Waupaca Foundry culture is built on generations of excellence, industrial leadership and innovation. When customers expect your castings to perform in extreme conditions, you take exceptional pride in knowing your work is strong, dependable and high quality.

At Waupaca Foundry, generations of foundry excellence, industrial leadership, team innovation, and a heritage of taking care of our employees goes to work every day. We commit ourselves to create the best in class iron castings from a strong and stable company so our customers can depend on consistent castings. This wouldn’t be possible without a workforce made up of men and women who point to finished products with pride and say “we made those brake rotors.” We’re the largest iron castings producer in the world, but we also care that we have created a corporate culture where company picnics and 25-year work anniversaries are just as important.

Compacted Graphite Iron (CGI) K 4.1-4.2. Definition CGI is a material that can meet both the increasing demands for strength and weight reduction and still retain reasonable machinability.

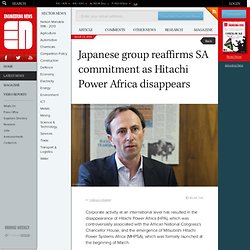

Japanese group reaffirms SA commitment as Hitachi Power Africa disappears. By: Terence Creamer Corporate activity at an international level has resulted in the disappearance of Hitachi Power Africa (HPA), which was controversially associated with the African National Congress’s Chancellor House, and the emergence of Mitsubishi Hitachi Power Systems Africa (MHPSA), which was formally launched at the beginning of March.

The 400-employee business assumes responsibility for the boiler contracts at Eskom’s Medupi and Kusile coal-fired power projects, which are also the largest and most complex currently being undertaken globally by the larger Mitsubishi Hitachi Power Systems joint venture, which is domiciled in Yokohama, Japan. The international merger of the thermal power units of Mitsubishi Heavy Industries (MHI) and Hitachi was announced in late 2012, but was formally launched in February, with MHI holding a 65% interest and Hitachi the 35% balance.

The joint venture's revenues were R124-billion last year. Edited by: Creamer Media Reporter. Web Exclusive Articles : Engine Technology International. Web Exclusive Article CGI breakthrough - An advanced third-generation compact graphite iron process, called Graphyte Flow, is transforming engine production For years, achieving the perfect diesel engine has been discussed – the one that delivers more power despite smaller dimensions and lower weight, that consumes less fuel and emits fewer greenhouse gases.

It has been said that using compacted graphite iron (CGI) will enhance the diesel engine’s attraction. So when will the time finally be right for using CGI technology to produce that cleaner and leaner diesel? The answer is, now. There is no filter or catalyst you can put on an engine to lower CO2 emissions, yet more demanding emission laws are coming into effect. Very soon, merely switching from gasoline fuel to diesel fuel will no longer be enough to reduce CO2 and other hazardous emissions. Soaring oil prices are here to stay, indefinitely.

Bühler AG: The Future of Light Metal Die Casting Foundries. Estimated worldwide production of automobiles (Source: PwC) as compared to forecast use of materials (Source: McKinsey, Advanced Industries 2012) Options for application and possible savings in weight when aluminum die cast structural components are used for the body structure of cars (Source: Bühler, Annual Report 2010) Example of typical use of the lost core technology: Closed deck motor block to increase the structural strength of highly charged diesel engines (Source: Volkswagen AG), on the right: salt core insert.

Tools such as Bühler’s «Event Analyzer» support foundries in their strategic optimization of the OEE (Overall Equipment Efficiency). Die casting machine are analyzed, statistically evaluated and made available to the user as well-founded analyses. MATERIALS HANDBOOK. SinterCast Introduces New CGI Process Control Package. SinterCast introduced a suite of new technologies it calls the third generation of its process control for compacted graphite iron (CGI) production.

System 3000 includes updated internal hardware components, a new operating system, new process control software, and extended measurement capability of core thermal analysis sampling technology. The first commercial license for System 3000 has been reached with China’s FAW Foundry Co. Ltd. It will install the research-scale version of the new package, SinterCast Mini-System 3000, at its R&D center in Changchun, China, in support of product development across the manufacturing group. FAW Foundry is an operating subsidiary of the China FAW Group Corp. The FAW Foundry Co. SinterCast also reported that the Cifunsa, the Mexican automotive foundry, upgraded its SinterCast System 2000 to System 3000 as a result of “intensified product development activity and anticipated increases in the overall market demand for CGI engine castings.”

Materials Science and Engineering. Yahoo - ABB Automation and SinterCast to Develop High Volume Solutions for the Production of Compacted Graphite Iron. Superfine graphite gray cast iron: high ultimate tensile strength combined with low hardness. Nowadays there are many alloys in the market that can satisfy the required physical and mechanical properties for a given application.

Gray Iron (GI) is still among the cheapest of ferrous materials available for engineers. Its high fluidity and ability to be cast into complex shapes together with the excellent machining qualities, damping capacity against vibrations, wear and fatigue resistances, thermal conductivity, and the possibility to use it in as-cast conditions are the main reasons why this alloy is traditionally chosen in many industrial applications, as cylinder blocks and heads, gears, flywheels, brake discs and drums, clutch plates, machine bases and beds, pipe fittings, flanges, etc.The possibility to improve the mechanical properties of GI is of great interest, as when high UTS (Ultimate Tensile Strength) is needed, designers prefer Compact Graphite Iron (CGI) or even ductile Iron (DI), which are higher in price. Www2.sintercast.com/file/documents/pdf/sintercast-testpdf-1.pdf.

SinterCast Introduces New CGI Process Control Package. Monitoring Innoculation. Graphite Innoculation - Flake - Spheroids - Vermiculite. Micrograph CGI iron showing graphite structure (Vermiculite)