand what kind of forklift will best suit your material handling needs. Sure, your main objective is to get the load from A to B, but that’s not just it.

Maintenance Tips For Forklift Batteries This article is intended to help you extend the life of your forklift batteries while enhancing the performance of your forklift. The article aims to educate forklift operators to better manage and maintain an electric battery forklift. Every battery can work only for a limited cycle. The recommended practice is to recharge the battery after every 8 hours of usage or when it drops down to 30% or less. On the contrary, charging the batteries frequently or as per convenience can cut short the battery life.It’s better to let the forklift battery charge to 100% every time you charge it.Do not drain your forklift battery beyond 80%Do not let a discharged battery sit for too long as this could result in the formation of sulfur on the battery plates, leading to reduced battery life.Also, maintain the room temperature while charging batteries as the rise in temperature potentially damages the battery.

Safety Precautions to Reduce Risk of Falling from Order Picker - Linde Material Handling Order Pickers are designed to take the forklift operator up to the rack & stack the load. Unlike the Electric Stacker which is used for storing and retrieving loads from racking at short heights, an order picker is designed with a platform for the operator to stand on and easily access inventory at greater heights. They can commonly be found at warehouses requiring high stacking of products. Since an order picker requires vertical maneuvering and walking into & out of the cabins, there is always a risk of the operator falling from a height. In order to avoid such accidents, there are a few safety precautions that could be followed. To start with, the operator must hold a valid order picker license and should practically demonstrate safe operating skills.

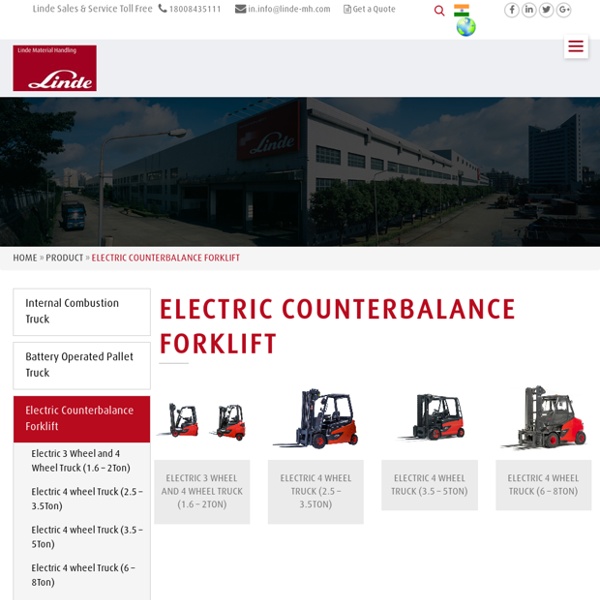

Forklift Selection-Most Common Types of Forklifts and Their Uses Be it in a warehouse, a construction site or any other business, moving heavy stuff like machinery is an everyday affair. There are a host of Forklift types that is available in the market like – electric forklift, electric stacker, battery forklift etc. But with so many types to choose from, picking up the one that best suits your business and environment may need careful study. Counterbalance forklifts are best used for material handling: These types of forklifts have two trucks that counterbalance each other.

7 Easy Hacks to Operate a Forklift Safely Forklifts are the essential components in most of the warehouses and workplaces to lift heavy loads, transport them and stack them to their places. Be it a diesel forklift or an electric one, these highly helpful machines can quickly turn into destructive weapons if used without the right safety measures. As such, there are quite a few easy to remember techniques which can prove to be useful to the longevity of the men as well as the machines. 1.

Benefits of lithium-ion powered material handling equipment Electric vehicles or EV have become a new standard for innovation across various industries, especially material handling. Apart from having environmental benefits, they have shown tremendous success with heavy-weight applications and quite promising results for the long run. Every material handling equipment manufacturer today offers electric options for a variety of equipment like electric stackers, electric forklift and electric reach truck. With the rapid advancements battery technology, electric vehicles are becoming more and more reliable.