University of Huddersfield proposes universal language for additive manufacturing. Researchers from the University of Huddersfield in the UK are developing a new language to help streamline the additive manufacturing process.

According to Dr Qunfen Qi, a research fellow at Huddersfield’s EPSRC Future Advanced Metrology Hub, “The research can provide a smart language that enables designers, [additive manufacturing] engineers and inspectors to truly communicate with each other in an intelligent, robust and productive way.” Through improving these connections across the whole production chain, it is expected that the universal language will enhance the productivity of 3D printing, with implications for greener manufacturing. Rewriting the rules of manufacturing At present, digital means of 3D model sharing and processing are in abundance. Advanced Solutions, Inc. Visualization. Chameleon Family. Multiphoton microscopy demands laser technology that is simple to use, yet flexible enough to allow you to explore the widest range of wavelengths and fluorophores.

With the release of the new Chameleon Discovery, Coherent now truly offers the most powerful and flexible range of ultrafast technology designed for completely hands-off operation. Chameleon Discovery is a high power, one-box, wide tuning range, dual output laser for MPE. Industry-leading femtosecond lasers. Medical Case Study: CTI Renato Archer. “We needed highly accurate, multi-material 3D printers; the Fortus adapts well to industrial applications and the Connex is useful in medical applications.” — Jorge Vicente Lopes da Silva, head of the 3D technologies division in Renato Archer’s Information Technology Center Skull reconstruction Renato Archer used its Fortus 3D Production System for its durable materials.

Connex technology helps Renato Archer develop medical prototypes that require flexibility with its range of rubber-like materials. Renato Archer’s Information Technology Center also serves hundreds of area hospitals with its 3D printing capabilities. Innovation and scientific rigor drive Renato Archer researchers’ every step. CTI has used Stratasys 3D Printers since 2005. ROWIAK GmbH - Photons at Work: MyFemto. The surgeon’s skills, his experience and his creativity must be supported by equipment which is designed to meet his induvidual needs.

The tools have to fulfill the surgeon’s special demands and should be adjustable until they feel like a part of his own body. Femtosecond Lasers have opened a new dimension in ophthalmic surgery. Two forces drive the future of femtosecond lasers in ophthalmology: The experience and the creativity of the surgeon and the congenial manufacturing of physicists and engineers. Outstanding surgical procedures can be performed in many different ways, depending on the experience and the skills of the surgeon. Ophthalmic surgery has extremely high requirements in regar to precision and safety. The machines are highly standardized for economic and for safety reasons. LLS ROWIAK LaserLabSolutions GmbH: TissueSurgeon. Product Brochures & Application Sheets.

Wyss Institute. Guiren wang. Continuous liquid interface production of 3D objects. Additive manufacturing processes such as 3D printing use time-consuming, stepwise layer-by-layer approaches to object fabrication.

We demonstrate the continuous generation of monolithic polymeric parts up to tens of centimeters in size with feature resolution below 100 micrometers. Continuous liquid interface production is achieved with an oxygen-permeable window below the ultraviolet image projection plane, which creates a “dead zone” (persistent liquid interface) where photopolymerization is inhibited between the window and the polymerizing part. We delineate critical control parameters and show that complex solid parts can be drawn out of the resin at rates of hundreds of millimeters per hour.

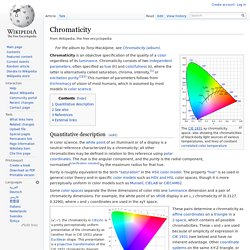

These print speeds allow parts to be produced in minutes instead of hours. Although three-dimensional (3D) printing is now possible using relatively small and low-cost machines, it is still a fairly slow process. Science, this issue p. 1349. Chromaticity. Quantitative description[edit] In color science, the white point of an illuminant or of a display is a neutral reference characterized by a chromaticity; all other chromaticities may be defined in relation to this reference using polar coordinates.

The hue is the angular component, and the purity is the radial component, normalized[clarification needed] by the maximum radius for that hue. These pairs determine a chromaticity as affine coordinates on a triangle in a 2-space, which contains all possible chromaticities. The 3 things you should know about hashCode() In Java, every object has a method hashCode that is simple to understand but still it’s sometimes forgotten or misused.

Here are three things to keep in mind to avoid the common pitfalls. An object’s hash code allows algorithms and data structures to put objects into compartments, just like letter types in a printer’s type case. Axolotl embryonic development of heart. POSITIONS AVAILABLE. Three positions are open, all related to the same project.

A $32M, 5-year project funded by DARPA and the NIH was launched last summer with the aim of creating a game-changing paradigm for drug discovery and development. The project includes teams at MIT, Draper Laboratory, as well as tissue engineering/device/pharma/biotech companies, and is aimed at creating a platform that supports ten interacting micro-organ systems and associated sensors for assessing cellular responses to inflammatory cues and therapeutic interventions. [1] Technical Assistant, Reproductive Engineering We are looking for a self-motivated technical assistant to join a team in the laboratory of Dr. Linda Griffith in the Biological Engineering department at MIT in collaboration with Newton Wellesley Hospital, under the aegis of the Center for Gynepathology Research and the DARPA Microphysiological Systems Program.

A BS in bioengineering, biology, chemistry, or related technical discipline is required. JUST RELEASED! FY14 DOD CDMRP OCRP & LCRP Program Announcement(s) - wmondy - Gmail.

Laser Zentrum Hannover e.V. Biofabrication Group Work of the group focuses on: Laser-based generation of structures (scaffolds) from biocompatible materials for tissue engineering using two-photon-polymerization Replication of these structures from biological materials via molding “Printing” of living cells in specific patterns for investigations on cell-cell and cell-environment interaction Three-dimensional cell “printing” to generate biological tissue Current scientific work and projects:

Laser Zentrum Hannover e.V.