Grand St. Creative Technology Marketplace : Shop, Pre-Order and Beta Products. The Media Computing Group : Back to Tools The original FabScan was developed by Francis Engelmann in his Bachelor's thesis (cost of materials: 150 Euros).

FabScan 100 further reduced material cost so that you could build one for just 100 Euros. FabScan Cube then featured an improved housing, as a result of a student group working on interactive assembly. FabScan Pi is the latest version. It includes a Raspberry Pi embedded computer for standalone operation and wireless scanning: Instead of controlling it from your laptop via USB, you can scan wirelessly from any web browser.

Luxe DIY - How Did You Make This? Tutorial: The ModelBuilder Library For Processing & 3d Printing. Fabricating.com - Custom Parts. Custom made in the U.S.A. Craftzine.com: CRAFT: Dedicated to the renaissance in the world of crafts. Bolt. MAKEDO - Home. Hack N Mod - Amazingly Cool Hacks, Mods, and DIY Projects. The Shed Magazine. Power Laces- the Auto lacing shoe. The Online Magazine of Modern Machine Shop : Modern Machine Shop. Introducing Tabby: an industrializable, production ready, versatile, universal chassis. An Online Opensource Robot and Hardware Shop.

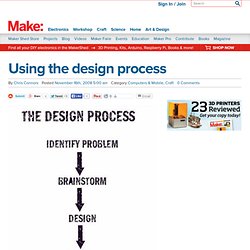

Maker’s Row - Factory Sourcing Made Easy. Using the design process. In engineering, programming, web design and most other creative work, many people consciously use The Design Process.

The PBS show Design Squad provides some great examples of how people can work with this system. There are also plenty of resources for working with students and other learners on their site. The Android G1 is pretty much ready for the public to use, but it is still not done. One of the reasons I wanted the G1 was to follow the process of developing a product from initial release. The phone and its systems work ok, well enough for product release. The innovation of the Android system and G1 phone is not limited to just employees, but explicitly involves the community of users and developers to make it a better system. Consider the the original ipod.

Steps Often, the is presented as a series of steps that you go through in developing an idea or product. Passionate about communities. It's time to write history with CMNTY Story.

Revolutionize the way you see your community. CMNTY Platform 2.4 The most advanced community platform available. Video introduction to CMNTY. Meet the products and the team behind it. Build Mobile Communities Use our native App for iOS and Android devices. Introducing CMNTY Key. Analyze activity with CMNTY Vision. Solid freeform fabrication: DIY, on the cheap, and made of pure sugar. In February we gave a sneak preview of our project to construct a home-built three dimensional fabricator.

Our design goals were (1) a low cost design leveraging recycled components (2) large printable volume emphasized over high resolution, and (3) ability to use low-cost printing media including granulated sugar. We are extremely pleased to be able to report that it has been a success: Our three dimensional fabricator is now fully operational and we have used it to print several large, low-resolution, objects out of pure sugar. The general idea of our build process– that of stacking solid two-dimensional printed layers– is actually common to most solid freeform fabrication methods.

Our machine employs what we believe is a fairly novel low-cost technology to accomplish this: selective hot air sintering and melting (SHASAM). A new open source hardware project every month. DIY122 – Make a LED Christmas Tree! In this special Christmas edition of Zedomax DIY122, we will show you how to make the geekiest Christmas Tree in the world using LEDs, bathroom pipes, and an embedded cubloc module.

Check out Pictures of the finished Christmas Tree Click here for complete HOWTO or Check out our Wiki for printable version. Sniffle Co. — Home. High-Low Tech. Magic ^ new media. Maker Shed, brought to you by the staff of MAKE and Maker Faire. Playclicks - Moldes y resina. Publicado el Viernes, 13 agosto 2010 por Yoyei Moldes y resina ¿Soñaste alguna vez con crear tus propias piezas?

Todos los aficionados se han preguntado alguna vez por qué no existe tal pieza o esa otra. Por qué Playmobil no crea otras series o esos muñecos que tanto nos gustan. Hasta ahora nos habíamos conformado con cambiar los accesorios de nuestras figuras. En estos tutoriales veremos que no hay nada imposible y que el límite nos lo pone nuestra imaginación. ADVERTENCIA: Estos manuales únicamente tienen como finalidad el crear piezas originales respetando las de patente de Playmobil.

Iniciación a los moldes. Custom Converter of High Performance Tapes, Films, Fabrics & Silicon. Is America's 1st Nationwide Open-Access Public Workshop. DESIGN SQUAD NATION . Home. Come play again later!

Come play again tomorrow! Become a Maker - DIY. ReadyMade. Cool Copper Projects Warm metallic hues are easy to love but often pricey.

