Machining. GRBL. Grbl is software for controlling the motion of machines that make things.

If the maker movement was an industry, Grbl would be the industry standard. Most MakerBots and open source 3D printers have Grbl in their hearts. It has been adapted for use in hundreds of projects including laser cutters, automatic hand writers, hole drillers, graffiti painters and oddball drawing machines. Due to its performance, simplicity and frugal hardware requirements Grbl has grown into a little open source phenomenon. When we ordered our first computer controlled mill in 2007 we were stumped as to how we would control it. Choosing a controller We decided on the Arduino for several reasons. Yet it is a terrifyingly puny machine in the face of this task. What Grbl has to do in 2kb: Parse G-Code, a cryptic computer language hailing from the 50s used to describe the idealised actions of milling machines.

3100.pdf. G Codes. G81 (X- Y- Z-) or (U- V- W-) R- L- The G81 cycle is intended for drilling.

The cycle functions as follows: LINUX ENGRAVING. These instructions are designed for the camm2/camm3 but can easily be used for the newer units and also the vinyl cutters.

Old Way #1 Last Update Apr/08/09 Skip this section if you want to continue with the early solutions. Forums. Guidance and systems - SKF.com/Products/Mechatronics/Linear motion. S1-M2: Slide Mechanism and Concept. Pipe CNC Step 1: Linear Slide Mechanism and Concept November 22, 2007 Happy thanksgiving for those who live in the United States.

This is my first post in the Research and Development section of this website. You are probably wondering why I am adding the pipe CNC machine in such an illusive section. I want visitors of this website to know that this machine is a work in progress and all of the bugs and concepts are not fully known yet. Anyway, this enables me to share some of the ideas that run through my head. I am starting with the first video of the pipe CNC. Generally, the concept behind the slide mechanism is similar to the previous machine made of MDF and aluminum angles.

Lead Screws: Starts, TPI, Threads and Linear Motion for CNC Machines. Single Starts, 2 Starts, 5 Starts, TPI, Lead, HUH?!?

I think it's about time to talk about lead screws. So, what is this lead screw that is always mentioned throughout this website. Lead screws also have all of these terminologies and esoteric language that I will demystify. Maybe you will also start to understand the math behind the linear motion and how different lead screws will provide various linear motion characteristics. Cheap optical encoders, idea for DIY. Print on glossy paper did not work either..

BUT - printout on overhead projector foil, placed over shiny aluminium plate (as a background reflector) did work !!! So, it seems I have a workable solution.... I just have to do a proper design now. For vertical axis of my dobson it will be a round circular encoder pattern at the lower side of the drive wheel (like CD player, so it does not collect dust on the pattern), for horizontal axis it will be either a tape placed on the edge of the hor wheel, or again circular pattern (~120° sector only) at the inner side of the wheel, I am not sure yet what is better. Buy Power Transmission Components and other Mechanical Components parts. DC Motors parts with free next day delivery. Homemade CNC Router The Builder's Guide (FREE!) This guide is still under construction!

Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Homemade CNC routers can cut and carve almost anything. Browse for Products. Solutions Cubed Quadrature Encoder Kit. Home-Brew Shaft Encoders. Home-Brew Shaft Encodersfor thePittman GM8712 Gearhead Motor by David P.

Anderson Pittman GM8712-31 19.1 V. DC Gearhead Some nice small DC gearhead motors recently appeared on the electronic surplus market, suitable for jack-rabbit size hobby robots of 5 or 10 pounds. Rotary Encoder - 200 P/R (Quadrature) Playground - RotaryEncoders. ALPS STEC12E07 Encoder A rotary or "shaft" encoder is an angular measuring device.

It is used to precisely measure rotation of motors or to create wheel controllers (knobs) that can turn infinitely (with no end stop like a potentiometer has). Some of them are also equipped with a pushbutton when you press on the axis (like the ones used for navigation on many music controllers). They come in all kinds of resolutions, from maybe 16 to at least 1024 steps per revolution, and cost from 2 to maybe 200 EUR.

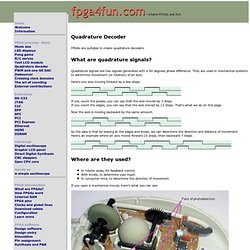

I've written a little sketch to read a rotary controller and send its readout via RS232. It simply updates a counter (encoder0Pos) every time the encoder turns by one step, and sends it via serial to the PC. This works fine with an ALPS STEC12E08 encoder which has 24 steps per turn. CNC. Search Results for “LS7266R1” Quadrature Encoder too Fast for Arduino (with Solution) » Dr. Rainer Hessmer. Motionco_Pulleys & Belts_3M HTD Timing Belts_Buy Online from Stock. Quadrature Decoder. Quadrature Decoder FPGAs are suitable to create quadrature decoders.

What are quadrature signals? Quadrature signals are two signals generated with a 90 degrees phase difference. They are used in mechanical systems to determine movement (or rotation) of an axis. Here's one axis moving forward by a few steps. If you count the pulses, you can say that the axis moved by 3 steps. Now the axis is moving backward by the same amount. So the idea is that by looking at the edges and levels, we can determine the direction and distance of movement.