Online | Skill Set: Making A Butterfly Spline (Or “Arikata”) For our Woodworking Skill Set theme, we asked MAKE contributor Len Cullum to contribute some pieces on understanding basic tools and techniques. Here, he presses into service some of the tools covered in previous articles. — Gareth Now that we’ve skimmed the surface of woodworking tools, perhaps we should put some of them to work. Below, we’ll outline the process for making the butterfly spline, known in Japanese as “arikata.” When working with wider, thicker slabs of wood, it is not uncommon to have checking (cracks) in the surface, particularly at the ends. What We’ll Be Using: Cracked piece – Port Orford CedarSpline piece – 1″ x 2″ x 3/8″ cherrySharp chisels – 1/2″ and 1″Marking knifeSharp PencilRouter with 1/4″ straight bitAdjustable squareAngle gaugeHammerGlue and brush The first thing you will want to determine is how many splines you need. Start with making the spline. Once the spline is cut, determine its position along the check. If the fit is good, carefully pull it out. Related

Hand Cut Double Dovetail Experiment - by Woodhacker @ LumberJocks.com ~ woodworking community - StumbleUpon After admiring the double and double-double dovetail joints that are capable with the Incra and other jigs, I started thinking, “Why not try this by hand?” So this box is my first experiment with handcut double dovetails. It took me some time to figure out the joinery process, but once I realized a few things about this type of joint, it seemed do-able. It was quite challenging but also a ton of fun. In this blog, I’m focusing on the sides of the box, but here’s a few pictures of the nearly completed box - Materials.For this box’s sides I used three types of primary contrasting woods, although there is no real reason to do so. The picture below shows the rabbet joint cut on each end of each side – I set the rabbet depth at 1/8” and cut it on my router table. Below is a top-view picture of the pieces in relation to each other once they become integral to the box. The close-up below shows in more detail. The Tails.Most often I cut my tails first, pins second. Ready for pins – At last!

Fascinating Lamps by Calabarte | Pondly Calabarte is the pseudonym of a Polish artist named Przemek Krawczynski, whose art takes on a peculiar but incredibly beautiful form: cool lamps. The name itself is a portmanteau of two words – art (obviously), and calabash, the fruit that carries his imagination. The calabash is a bottle gourd originating in India, although Calabarte gets his supply from Senegal. Due to ancient domestication and usage, the bottle gourd has an incredibly tough outer shell. Due to the combination of dark, thick material with a light source within, the primary art of his work, however, shines in the dark. Hard work, beauty, an exceptional degree of detail and a marriage between mathematical geometry and a rampant imagination – all imprinted onto the husk of a Senegal calabash. Described as the art of light, Calabarte’s artistic tendencies truly took off in 2009, when he made his first gourd lamp, by chance of coming across a calabash. Website

AW Extra - Dream Workbench - Woodworking Projects Tired of working on a sheet of plywood thrown over a pair of sawhorses? Had it with rolling benches that wiggle and wobble? Hate running around your shop whenever you need a tool? Our dream bench starts with traditional workbench features like a thick top, a sturdy base, bench dogs and a pair of vises. Our bench is built to withstand generations of heavy use. The thick, butcher-block-style top is truly a joy to work on. Tools & Materials If you go all out like we did you can expect to pay about $900 for materials. You could build adjustable shelves inside the cabinets instead of drawers and pullout trays. The best thing is you can cut costs and still get a fully functional bench right away, even if you go with the least expensive options. To build the bench you'll need a tablesaw, planer, belt or orbital sander, a router and a circular saw. Build the Cabinet Cut the plywood parts for the three individual boxes (Parts D and E) and assemble them (Photo 1). The Top Install the Vises Sources:

