The Doctors of Tomorrow Will Be Supercomputers. Caterpillar Has Funded a Robot that will Revolutionize Home Building. WEF Shaping the Future of Construction Inspiring Innovators redefine the industry 2017. How automation and technology will change the buildings we live in. Our built environment and its entire value chain are in the wake of a severe transformation.

Artificial intelligence (AI), the Internet of Things, robotics and other technologies are not only responsible for the emergence of smart cities, automated processes and new business opportunities, but a change to the rules underpinning the real estate industry. The impact of technological disruption on this industry transcends the possible automation of construction or robotic substitution of real estate agents. Technological innovation will prolong our life expectancy, severely alter the job market and affect our ecosphere and social life. How will these broader consequences shape our built environment? Increasing longevity and our ageing society Preventive and technologically-enhanced reactionary healthcare will significantly increase the longevity of future societies. How automation and technology will change the buildings we live in. China Is Building Living, Breathing Buildings. In Brief Nanjing's vertical forest will consist of two buildings whose construction will incorporate 1,100 trees and over 2,500 shrubs and plants in the hopes of improving the city's air quality.If successful, this innovative solution could be replicated throughout China and other pollution-stricken nations, bringing a better quality of air to people worldwide.

China is looking toward more innovative — and in this case, breathtaking — solutions to its pollution problem. More than eight million people live in Nanjing, the second largest city in the East China region, so there’s hardly any room to plant new trees to combat the city’s pollution. As an alternative, Nanjing is building a vertical forest by constructing living, breathing buildings that can serve to absorb carbon dioxide and produce oxygen at the same time.

This vertical forrest is essentially two buildings whose construction will incorporate 1,100 trees and over 2,500 shrubs and plants. Adidas Unveils a Shoe That Can Be Dissolved in Your Sink. In Brief Sportswear giant Adidas has introduced a shoe made with 100 percent biodegradable materials.The shoes are another product of the company's forward thinking initiative to bring us the sportswear of the future.

Digital Sneakers Have Arrived. Spray-on clothing. ‘Smart clothes’ for personalized cooling and heating. Garment-based printable electrodes (credit: UC San Diego) Instead of heating or cooling your whole house, imagine a fabric that will keep your body at a comfortable temperature — regardless of how hot or cold it actually is.

That’s the goal of an engineering project called ATTACH (Adaptive Textiles Technology with Active Cooling and Heating) at the University of California, San Diego, funded with a $2.6M grant from the U.S. Department of Energy’s Advanced Research Projects Agency – Energy (ARPA-E). By regulating the temperature around an individual person, rather than a large room, the smart fabric could potentially cut the energy use of buildings and homes by at least 15 percent, said project leader Joseph Wang, distinguished professor of nanoengineering at UC San Diego.

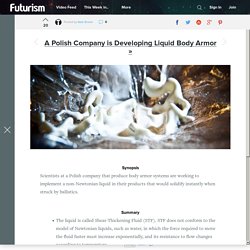

A Polish Company is Developing Liquid Body Armor - Futurism. Synopsis Scientists at a Polish company that produce body armor systems are working to implement a non-Newtonian liquid in their products that would solidify instantly when struck by ballistics.

Summary The liquid is called Shear-Thickening Fluid (STF). STF does not conform to the model of Newtonian liquids, such as water, in which the force required to move the fluid faster must increase exponentially, and its resistance to flow changes according to temperature. Instead STF hardens upon impact at any temperature, providing protection from penetration by high-speed projectiles and additionally dispersing energy over a larger area.According to the researchers, both liquids can find applications beyond body armor, such as in the production of professional sports inserts, and even entire outfits.

Mobile 3D Clay Printer: Whole Houses from Local Mud. In Brief Easy to disassemble and transport on demand, this 3D-printing solution uses natural materials to build completely stable homes from readily available resources Designed by WASP (World’s Advanced Saving Project) and deployed recently at a maker fair in Rome, the Delta device itself is lightweight and can be loaded onto a truck, moved then rebuilt in a matter of hours.Structurally, the system employs curved walls, arches and domes to create solid buildings that can withstand the test of time.

For its source material: dirt, clay and water are fed into the machine, leaving the results to dry naturally in the sun. Millennials Will Live In Cities Unlike Anything We've Ever Seen Before. A Chinese Company 3D. Human Vs. Robot: Bricklaying Robot Can Place 1,000 Bricks an Hour - Singularity HUB. Building houses of brick is almost as old as human civilization itself, and over the millennia, we’ve perfected the art.

The fastest bricklayers can mortar and place over 700 bricks an hour. Pretty fast. But a new robot can lay bricks even faster. Mark Pivac, inventor of the bricklaying robot, Hadrian, told PerthNow that his bot can place 1,000 bricks an hour, enough to erect the walls of a house in two days of round-the-clock work—a task that, on average, takes a human crew four to six weeks of hard labor. The robot works a little like a 3D printer, similarly taking its cues from a digital 3D model of the structure it’s building. Hadrian took ten years and A$7 million to develop. A Robot Called Hadrian Wants to Build You a House in Two Days. 3D Printer Builds Homes From Mud In Impoverished Areas.

Nearly one billion people around the globe are homeless or live in substandard housing.

In the era of 3D printing, some have addressed this crisis through quickly built concrete buildings. While this method would create a secure dwelling, delivering the raw materials and bulky printer increases the cost significantly, reducing its feasibility. The Italian 3D printing company WASP may have solved this problem by developing an easily-transportable machine that can quickly create dwellings out of mud and natural fibers—materials already available where the houses will be built. Making houses out of mud is not anything new. The 3D printer that can build a house in 24 hours. Getty The University of Southern California is testing a giant 3D printer that could be used to build a whole house in under 24 hours.

Professor Behrokh Khoshnevis has designed the giant robot that replaces construction workers with a nozzle on a gantry, this squirts out concrete and can quickly build a home according to a computer pattern. In China, 3D-printed mansions and apartment blocks are now a reality - Futurism. This Machine Will Give Billions Access to Potable Water. Ultra-cheap cleaning process converts sea water into drinkable water. Holographic Ads Are Now In Supermarkets. Synopsis This week, Mondelez -- the former snacks division of Kraft that manufactures brands such as Chips Ahoy, Trident and Cadbury -- unveiled the first-ever holographic display ads in a grocery store.

Summary. Cost of lab-grown burger patty drops from $325,000 to $11.36. Back in 2013, ‘test-tube’ hamburgers hit headlines across the Internet, and not just because scientists had managed to more-or-less replicate meat in the lab. It was a commendable feat, especially because it offered a potential solution to the increasingly unsustainable practice of cattle farming, but then we heard about the price tag. Who’s up for a $325K burger made from cultured muscle tissue cells? Cultured meat could spell the end of traditional cattle farming within just a few decades - Futurism. PlantLab: Urban Farms 40 Times More Productive than Open Fields - Futurism. Synopsis A Dutch firm on the cutting edge of indoor agriculture estimates that producing food for the entire world could take place in a space far smaller than the area occupied by Holland.

Summary PlantLab suggests a solution that involves using existing basements and purpose-built structures for our future food production. This means less energy, space, time and an estimated 10% of water relative conventional methods.Urban farming in controlled environments lets growers take full advantage of variables like custom lighting, using far-red LED lamps in this case that reduce moisture requirements for plants.