Deltaprintr 3D Printer Kit. 3Drag 3d printer. The Specs in Brief Print area: 200 x 200 x 200 mm PLA, ABS & more. ø 3 mm filament Diameter of nozzle 0.5 mm, Accuracy X/Y: 0,015 mm – Z: 0,39 µ Printing Speed 200 mm/sSee the full specs on RepRap Wiki Fully Open Source3Drag is fully open source, all electronics and schematics are available under the GPL 2.0 License.

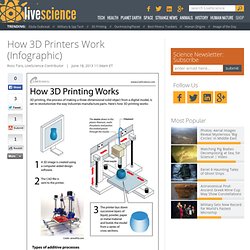

Mounting instruction and Bill Of Materials are openly available .Access all the info on RepRap Wiki Downloads and Configurations Access all the Software and Firmware needed and see how to configure your 3Drag at best. Access to all the Software you need and understand how to optimize.See the configuration guide More contents: If you want to enable CNC features on your 3Drag, see here. The Low Cost Prototype Builder's Pick and Place Machine. How 3D Printers Work (Infographic) 3D printing, the process of making a three-dimensional solid object from a digital model, is set to revolutionize the way industries manufacture parts.

First, a 3D image is created using a computer-aided design software (CAD). The CAD file is sent to the 3d printer. The printer lays down successive layers of liquid, powder, paper or metal material and builds the model from a series of cross sections. Printrbot: Your First 3D Printer by Brook Drumm. I designed the Printrbot to be the simplest 3D printer yet.

There are some great kits out there - the Makerbot, the Ultimaker, the Prusa Mendel, and others - but none as small and simple as the Printrbot. This all-in-one 3D printer kit can be assembled and printing in a couple of hours. Other kits will not only take you many more hours to build, they will also have hundreds more parts, and they will cost more. RigidBot 3D Printer by Michael Lundwall. Check our updates tab for the most updated information.

**Now all $299 pledges and above have a heated bed! See stretch goals** Upgrade options - We have several upgrade options to add even more value to your RigidBot. RigidBot 3D Printer by Michael Lundwall. Bukito Portable 3D Printer - Take it everywhere! by Diego Porqueras. If you missed out on this Kickstarter project, you can visit Deezmaker.com for more information on how to get a Bukito See updates: Colors Strips, Aluminum plates, Heated Platform, LCD, Carrying Case and more!

The Bukito is our new sturdy, fast and portable 3D printer. This new 3D printer design is the result of the desire and passion to make a great portable printer that we can take with us anywhere. Build Volume: 5"x6"x5" (125mmx150mmx125mm)Resolution: <50 microns (0.05mm) X/Y & 100 microns (0.1mm) ZNozzle Size: 0.5mmFilament Diameter: 1.75mm (No special cartridge needed)Speed: 150mm/sec - 350mm/sec Materials*: PLA, ABS, MABS, Nylon, LaywoodPower: Includes 110-240 Power adapter. Runs with 12-16v for battery power (battery not included)Weight: ~6lbsController: Panucatt's custom Azteeg series board (Arduino Compatible)Software: G-Code compatible (Using Marlin Firmware) / Free Open Source programs like Repetier Host or Pronterface "We got to witness its stability first hand.

High Quality. Modular Desktop CNC Machine by AJ Quick. What is CNC?

A CNC is essentially a machine that is controlled by a computer and can perform highly intricate maneuvers over and over again (similar to a printer). In this case instead of dispensing ink onto the paper, it uses a cutting tool to cut very detailed shapes into common materials like wood, plastic, & aluminum. It is a critical machine in any manufacturing factory, or research and development lab. We think it’s a tool that will be found in every workshop and home garage in the future. We want to make that future a reality! The Pitch In August 2010 we pitched an idea to University of Minnesota staff to create a challenge for five graduating seniors in the field of Mechanical Engineering. Our Project Our CNC Machine is 26” by 20” with a useable cutting area of 18” x 12”. The Othermill: Custom Circuits at Your Fingertips by Otherfab. Share this project Done Share Tweet Embed Tweet Share Email.

