Apprendre la charpente. Woodworking. Fabriquez des meubles ... Atelier du Bricoleur : conseils techniques sur le travail du bois par un passionné, en français et en anglais. Menuiserie. Matériel libre. Cet article est une ébauche.

Vous pouvez partager vos connaissances en l’améliorant : Compléter l'article Restructurer le contenu Rajouter des illustrations Créer des pages Alerter dans les discussions si le sujet n'a pas lieu d'être et veiller à ce que la ligne éditoriale de ce wiki soit bien respectée Le Matériel "Libre", C'est quoi? Le matériel libre est tout aussi important que le logiciel libre, si ce n'est plus! Le concept de matériel libre vient d'abord du monde de l'informatique, mais il s’étend à tout autre domaine touchant la vie humaine.

Miter Joint Corner Clamp. Gluing a miter joint is a challenge .

There just isn't an easy way to clamp it. The store-bought clamps I've tried in the past didn't always pull the joint together. Adding a Hidden Compartment - Woodworking Project. Adding a Hidden Compartment.

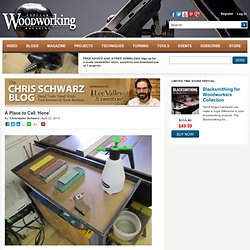

A Place to Call ‘Hone’ When I think of all the things that improved my sharpening skills, two things loom large.

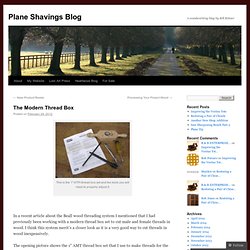

No. 1 is practice, of course, but close behind that is a dedicated sharpening tray. About 14 years ago I built a shallow tray from scrap plywood, nails and glue. No fancy joinery, no water-resistant materials and no finish. The tray sat beside my bench and contained all my sharpening mess, keeping it off my workbench and project parts. Débutants, utilisez vos deux mains gauches et créer vos propres meubles. The Modern Thread Box. This is the 1"-6TPI thread box set and the tools you will need to properly adjust it.

In a recent article about the Beall wood threading system I mentioned that I had previously been working with a modern thread box set to cut male and female threads in wood. I think this system merit’s a closer look as it is a very good way to cut threads in wood inexpensively. The opening picture shows the 1” AMT thread box set that I use to make threads for the “Mini Moxon” twin screw vises that I make. This set, along with several others was purchased at an auction many years ago and sat on a shelf until recently. AMT is not in business anymore, but these thread box sets are still being made and sold by many woodworking tool suppliers and they come in sizes up to 1 1/2″. The set includes the thread box made of maple I think, the taper tap and handle and instructions. Here you can see the tap in use on red oak.

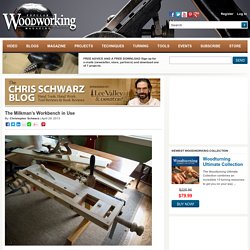

The Milkman's Workbench in Use. The Milkman’s Workbench – a portable bench I built for the June 2013 issue of Popular Woodworking Magazine – is about 653 percent better than my first workbench.

Thanks to the clever engineering in the portable bench, it can handle most handwork tasks when clamped to a dining room table or kitchen countertop. My first workbench – a heavy door on sawhorses – could do only a fraction of these task. To demonstrate its capabilities, I attached the portable bench to my dining room table. Formation et valorisation des techniques de charpente traditionnelle. La Charpentologie appliquée. John's Blog World. 1001 Pallets. Basic Construction & Carpentry Techniques. Woodsmith Tips — Tips, Techniques, and Videos from Woodsmith & ShopNotes.

Woodworking for engineers. AW Extras 4/17/14 - Simple Kitchen Upgrades - Woodworking Projects. Pull-Out Trash Drawer Whoever decreed that the trash can goes under the sink got it wrong.With plumbing in the way,there’s no space for a good-size can.

Plus who likes to bend over and reach into the cabinet? Here’s a great alternative: In one cabinet,replace the shelves with a simple trash can holder mounted on drawer slides.By attaching the existing cabinet door to the front of the pull-out unit,you create a convenient trash drawer. Fig.C and the photos at right show how to build the unit. Melamine board—particleboard with a tough plastic coating—is a good material for this project because it’s easy to clean.A 4x8 sheet costs about $25 at home centers.The melamine coating,however, tends to chip during cutting.This chipping is worst where the saw teeth exit the material. You’ll also need iron-on edge banding ($6 at home centers) to cover the exposed edges (Photo 2).

Use the same drawer slides you used for the drawers. Sources Woodworker’s Hardware, wwhardware.com, 800-383-0130. Fig. 1. Getting screws to hold in end grain. Because wood is relatively weak perpendicular to its grain, screws don't hold that well when screwed into the end grain.

This firstly because the thread has a harder time cutting into the grain fro the side, and also because what it does grab shears out more easily, as the shear is cross-grain. Wood screws do, however, hold extremely well in cross grain. So the trick to making screws really hold in the end of a piece of wood is to give them a bit of cross-grained wood to bite into. The easiest way to do this is to put a hardwood plug into the wood, 5/8" or 3/4" in diameter.

My First Project. Hello everyone.

I have finally taken the plunge and made something after weeks of reading and research here and on other websites. I stumbled across David Savage's website with lots of useful information on what tools to start with. Ceruser/patiner. Woodwork. Atelier du Bricoleur : conseils techniques sur le travail du bois par un passionné, en français et en anglais. Woodworking for engineers. Palette. Palettes.