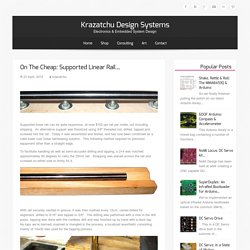

All-in-One 3D Printing and Slicing Software. Linear Bearing For Square Tube. Krazatchu Design Systems » On the Cheap: Supported Linear Rail… Supported linear rail can be quite expensive, at over $100 per rail per meter, not including shipping.

An alternative support was theorized using 3/8″ threaded rod, drilled, tapped and screwed into the rail. Today it was assembled and tested, and has now been confirmed as a valid lower cost linear rail/bearing solution. This following method required no precision equipment other than a straight edge. To facilitate handling as well as semi-accurate drilling and tapping, a 2×4 was notched approximately 90 degrees to carry the 25mm rail. Strapping was placed across the rail and screwed on either side to firmly fix it. With rail securely nestled in groove, it was then marked every 12cm, center-drilled for alignment, drilled to 5/16″ and tapped to 3/8″. After blind tapping, the 3/8″ threaded rod was cut to 14cm lengths and the cut ends were sanded to remove burs. With the rails assembled, the focus then shifted to the body of the Y-axis. Chinese Linear Rail Review. 3D printing guides: Radial and linear ball bearings! Linear Actuator Design.

$12 DIY Camera Track Slider. Making linear glides from drawer slides. CNC v0.6 build with simple tools and motors from optical drives or old printers. Rotary encoder or: How to build a digital servo using an Arduino and photo sensors. Lasersaur Manual. Index -- Laser cutters are systems for applying electromagnetic radiation to a work piece.

When done like a boss this will cause the material to disintegrate in the area of application. The challenge is doing this in a controlled manner and gaining full control of the energy density at any point in time. So, apart from safety, energy density over dt is our major concern here. To accomplish this control the Lasersaur uses a combination of robotic actuators and sensors, laser resonator, optical beam delivery, and control software. Lasersaur Manual. PCB Laserprinter. Otherworldy CAD Software Hails From A Parallel Universe. The world of free 3D-modeling software tends to be grim when compared to the expensive professional packages.

Furthermore, 3D CAD modeling software suggestions seem to throw an uproar when new users seek open-source or inexpensive alternatives. Taking a step apart from the rest, [Matt] has developed his own open-source CAD package with a spin that inverts the typical way we do CAD. Antimony is a fresh perspective on 3D modeling. In contrast to Blender’s “free-form sculpting” and Solidworks’ sequential extrudes and cuts, Antimony invites you to break down your model into a network of both primitive geometry and operations that interact with that geometry.

Functionally, Antimony represents objects as a graphical collection of nodes that encode both primitives and operations. Current versions of the software are available for both Mac and Linux, and the entire project is open-source and available on the Githubs. Parametric 3d CAD. Product Tour. Onshape Part Studios You can create and edit component geometry in Onshape Part Studios.

The modeling workflows are very similar to traditional CAD. However, there are new capabilities: Part Studios allow you to build multiple parts together. Parts can share sketches or features and can be used to shape each other using boolean operations.Version control is built into Onshape. "As a SolidWorks user, I was immediately comfortable with the layout and tools provided. Mini printable lathe V2. Latheplans. Millplans. Detailed Plans to convert a Sieg built Mini-Mill to CNC The plans are for converting the SIEG company's X2 Mini-Mill to CNC Sieg built Mini-Mills are sold by the following tool distributors: Harbor Freight model #44991 Grizzly Tool model #G8689 Homier model #3947 Micro Mark model #82573.

DAK Engineering - Relay Control. The question of how to connect and control a relay from the parallel port came up recently from a user of TurboCNC via email.

Here's how you can do it, even if you don't know a lot about electronics! You should be able to solder and recognize basic electronic components for this project. Baileigh Industrial. *shown with optional torch The PT-22 plasma table is not your normal 2 x 2 plasma cutting table.

The PT-22 offers many features not found on the competition at a great price. First off, the PT-22 comes fully assembled, no need to spend hours building hoping to have the alignment correct. A water bath is also part of the package, not an upgrade. Another nice feature of the PT-22 is that is comes with the material cross supports pre cut. Operation of the table itself only requires 110 volt power so it will work at almost any fabrication site throughout North America. The PT-22 plasma table is perfect for anyone getting into plasma cutting.

Building Inexpensive CNC Machines, Automatic Computer Controlled Robotic Motion Control PCB Circuit Board Drilling Drill Machine, Cheap, Easy to Make, using Surplus or Salvage Salvaged Stepper Stepping Motor Motors from old Dot Matrix or Daisywheel Printe. PLEASE, help support my efforts by checking out some of my own extra-special links: Gootee Curve Tracer's Homepage (also: DIY Kits)

CNC stuff. Xylotex.com. Traffic and Rank Indexed Pages Backlinks Load Time Page Loading Time: Seconds Search Traffic Related sites Latest Indexed Links.

Downloads - replicatorg - ReplicatorG is a GCode controller for RepRap compatible machines. 3rd Party Router Kits & Plans. Plans & Kits Modular CNC 3-Axis machine.

Build your router the way you want it at your own pace! LINKS page. Links Page Software Hardware Newgroups Plans Routers CNC/CAM software Links: TurboCNC Master5 (Win98) / Mach2 (Win 2000/XP) Deskam EMC (Linux) (requires cable mod) MaxNC Quickstep (requires cable mod) CNC ZEUS "Professional features, Hobbyist price" ArtSoft USA - Home of Mach3 and LazyCam. Taig Tools - Desktop Milling Machines and Lathes. The Sherline Lathe, Milling Machine and Precision Miniature Machining Page. Xylotex. LinuxCNC.org. Machines That Make. Machines That Make ------------------------------------- Jonathan Ward jdward (at) mit (dot) edu ------------------------------------- DIY PCB Milling Machine ------------------------------------- about: I'm developing a low cost milling machine to make printed circuit boards.

The structure for this machine was milled out of a 2' x 4' x .5" piece of plywood on a shopbot. Jonathan Ward - MIT - Machines That Make. Cartesian Motion Platform.