1b Fluid power - 2nd p-point pres.ppt. 1a Fluid power - 1st p-point pres.ppt. Engineering Data - Lehigh Fluid Power Lehigh Fluid Power. Seal Guide. J and H Weight Chart. H and W Weight Chart. Assignment 2. Hydraulics & Pneumatic Simulators and Hydraulic Training Workshops. “What I touch I understand” Do your students spend hours tearing down components to see how they work?

Once the components are torn down is it possible for them to figure out exactly how they work as complete assemblies? Also, when components are in pieces do the students lose sense of how close tolerances really are so they can appreciate how important good filtration is? Narration, graphics, animations, tearing components down are good, but when it comes to really understanding how they work, there is nothing that will help a student get the job done with more clarity and speed than a fully-functional cutaway model of an actual hydraulic component. It’s the most powerful teaching aid in any classroom and it’s intuitive - many students will study a cutaway model and know how it works before the lecture even begins. Anyone can take a hydraulic component and cut it away. Lightweight – heavy components are difficult for students to handle and limit visual access.

Gear Pumps. Double-acting cylinder - Direct control. Linear actuator. Conceptual design of a basic traveling-nut linear actuator.

Note that in this example the lead screw (gray) rotates while the lead nut (yellow) and tube (red) do not. Floppy disc drive with leadscrew and stepper motor. A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required.

Hydraulic or pneumatic cylinders inherently produce linear motion. Types[edit] Mechanical actuators[edit] A mechanical linear actuator with digital readout (a type of micrometer). Roller screw actuation with traveling screw (rotating nut). Mechanical linear actuators typically operate by conversion of rotary motion into linear motion. Some mechanical linear actuators only pull, such as hoists, chain drive and belt drives. Hydraulics and Pneumatics. External gear pumps. Standard gear pumps generate high pressure ripples and therefore hydraulic noise.

As the teeth mesh they exhaust the fluid in a characteristic flow ripple dependent on the form of the gear face. Any machining errors or tolerances on the gear face can also manifest themselves in the fluid as noise. The amplitude of the pump ripple is dependent on the number of teeth on each gear. More teeth will give more ripples of lower amplitude. Although dependent on the resonant frequency of the machine this will generally reduce the noise level generated by the equipment although it will be at a higher and possibly more annoying frequency.

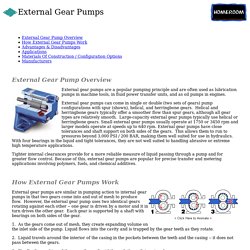

Pump manufacturers often provide quiet versions of external gear pumps based on one of the following approaches. Phased gears providing 2 times 12 teeth. Zero backlash design where teeth act individually rather than in pairs. Modified gear form pumps. External Gear Pumps. External Gear Pump Overview External gear pumps are a popular pumping principle and are often used as lubrication pumps in machine tools, in fluid power transfer units, and as oil pumps in engines.

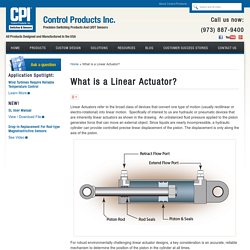

External gear pumps can come in single or double (two sets of gears) pump configurations with spur (shown), helical, and herringbone gears. Helical and herringbone gears typically offer a smoother flow than spur gears, although all gear types are relatively smooth. Large-capacity external gear pumps typically use helical or herringbone gears. Small external gear pumps usually operate at 1750 or 3450 rpm and larger models operate at speeds up to 640 rpm. External gear pumps have close tolerances and shaft support on both sides of the gears. Linear Position Transducers in Linear Actuators – by CPI. Linear Actuators refer to the broad class of devices that convert one type of motion (usually rectilinear or electro-rotational) into linear motion.

Specifically of interest to us are hydraulic or pneumatic devices that are inherently linear actuators as shown in the drawing. An unbalanced fluid pressure applied to the piston generates force that can move an external object. Since liquids are nearly incompressible, a hydraulic cylinder can provide controlled precise linear displacement of the piston. The displacement is only along the axis of the piston. For robust environmentally challenging linear actuator designs, a key consideration is an accurate, reliable mechanism to determine the position of the piston in the cylinder at all times. Pump School's Rotary Pumping Principles. Category:ISO 1219. Reference_identification_iso_1219_en_81346.pdf.