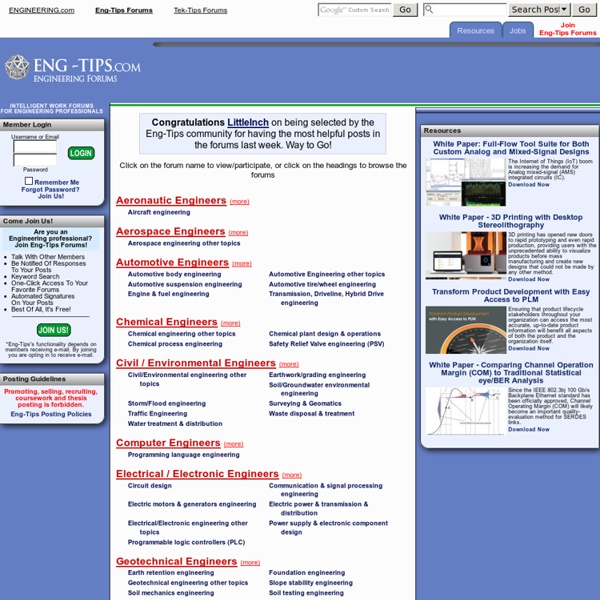

Eng-Tips Engineering Forums

Engineering ToolBox

Studio Tips: Acoustics Forum

AllExperts Questions & Answers

Online Social Skills Guide - Improve Your Social Skills

FREE Rhyming Dictionary - Find Rhyming Words in Seconds

English to French, Italian, German & Spanish Dictionary - WordReference.com

Vocabla

TermSciences - Terminologie Scientifique

FSRabat.Com | Partage des Cours et Exercices filières : SMPC SMIA et SVT S1,S2 Faculté des sciences Rabat

Related:

Related: