3D Printer. Fabbaloo Blog - Fabbaloo - Daily News on 3D Printing. 3d printing event. Microvision SHOWWX Laser Pico Projector: Amazon.co.uk: Computers. Journal of Chemical Education Online. Three-Dimensional Printing Using a Photoinitiated Polymer - Journal of Chemical Education (ACS Publications and Division of Chemical Education) The Center for Nanoscale Chemical-Electrical-Mechanical Manufacturing Systems (NanoCEMMS), University of Illinois, Urbana, Illinois 61801 Rantoul Township High School, 200 South Sheldon Street, Rantoul, Illinois 61866 J.

Chem. Educ., 2010, 87 (5), pp 512–514 DOI: 10.1021/ed800170t Publication Date (Web): April 13, 2010 Copyright © 2010 The American Chemical Society and Division of Chemical Education, Inc. Section: Abstract. Amazing Mindstorms 3D printer. Printing 2 bottles by UP! 3D Printer(www.PP3DP.com) UV-CAST™ Keypad Coatings for Electronic Devices. DYMAX UV-CAST™ light-curable coatings are designed to be molded onto plastic films and act as an outer layer of interfaces, including keypads. UV-CAST™ light-curing keypad coatings offer design flexibility while performing to stringent interface requirements including most common chemical resistance, impact, abrasion, and pencil-hardness specifications.

The UV-CAST™ molding process enables instant fabrication of various contours, shapes, and textures. Set-up costs are minimal compared to similar performing keypads that require injection molds. Eliminates high costs of injection molding, tooling, and energy use. Sthigpen.freeshell.org/si-links.html#3dp. Patent Searching Database. 3D Printing. </p><p><h2>ENABLE JAVASCRIPT<br />TO PLAY MOVIES<br />OF EACH STEP</h2> Original procedure developed by Nicholas Fang and adapted by Joseph Muskin, Matthew Ragusa, Kungway Chang, and Ian McInerny from the Center for Nanoscale Chemical-Electrical-Mechanical Manufacturing Systems, University of Illinois, Urbana-Champaign.

See "Three-Dimensional Printing Using a Photoinitiated Polymer," J. Chem. Educ., 2010, 87 (5), pp 512–514. In this lithography experiment light creates free radicals from phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide which induce polymerization of 1,6-hexanediol diacrylate. Clicking a thumbnail on this web page ( shows a movie of that step. This experiment uses a computer with powerpoint and connected to a video projector, a magnifying glass, mirror, and a platform elevator. Fill the beaker with monomer solution to just above the level of the platform Red light is used for alignment but does not cause polymerization.

3d Printing - the Nano-CEMMS Center. This lab uses a process based on a research project headed by Professor Nicholas Fang and developed at the Nano-CEMMS center at the University of Illinois.

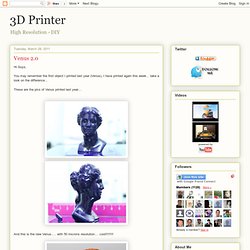

Dr. Fang's research group is using a UV sensitive monomer to do a form of three-dimensional printing called microstereo lithography. Using a video projector with a UV output, they are able to create incredibly thin polymer layers (on the order of 400 nm) and build objects layer by layer. This activity uses the same principle but at a much larger scale. Venus 2.0. Hi Guys, You may remember the first object I printed last year (Venus), I have printed again this week... take a look on the difference...

These are the pics of Venus printed last year.... And this is the new Venus..... with 50 microns resolution.... cool!!!!!!!! Homemade high resolution DLP 3D printer. This link came in the mailbag from one Junior Veloso, of Singapore, who has produced this very impressive homemade photopolymer-based 3D printer.

Traditional stereolithography uses a scanning UV laser to cure the liquid resin, one layer at a time. A DLP printer is similar, but uses a micromirror-based video projector to expose each layer, as shown in the diagram. Junior’s version exposes each layer for four to eight seconds, resulting in print times on the order of several hours. The resin has to be opaque to prevent “shadowing” from light transmitted through the printing layer. What comes next?? Hi Guys, I have been receiving many questions around my plans for the 3D Printer and what are the next steps.

My plan is very simple, improve the project in a way that anyone could build one of this 3D Printer at home. Additionally I may bring some commercial kits or parts so you don't need to buy a CNC or any other expensive tool to build your own 3D printer. In my to do list to improve the project I have: 1) Improve material and reduce cost2) Improve software3) Improve a little bit the electronics ( this is almost done)4) Document everything (including videos) Homebrew Liquid Resin 3D Printer Gets Resolution Boost. We’ve previously posted about Junior Veloso’s liquid resin 3D printer, which uses a DLP projector beneath a bath of resin to cure an object into its appropriate shape.

Junior is reporting a huge gain in resolution from multiple improvements in the design. From our friends at Hack A Day: He’s keeping most of the juicy bits to himself but he did tell us that the improvement he achieved were due to multiple changes in the process. Meet the i.materialise team: Wim. My name is Wim Verstraeten.

Consider me a battle scarred veteran in the field of the online ordering of 3d printed models. I date back from the era where Materialise was the only firm to have an online 3D printing service with its NextDay service which was started in 1997. I’m talking about the time when only the happy few had a mobile phone and Amazon and eBay had existed for almost 4 years. Cathedrals. 3D printer prijs - overzicht goedkoopste printers. Menu 3Dprinter.nu.

BfB 3D 3000 - Wiki.