The DIY $20 brake bleeder The $20 DIY Brake Pressure Bleeder You've heard me extol the songs of brakes and brake fluid, and how its important to change it every two years. I'd like to take credit for this idea, but I got it from this page. - Here's another one too. And his idea was good. Look, here's the same thing I made for less money.... wow $114.99 LESS!!! You'll need some basic hand tools and a Dremel with a stone cone-shaped bit or a drill and a set of bits. You'll want to use a NEW sprayer tank, don't go grabbing whatever you see in the shed, or was used last summer to kill weeds. This pressure bleeder will (like all of them) will fill your master cylinder up to the very top. last wheel your bleeding, to close the pressure line on the bleeder with the switch on the handle of the tank, and then vent the pressure in the tank. This little ditty will work wonders for your VW's brakes, or hydraulic clutch on your VR6 or Vanagon.. well, just about any European car! Home

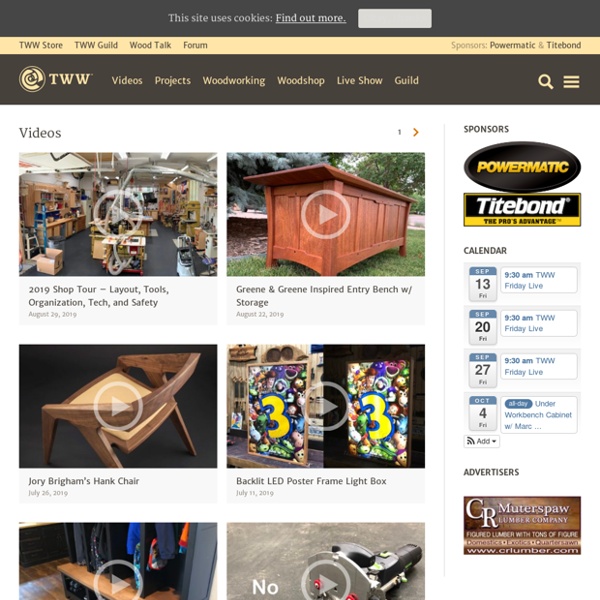

Apple Universal Dock Tray by Hekseskudd Modern-day Gentleman’s Tray The design team at Hekseskudd re-envisions the classic gentleman’s tray as not just a convenient container for loose change and keys, but one that also caters to the modern user by providing a place to recharge and house electronics like the iPhone and Apple keyboard. 3 configurations of varying size, capacity, and functionality are available in a number of handsome wood finishes for a custom made feel that compliments the heritage of the classic product. Designer: Hekseskudd Fusionknots.com 55 Great Sites For Woodworkers :Construction Management Schools: Construction Management Degree Do you have a love for woodworking? Having a husband that loves working in the garage and two sons in woodshop at school, I decided to put this list of sites together to help them as well as help others. From the novice to the advanced, if you are looking for some tips and tricks, design ideas, or just want to see what others are doing, this list has what you are looking for. These sites are not listed in any order other than by general topic. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. – Chris Baylor is the woodworking guide for About.com. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 48. 49. 50. 51. 52. 53. 54. 55.

Electronics 2000 - Hobby Electronics - Software, Calculators, Technical Data, Pin-outs, Beginners Guide, Forum, Links... How to Build an Adirondack Lawn Chair - Plans for Building an Adirondack Chair It's a good thing that so many plastic patio chairs are designed to stack, and the aluminum ones fold up flat. That means we can get them put away and stored out of sight as quickly as possible. But, if you think outdoor furniture should enhance your yard and garden, consider a chair that evolved on the porches of summer homes and resorts of upstate New York. Our version has come a long way from the early types that had flat backs and seats -- and, we've added a matching table so you'll have a stylish surface for cool drinks and a good book. If you're building more than one chair, it pays to make templates for parts like the side rails, arms and back rails. Model designed in Alibre Design Xpress. View a larger version of this animation or Download printable plans of the Adirondack chair and table. Making the Chair Seat Lay out the side-rail shape on your stock, cut to the lines with a jigsaw [1] and sand the edges smooth. Use a 1-in. Then install the outer two slats [8].