HyperQuake Poster Series - #4. Do It Yourself streetview. List of Hacker Spaces. Fab.cba.mit.edu/about/labs/ DIY M134 Minigun Tutorials. Tutorials How to make airsoft Minigun?

Check this out! La plataforma para los jóvenes diseñadores españoles. Fab Central. Start [Fabout. Fabout is an open website for sharing designs for laser cutting.

Anyone can upload and edit vector graphics saved in uncompressed svg format. The vector files should adhere to common design guidelines. 100kGarages - Where projects are made by digital fabricators (fabbers) working with 2-D or 3-D digital fabrication tools. Home. 50 Digital Wood Joints. WikiHouse / Open Source Construction Set. How to package products attractively & on a budget. Here are a few cool examples from some Ponoko users: Jen Murse shows one lovely way to package jewelry. Chris Jackson makes excellent use of the so-called ‘waste’ materials [by using the whole sheet of Ponoko supplied material as the packaging for the clock face and the various clock parts - check out the 4th image].

Imagine what else you can do – like engrave your logo or assembly instructions, etc. Here’s another example of clever use of the ‘waste’ material (see 4th photo of Bza’s Soundwave Necklace) – he uses it to package the necklace pieces and has cut arrows to show the direction to thread these sound bite pieces onto a chain. Also Jason Wright-St.Clair shows us a very simple, very effective use of printed card. Packaging design. Builders/Metalab/AoI CSG Evaluator. CSG Evaluator - A useful plugin for AoI for doing multiple boolean operations Note: This software has been superseded by OpenSCAD - Overview of Ponoko's current educational material : Ponoko Community Hub. CerebralMeltdown.com - Classes, Coworking & Culture - Brooklyn, NY - 3rd Ward. Inventables: Find new materials. Technologywillsaveus - Welcome. Modkit. Smooth-On, Inc. - Mold Making & Casting Materials Rubber, Plastic, Lifecasting, and More. Art Supplies at Utrecht: Buy 13K Affordable Items in 400 Areas Online: paint.

Baker Creek Heirloom Seeds - 1400 heirloom garden seeds! TechShop is America's 1st Nationwide Open-Access Public Workshop. Gear Up! Top 10 Places to Find DIY Supplies. Shop Small Hobby Tools & Miniature Tools from Micro Mark. Welcome to Modernist Pantry - Magical Ingredients for the Modern Cook. Harbor Freight Tools – Quality Tools at Discount Prices Since 1977. Bombing Science: Graffiti Pictures & Graffiti Supplies. AmazonSupply.com: The Store for Business & Industry. 21st Century Crafts. Invent Your Own Anything. How-To: Make your own gears. We asked Dustyn Roberts, who teaches a course at NYU’s Interactive Telecommunications Program (ITP), called Mechanisms and Things That Move, to contribute something on fabricating your own gears for our Physical Science and Mechanics theme.

Dustyn has written a book, called Making Things Move. It’ll be out in the fall and we’ll have more about it, and likely a giveaway, then. How to make snug joints in Acrylic. The importance of radii We’ve written about using ‘nodes’ with 3D objects made from wood before, but suggested it may not work for acrylic because it is more brittle and less forgiving. However, after working with Drownspire to develop their Vambit toy into a product we could give away at Makerfaire, I discovered that you can successfully use nodes when making with acrylic. There are, however, some tricks to it. Firstly the nodes need to be a bit smaller <0.15mm/0.006″ on each side. This means it wont cover the same range as in wood but still a good option. Second, how you treat the end of the slot is the key. Add Colour to Your Laser Cut Detail. Paint filling and masking laser engraved parts. Painting in engraved detail gives your design an additional unique factor and makes less likely to scream “I’m laser cut!”

In the old days of hand cutting materials, you would have to sit there for hours, carefully applying masking tape of fluid in strategic areas to ensure a crisp paint edge. Like trying to paint straight stripes on a wall, only on much smaller scale. Fortunately, should you choose to try paint filling your laser cut engraving, your can mask required areas with laser cut precision. The acrylics are cut with protective paper on, and all engraved areas are ready to be painted. Transfer tape over white acrylic, over bamboo ply. How much material does the laser burn away? In 2008 I sought to try and quantify the kerf of our laser cutter, or how much material the laser cutter burns away when cutting specific materials. A guide to laser cut line optimisation : Ponoko Community Hub. Acrylic Glass Folding Heater. 16 October 2010 Author: Giorgos Lazaridis Acrylic Glass Folding Heater. DXF Projects & Patterns for CNC lasers Routers Scrollsaws. Free Dxf Art Downloads.