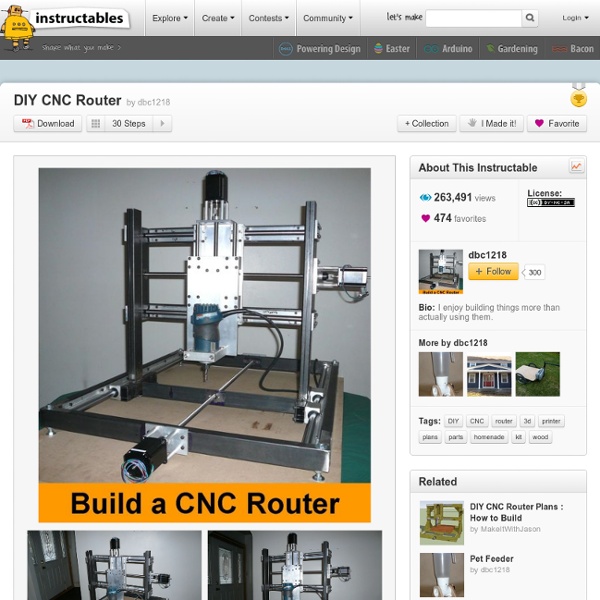

DIY CNC Router

If you have any interest in purchasing a kit version of this machine please click the above button and complete the form so that I can gauge the level of interest. This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc. I have designed this router to be very versatile and hope to also use this same machine as a 3-D printer and a hot wire foam cutter in the future. For those of you who already know about CNC routers here are the specs for my machine. This video is a time lapse of the assembly of the router, an hour and half condensed into 45 seconds. There is also a video of the very first test of this machine on the last step.

Techno

cnc | esuli.it

I have finally managed to edit the video of my DIY plotter, I hope you enjoy it! As you can see from the video, I have put the electronic inside the scanner, and I have improved the pen holder. I have also found an acceptable solution for cables of steppers, and added a reset/halt button. DIY plotter, Arduino and grblShield inside the scanner body DIY plotter closed. Now the plotter is a self-contained device, with just USB and power plugs (Arduino is power by the USB, the grblShield by a 12V 3.3A power source got from an old monitor). To sum up the experience of building this plotter I want to list all the resources that have been useful/necessary for me to complete it. A picture of John Moses Olano (yes, it’s me with a John Fitzgerald Kennedy/Barack Hussein Obama/Franklin Delano Roosevelt/George Walker Bush -style name). All this stuff to draw something on a piece of paper. UPDATE: see the video and get more info on the whole project. The hunt for steppers is producing the first victims

Building a CNC router

This instructable will show you how I built my CNC router. I hope you can draw some inspiration from my build and that this instructable will be helpful for your future projects. This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. After doing some research I decided to design and build my own machine. Please note: I built this CNC router as final project for school (also called 'profielwerkstuk' in the Netherlands).

CNC Cookbook: Blog Posts for Jan thru Mar 2007

January Through March 2007 CNC Blog Archive Diagnosing and Curing Noise Problems in CNC Machinery After backlash, the second biggest source of frustration seems to be noise problems on homebrew CNC systems. I added a new Cookbook page aimed specifically at gathering up the wisdom I've found for dealing with noise problems. Quit Drilling With Your Tailstock in the Lathe Widgitmaster made up these nifty drill holders that will fit in a QCTP holder: He's got one with a chuck in it too. One thing about using the QCTP to hold these is you will have to dial them into the center of the workpiece. I'm going to be making some drill and chuck holders for my gang tooling plate after I get it made. Handy Pre-Ground Parting Off Tools from eBay Somehow I forgot to mention I'd found these really handy parting off tools on eBay: Read my mini-review of them on the parting off page. Making a Timing Pulley Saw this approach to creating a timing pulley by drilling holes and thought it was clever: EZClamps Done!

Related:

Related: