Sacramento Public Library - 3D Printer Policy and Procedure

Purpose The Library desires to offer community access to new and emerging technologies such as 3D printers to inspire a new interest in design and help the community to bring their creations to life. This policy establishes how and under what circumstances the public may use the Library’s 3D printers. Policy The Library’s 3D printers are available to the public to make three-dimensional objects in plastic using a design that is uploaded from a digital computer file. The Library’s 3D printers may be used only for lawful purposes. Procedures The procedure for printing from the Library’s 3D printers is as follows: Design creation: The 3D printer can be used with basic knowledge of Computer Assisted Drawing (CAD). Definitions 3D printing: the process of making a physical object from a digital model. 3D Printer: A 3D printer uses melted plastic to produce objects designed on a computer.

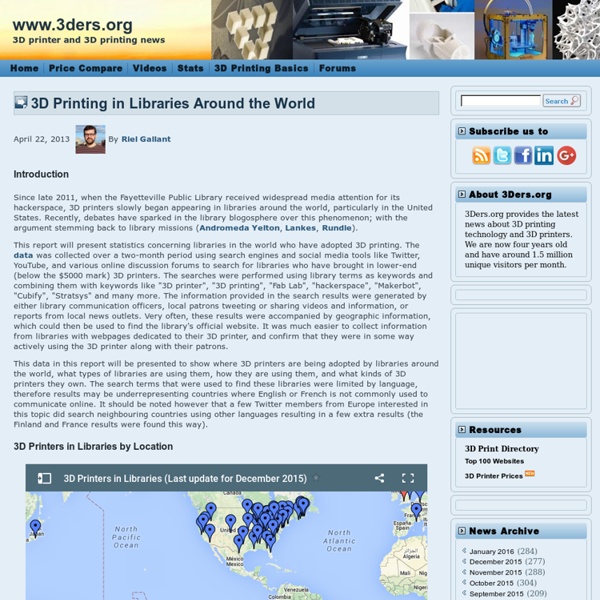

Why Your Library May Soon Have Laser Cutters and 3-D Printers

Ben Wiseman Visit the downtown branch of the Chattanooga Public Library and you'll find the usual stuff: rows of books, magazines, and computers. But walk up to the fourth floor and there's something unexpected. It's a “makerspace”—complete with a laser cutter, a zine lab for making paper publications, and a 3-D printer. When it opened in spring 2013, the maker floor—formerly unused and filled with decrepit equipment—became a massive hit, and up to 1,200 patrons attended events there. Chattanooga and Cleveland aren't the only cities giving this new kind of library a try. Ezra Reynolds is an example. But what about books? You have to give the librarians credit.

3D Printers Available For Public In Chicago Libraries

<img src="<a pearltreesdevid="PTD2153" rel="nofollow" href=" class="vglnk"><span pearltreesdevid="PTD2154">http</span><span pearltreesdevid="PTD2156">://</span><span pearltreesdevid="PTD2158">pixel</span><span pearltreesdevid="PTD2160">.</span><span pearltreesdevid="PTD2162">quantserve</span><span pearltreesdevid="PTD2164">.</span><span pearltreesdevid="PTD2166">com</span><span pearltreesdevid="PTD2168">/</span><span pearltreesdevid="PTD2170">pixel</span><span pearltreesdevid="PTD2172">/</span><span pearltreesdevid="PTD2174">p</span><span pearltreesdevid="PTD2176">-</span><span pearltreesdevid="PTD2178">cafODhhaQOlCs</span><span pearltreesdevid="PTD2180">.</span><span pearltreesdevid="PTD2182">gif</span></a>" style="display:none" height="1" width="1" alt="Quantcast" /> None

3D Printing

With a 3D printer for public use and Maker programs every month, your Library is the place to bring your ideas to life. Make It @ Your Library "Think left and think right and think low and think high. Using the 3D Printer Thanks to a grant from the U.S. Design your 3D Object: Use a 3D modeling software to create your object. More Information Take a look at our FAQ. For inspiration and downloadable 3D files, visit thingiverse.com, Trimble 3D Warehouse, yeggi.com. Should your library try 3D printing?

3-D Printing and Scanning

The Fab Lab has 3-D printers, available for public use. The Library offers classes on the basics -- and more -- of 3-D printing. The Fab Lab also has a 3-D scanner available for public use. You can find out more about the 3-D scanner below. 3-D Printer What do I need to use the 3-D printer? A library card, a filled-out form and your object formatted in an .stl file. Printing costs are $.05 per gram (of object's weight) plus a $1 charge. What's the process for using the 3-D printer? On-demand services are currently on hold. For more information about 3-D printing, scanning and reservations, you can also check out the 3-D Printing and Scanning Policy. 3-D Scanner The Fab Lab offers a 3-D scanner to create electronic files of physical objects. What do I need to use the 3-D scanner? Scanning costs are $5 an object. What's the process for using the 3-D scanner? Fill out one form per item in person in the Fab Lab. Have other questions? Back to Labs at DC Public Library

Naperville Public Library | Adult Services | 3D Printer

3D Printer - Frequently Asked Questions 1.What is Desktop 3D Printing? 3D printing, also called additive manufacturing, means making things layer by layer according to a 3D design file. 2. 3.How much does it cost to print something? 4.If I hand you a 3D print, can I watch it being printed now? 5.Can I use the 3D printer and print it myself? 6.What kinds of objects can I print? Go to Thingiverse.com and download a pre-made file You can digitize your own object and 3D print it to a larger or smaller scale You can sculpt your own object by using our 3D modelling software (Blender, 123D Design, or 123D Make) 7.How can I turn in a 3D print file? 8.How big of an object can I print? 7.What colors can I print in? b.The printer will only print an object in one color.

3D Printing at the Library

3D Printing at the Library The Portsmouth Public Library is home to two hardworking 3D printers: A MakerBot Replicator named Gutenberg and a Flashforge Creator Pro named Ada! Click their portraits above to read more on the library blog. We write monthly updates with tips, tales and trials of 3D printing. With access to this new technology, the Library plans to foster tinkering, collaborative learning, intergenerational learning, play, experimentation, problem solving and creation. What will you make? Frequently Asked Questions Why 3D Printing? 3D Printing is becoming more and more common in manufacturing, design and commerce. Using our 3D Printing service might: Show a high school student that she has an affinity for design, inspiring her to choose it as a career after she graduates. Why plastic? In choosing our 3D Printer, we wanted to find one that used an environmentally-friendly, cost-effective material (filament). Why did you name it Gutenberg/Ada? We had a contest. Policies 1. 2. 3. 4. 1.

The Age of the Makers; 3D Printing in the Public Library of Cologne « IFLA Public Libraries Section Blog

Cologne’s first publicly accessible 3D printer can be found in the central library at the Neu-markt. Twice a day it is demonstrated how the printer works and people can print out 3D print files which they bring along. The price depends on the weight of the object produced by the printer. The movement of makers – an initiative on the internet – is a movement of people who want to create things themselves. The 3D printer is an important tool, as it allows people other than professionals to be active in the area of design.

Piscataway Public Library

Arduino is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. The kits allow beginners to create and program electronic devices. “Arduino is an open-source electronics prototyping platform based on flexible, easy-to-use hardware and software. It’s intended for artists, designers, hobbyists, and anyone interested in creating interactive objects or environments." Source: Arduino Website, "Within the next 5 to 10 years, the Arduino will be used in every school to teach electronics and physical computing — that’s my prediction. Makey Makey Kits MaKey MaKey is an invention kit for the 21st century. Piscataway Library offers : Arduino Education KitsMakey Makey boardsRaspberry Pi boardsPico Boards Supplier: SparkFun Electronics