Igus® Energy Chains®, polymer bearings, flexible cable & linear slides. NC Simul. Is a virtual CNC machine builder that simulates actual G code.

It does both machine and solid cut part simulation. NC Simul is faster, cheaper and better than CG Tech Vericut and it's a software product that is brilliantly designed and is a pleasure to use. Many CADCAM users are use to having to deal with saving, exporting, importing and managing .STL files when they do verification in a product like Mastercam. Not only is this a major time waster and a huge hassle but you aren't given the proper tools to get the job done quickly and efficiently. In the descriptions and screen shots I've created below you will see that NC Simul has an entire user interface for handling verification and for properly setting up part and machine verification.

NC Simul is capable of doing multiple machine process simulation at once. NC Simul Works Using A 3 Step Process:

Torque Tools - Rahsol Torque Tools, 'Estic' Electric Handheld Nutrunner - 'Handy2000', 'Tohnichi' Torque Tools and 'Britool' Torque Tools Supplier & Distributor from Pune, India. Maximum torque at minimum dimensions and minimum weight: These advantages are particularly valued by the demanding user of Losomat in everyday work It has been possible to save yet more unnecessary weight on the main components of the new power gear At the same time, the bearing of the moving parts has been improved tremendously, which leads to a clear extension in the life of the whole screwdriver equipped with the control electronics designed for rough permanent use, this series is again a true Losomat.

Patented torque and control electronics ensure trouble-free working with precise torques, while being safe from accidents Continuously turning through to the maximum torque and without any impact work, Losomat high torque wrenches are quiet and reliable An infinitely adjustable torque offers the desired level of comfort. Test certificate provides traceability in line with DIN EN ISO 9001:2000 Optional accessories, for example: The advantages of Losomat high torque electric wrenches: Torque Screwdriver List - Torqueleader.

Torque Screwdriver Applying Tools Torque Applying Tools are used to apply a set torque to a fastener; the tool will slip, break or click when the torque is reached to alert the operator.

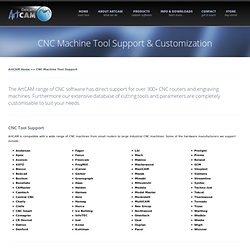

Many of Torqueleader's robust Torque Screwdrivers come in a variety of models, please see the Torqueleader range of Torque Screwdrivers below. Redefined TLS Preset Torque Screwdrivers Redefined TLS Preset Torque Screwdrivers Mechanism: NA Application: Preset and Calibrated We have redefined our range of Preset Torque Screwdrivers with 21st Century ergonomic design which improves operator comfort while retaining the quality, accuracy and durability that our reputation has been built on. CNC Machine Tool Support And Cusomization In ArtCAM. ArtCAM Home >> CNC Machine Tool Support CNC Tool Support ArtCAM is compatible with a wide range of CNC machines from small routers to large industrial CNC machines.

Some of the hardware manufacturers we support include: AndersenApexAxxiomAXYZBiesseBobcadBostomBusellatoCAMasterCamtechCentral CNCCharlyCielleCNC SmartComagravCR OnsrudDatronDenford FagorFanucFlexicamFrogMilliCarverGerberGravographHaasHeidenHermesHolzHomagHurcoIce BulldogInfoTECIselKomoKuhlman LSIMachMakinoMasterwoodMaxiCAMMazakMimakiMitsubishiModelaModel MasterMorbidelliMultiCAMNeo GroupNorthwoodOmnitechOsaiOuplanPacer ProlightPromaRolandSCMShopbotSiemensStreamlineSyntecTechno-IselTekcelThermwoodTornadoTryaxWarthogWedkinWeekeWigitWissner I can't see my hardware on this list... ArtCAM can also export toolpaths in G-Code, which is widely regarded as the industry standard format and compatible with the vast majority of CNC machines.

Delcam can also produce custom post-processors on request for a small fee. Automation Software. SVP Laser - Technologies Pvt. Ltd. CNC G-Code Programming Tutorial, Course, Examples, and Programs. Looking to learn CNC G-Code? Need a quick and easy G-Code Tutorial or G-Code Course? Want some easy G-Code Training? Maybe you just want to learn more about a specific G-Code related topic or see particular G-Code examples.

If so, you're in the right place with the CNCCookbook CNC G-Code Course. It's free, it's easy, and it's chock full of good information. Stepper Motors. A stepper motor is a brushless, synchronous electric motor that converts digital pulses into mechanical shaft rotation.

Every revolution of the stepper motor is divided into a discrete number of steps, in many cases 200 steps, and the motor must be sent a separate pulse for each step. The stepper motor can only take one step at a time and each step is the same size. Since each pulse causes the motor to rotate a precise angle, typically 1.8°, the motor's position can be controlled without any feedback mechanism. As the digital pulses increase in frequency, the step movement changes into continuous rotation, with the speed of rotation directly proportional to the frequency of the pulses.

Step motors are used every day in both industrial and commercial applications because of their low cost, high reliability, high torque at low speeds and a simple, rugged construction that operates in almost any environment. The rotation angle of the motor is proportional to the input pulse. DevFus, devWing, devFoam Prices and purchasing. Newfangled Solutions » CNC Software Home of Mach3. Software and Hardware Index.

CNCzone.com-CNC Machines, Cam/Cad ,Classifieds, Metalworking,Woodworking. Teds Woodworking® - 16,000 Woodworking Plans & Projects With Videos - Custom Woodworking Carpentry - Wood Plans.