Earthbag Building: The Next Big Thing? Earthbag building has just received engineering approval.

This is probably the greatest news ever for earthbag building. You can read more about this exciting breakthrough on our Earthbag Building Blog. This blog post has more details: Specifics of Nabil Taha’s Engineered Earthbag Designs For those who don’t know, earthbag structures are constructed with bags of moist soil or other suitable materials, stacked in courses like masonry and then tamped solid. As they dry, they turn into incredibly strong walls. First, let’s take a look at the larger picture to better understand what’s taking place in the natural building movement.

Production builders, manufacturers, suppliers and others who profit from modern building materials claim these materials are the easiest to use and most practical. The explosion of information on the Internet has fueled rapid-fire innovation in all areas, including alternative ways of building. The History Of Earthbag Building. A Short History of Earthbag Building by Kelly Hart The idea of making walls by stacking bags of sand or earth has been around for at least a century.

Originally sand bags were used for flood control and military bunkers because they are easy to transport to where they need to be used, fast to assemble, inexpensive, and effective at their task of warding off both water and bullets. Step-by-Step Earthbag Building. This Instructable explains each main step of construction for building vertical earthbag walls.

Videos on my Earthbag Natural Building YouTube channel demonstrate the process. For those who don’t know, earthbag building uses polypropylene rice bags or feed bags filled with soil or insulation that are stacked like masonry and tamped flat. Barbed wire between courses keeps bags from slipping and adds tensile strength. The final plastered walls look just like adobe structures. Thousands of people are now building with bags to create their dream homes, home offices, shops, resorts, rootcellars, storm cellars and survival shelters.

How to Build an Insulated Earthbag House. For those new to earthbag building, please read my Step-by-Step Earthbag Building Instructable .

Also, my new Earthbag Building Guide and Earthbag Building DVD are now available. Energy performance on most buildings can be improved with insulation, including those made of earth such as adobe and earthbag structures. Although most earthen structures are located in hot, dry climates, there is increasing demand for low-cost, eco-friendly earth building techniques in cold climates. How to Build an Earthbag Roundhouse. Note: If you’re new to earthbag building, please read the introductory Step-by-Step Earthbag Building Instructable first.

Also, my new Earthbag Building Guide and Earthbag Building DVD are now available. Stay up-to-date on all the latest earthbag news by following our Natural Building Blog. We built this earthbag roundhouse in 2010 as part of an earthbag workshop in Thailand, and finished it later that summer. Roundhouses are perhaps the simplest, fastest, easiest earthbag structure to build. We’re extremely pleased with the results, especially in terms of strength and cost. The other key advantage of earthbag is cost. Basic project information: 18’ exterior diameter; 15’ interior diameter; 177 sq. ft. interior floor space; total cost of materials: $2,045, which is about $11.50/square foot.

Superadobe & Earthbags - What Is Superadobe? Superadobe (sandbag and barbed wire) technology is a large, long adobe.

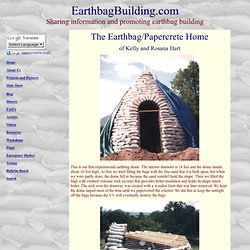

It is a simple adobe, an instant and flexible line generator. It uses the materials of war for peaceful ends, integrating traditional earth architecture with contemporary global safety requirements. Long or short sandbags are filled with on-site earth and arranged in layers or long coils (compression) with strands of barbed wire placed between them to act as both mortar and reinforcement (tension). Stabilizers such as cement, lime, or asphalt emulsion may be added. This patented and trademarked (U.S. patent #5,934,027, #3,195,445) technology is offered free to the needy of the world, and licensed for commercial use. Earthbag & Papercrete Home: Hart House. This is our first experimental earthbag dome.

The interior diameter is 14 feet and the dome stands about 16 feet high. At first we tried filling the bags with the fine sand that it is built upon, but when we were partly done, the dome fell in because the sand couldn't hold the shape. Then we filled the bags with crushed volcanic rock (scoria) that provides better insulation and holds its shape much better. The arch over the doorway was created with a wooden form that was later removed. We kept the dome tarped most of the time until we papercreted the exterior. Here is the same dome as above, with joists in place for the loft and with the arch form still supporting the entrance arch.

This is the beginning of the large elliptical dome that became our kitchen and living room. Because of the elliptical shape, this dome required a rigid pole framework to help support the second story. Here I am applying a coating of papercrete to the outside of the large dome. Earthbag Construction. EarthBag Homes - you're standing on the building materials... earthbag home Long sandbags are filled on-site and arranged in layers or as compressed coils.

Stabilizers such as cement, lime, or sodium carbonate may be added to an ideal mix of 70% sand, 30% clay. The Mud - Earthbag Building. How to Build an Earthbag Dome. Low-Cost Multipurpose Earthbag Building - DIY. Related Content Earth Building in Thailand I had heard there are thousands of new earthen houses in Thailand.

Our Earthbag House - How to buid a fortress on the cheap. Earthbag Natural Building: Video. Earthbag Homes Videos. Triple Dome Survival Shelter « Earthbag House Plans. April 12, 2011 by Owen Geiger Triple Dome Survival Shelter (click to enlarge)

Sweet Little Earthbag Home. Earthbag Lodge with Domes. Soil Tests For Earthbag Building (PDF) Resources for Earthbag Building. Suppliers of Bags Globally China Forest Packaging Group Co. ,Ltd www.forestpackaging.com Tel: +86 151 656 64026 Fax:+86 536 827 3455 Bill Chen, Sales Manager chinaforestpackATgmail.com Bill Chen does communicate in English. This factory in China (and Cambodia) can provide a wide range of polypropylene bags, both as individually sewn bags, and as long tubes on a rolls. They ship via containers (or partial containers) and have delivery to Haiti. Standard 18"X30" bags run about $0.11US each and the longer 18"X34" bags are about $0.12 each. The long tubing in rolls are 3500 meters (11,150' or 2.2 miles) long. They can supply gussetted bags by special order, and it would be necessary to give them exact specifications for this. They need up to 30 days lead time to fill orders.

Earthbag House Plans - Small, Affordable, Sustainable. Earthbag Building: Free Rootcellar Plan. Earthbag Building Index. Earthbag House Building.