Press release: Terminator polymer that regenerates itself. 13 September 2013 Scientists in Spain have reported the first self-healing polymer that spontaneously and independently repairs itself without any intervention.

The new material could be used to improve the security and lifetime of plastic parts in everyday products such as electrical components, cars and even houses. The researchers, from the CIDETEC Centre for Electrochemical Technologies in San Sebastian, have dubbed the material a 'Terminator' polymer in tribute to the shape-shifting, molten T-100 terminator robot from the Terminator 2 film. The research is one of the first articles published in new Royal Society of Chemistry journal Materials Horizons. Self-healing polymers that can spontaneously achieve quantitative healing in the absence of a catalyst have never been reported, until now. The polymer behaves as a Velcro-like sealant or adhesive, displaying an impressive 97 per cent healing efficiency in just two hours.

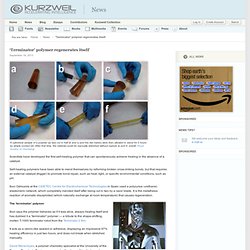

References Contact and Further Information. The "Terminator" polymer: I'll be back. Catalyst-free room-temperature self-healing elastomers based on aromatic disulfide metathesis - Materials Horizons. ‘Terminator’ polymer regenerates itself. A cylindrical sample of a polymer (a) was cut in half (b and c) and the two halves were then allowed to stand for 2 hours by simple contact (d).

After that time, the material could be manually stretched without rupture (e and f). (credit: Royal Society of Chemistry) Scientists have developed the first self-healing polymer that can spontaneously achieve healing in the absence of a catalyst. Self-healing polymers have been able to mend themselves by reforming broken cross-linking bonds, but that requires an external catalyst (trigger) to promote bond repair, such as heat, light, or specific environmental conditions, such as pH. Ibon Odriozola at the CIDETEC Centre for Electrochemical Technologies in Spain used a poly(urea–urethane) elastomeric network, which completely mended itself after being cut in two by a razor blade. T-1000 terminator (credit: TriStar Pictures) The ‘terminator’ polymer Source: Royal Society of Chemistry. Cidetec. Cidetec. ‘Terminator’ polymer can spontaneously self-heal in just two hours. In the future, we may praise the computer repairman on his needlework.

After all, the self-healing power of skin has served life very well over the years; it could be just as powerful in other contexts, too. If we surrounded the most sensitive computer components with a sac of soft material, air- and water-tight, repairs could end with the technician suturing shut a scalpel hole. Researcher Ibon Odriozola at CIDETEC Centre for Electrochemical Technologies has created a polymer that has the potential to lead to such a future.

The material is comprised of a poly (urea-urethane) elastomeric matrix, a network of complex molecular interactions that will spontaneously cross-link to “heal” most any break. In this context, the word “spontaneous” means that the material needs no outside intervention to begin its healing process, no catalyst or extra reactant. A good self-healing material has been one big challenge for artificial skin, something that can quickly stop up small wounds on its own. First reported self-healing polymer that spontaneously and independently repairs itself. Scientists in Spain have reported the first self-healing polymer that spontaneously and independently repairs itself without any intervention.

The new material could be used to improve the security and lifetime of plastic parts in everyday products such as electrical components, cars and even houses. The researchers have dubbed the material a 'Terminator' polymer in tribute to the shape-shifting, molten T-100 terminator robot from the Terminator 2 film. The research is published in the Royal Society of Chemistry journal Materials Horizons. Self-healing polymers that can spontaneously achieve quantitative healing in the absence of a catalyst have never been reported, until now. The scientists prepared the self-healing thermoset elastomers from common polymeric starting materials using a simple and inexpensive approach. A video shows that the permanently cross-linked poly(urea-urethane) elastomeric network completely mends itself after being cut in two with a razor blade.