The Peachy Printer - The First $100 3D Printer & Scanner! by Rinnovated Design. Below is a detailed video explaining how the Peachy Printer works through explanation and demonstration!

The peachy printer is a Photolithographic printer. That means it uses a controlled beam of light to cure light sensitive resin into hard objects. The peachy moves a laser beam along the X and Y axes to create the shape of the object, while using a drip system to control the level of the resin on the Z axis which determines the height of the object. The object you want to print must first become a 3D model in Blender. The software we wrote as an add on to blender takes the data from that 3D model and translates it into an audio waveform.

Now let's talk about the drip system that creates movement on the Z axis. Robox : Desktop 3D Printer and Micro-Manufacturing Platform by C Enterprise (UK) Ltd. Works Out of the Box – Plug in the power and USB cord and start printing.. automated bed levelling, intuitive software and advanced hardware all come together to make Robox reliable and easy to use.High Resolution – Robox has one of the highest print resolutions of any FFF printer in the market - 20µm (0.02mm) layers.Dual Nozzle System for Speed - Robox includes a dual-nozzle system which closes the flow of material and lifts the unused nozzle.

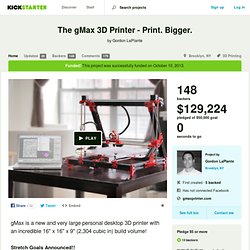

Up to 300% faster than our competitors.Automatic Material Recognition, No Vendor Lock-in - Robox requires no programming for different materials – just load the SmartReel and go! Each reel contains a chip which is programed with all the necessary parameters. You can load and programme these reels yourself or buy them loaded with filament ready to go.Quick-Change Head – The removable head system allows you to change the function of Robox quickly and easily. Want something that you can just plug and print? Fed up with high priced consumables? Play. Robox-store. The gMax 3D Printer - Print. Bigger. by Gordon LaPlante. If we reach: Read About gMax Printer At: Imagine a world where you can come up with a design in your mind and have the physical object, large or small, in your hands with just a few clicks on a computer in the comfort of your own home or office. 3D printing is something that I was interested in long before I designed the gMax printer.

Studying and working in architecture, I’ve been interested in building and design since childhood. Winter 2010 is when I bought a Prusa RepRap kit from the usual sources, and started assembling in my free time. Throughout this process I was working full-time and taking my exams to become a licensed architect, which I completed July 2012 – the first prototype was completed that Winter and I’ve been continuously updating, upgrading, and optimizing this printer ever since. NEXT GENERATION 3D PRINTER EXTRUDERS: THE RUGGED-HPX LINE by Dglass 3D. RUGGED-HPX1: Single Extruder Plug-and-playAll-metal & precision bearing gearbox 2:1 gear reduction = greater torque & print qualityLightweight design results in higher quality & higher speed printing Durable design provides trouble-free printingInfinitely adjustable retraction 1.75mm or 3mm filamentLocally sourced parts, hand assembled by D3D team. QU-BD One Up - Open Source Production Ready 3D Printer by Chelsea Thompson.

The Buccaneer® - The 3D Printer that Everyone can use! by Pirate3D Inc. Manufacturing timeline and Stretch goals sections are at the very end for those who just want to go there. FAQ is also at the back, do check it out in case the questions you have are already answered there. Hi everyone! We have had many requests to see the internals of our 3D printer while it is printing. Printrbot: The Perfect Beginner 3D Printer Can Expand Itself. There are a host of 3D printers out there, but none are as simple and inexpensive as the Printrbot created by Brook Drumm. It’s still in Kickstarter mode, but as of this writing,( the Printbot has already met the pledge goal. So we’re going to be seeing some of these in the future, and I know I already want to get my hands on one. There are a lot of different Printrbot kits you can order right now by pledging funds to the project: Some kits have only the basic parts, and no electronics, while some are even sparser, not even containing motors and hardware.

I suppose if you got a bunch of hardware lying around and want to buy the electronics yourself that’s a good way to go, but Brook will offer a kit for $499 that includes everything you'll need to build it. For somebody looking to get going right away that’s probably your best bet, and it’s a lot cheaper than a MakerBot--and you can be printing in under 2 hours. What’s the first thing you would print with one of these? [Kickstarter] 3D Printer.