List of sensors. This is a list of sensors sorted by sensor type.

Acoustic, sound, vibration[edit] Automotive, transportation[edit] Chemical[edit] Electric current, electric potential, magnetic, radio[edit] Environment, weather, moisture, humidity[edit] Flow, fluid velocity[edit] Ionizing radiation, subatomic particles[edit] Learn Sensors: Ladyada Tutorial. This is a photo of an FSR, specifically the Interlink 402 model.

The 1/2" diameter round part is the sensitive bit The FSR is made of 2 layers seperated by a spacer. The more one presses, the more of those Active Element dots touch the semiconductor and that makes the resistance go down What is a Force Sensitive Resistor? FSRs are sensors that allow you to detect physical pressure, squeezing and weight.

FSR's are basically a resistor that changes its resistive value (in ohms Ω) depending on how much its pressed. However, for most touch-sensitive applications like "has this been squeezed or pushed and about how much" they're a good deal for the money! Some basic stats These stats are specifically for the Interlink 402, but nearly all FSRs will be similar. How to measure force/pressure with an FSR As we've said, the FSR's resistance changes as more pressure is applied. Testing your FSR Connecting to your FSR Because FSRs are basically resistors, they are non-polarized. Project examples. Capacitive sensing. In electrical engineering, capacitive sensing is a technology, based on capacitive coupling, that takes human body capacitance as input.

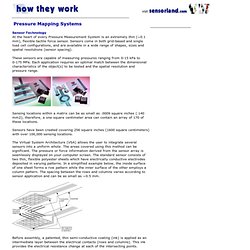

Capacitive sensors detect anything that is conductive or has a dielectric different from that of air. Design[edit] Capacitive sensors are constructed from many different media, such as copper, Indium tin oxide (ITO) and printed ink. How Pressure Sensors Work. Pressure Mapping Systems Sensor Technology At the heart of every Pressure Measurement System is an extremely thin (~0.1 mm), flexible tactile force sensor.

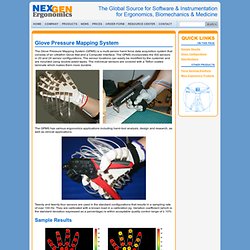

Sensors come in both grid-based and single load cell configurations, and are available in a wide range of shapes, sizes and spatial resolutions (sensor spacing). These sensors are capable of measuring pressures ranging from 0-15 kPa to 0-175 MPa. Each application requires an optimal match between the dimensional characteristics of the object(s) to be tested and the spatial resolution and pressure range. Sensing locations within a matrix can be as small as .0009 square inches (.140 mm2); therefore, a one square centimeter area can contain an array of 170 of these locations. Sensors have been created covering 256 square inches (1600 square centimeters) with over 100,000 sensing locations. The Virtual System Architecture (VSA) allows the user to integrate several sensors into a uniform whole. Application in Chemical Mechanical Polishing. Glove Pressure Mapping System. The Glove Pressure Mapping System (GPMS) is a multi-sensor hand force data acquisition system that consists of an Ultrathin Glove Mat and a Computer Interface.

The GPMS incorporates the ISS sensors in 20 and 24 sensor configurations. The sensor locations can easily be modified by the customer and are mounted using double-sided tapes. The individual sensors are covered with a Teflon coated laminate which makes them more durable. The GPMS has various ergonomics applications including hand-tool analysis, design and research, as well as clinical applications. Tactile Sensor Products. Innovative thin‐film pressure mapping sensors. E. Preston (Electrical) Ltd » Blog Archive » Honeywell Extends Its TruStability® Pressure Sensor Product Line with a Single Side Liquid Media Option. Allows One Sensor Port to Be Used with Condensing Humidity or Directly with Non-corrosive Liquid Media Honeywell introduced a single side liquid media option to its extensive line of TruStability® Pressure Sensors originally introduced in July 2009.

The new single side liquid media option allows customers to use one port of the sensor with condensing humidity or non-corrosive liquid media, such as de-ionized water, eliminating the complexity and expense of having to protect the sensor from this type of media. Honeywell has developed this option because of the many applications where condensing humidity conditions exist or where liquid media is the desired media to be measured. Until now, Honeywell’s TruStability® Pressure Sensors have been intended for use with non-corrosive, non-ionic working fluids such as air and dry gases. * Temperature compensated and calibrated, providing an extremely tight accuracy specification; Both series offer the option of analog or digital outputs. Home Page:

NanoEngineers Print and Test Chemical Sensors on Elastic Waistbands of Underwear. NanoEngineers Print and Test Chemical Sensors on Elastic Waistbands of Underwear June 17, 2010 By Daniel Kane Chemical sensors printed directly on elastic underwear waistbands retained their sensing abilities even after engineers stretched, folded and pulled at the chemical-sensing printable electrodes – sensors that could one day be incorporated into intelligent “hospital-on-a-chip” systems.

This work, funded by the U.S. Office of Naval Research, is led by professor Joseph Wang, from the Department of NanoEngineering at the University of California, San Diego Jacobs School of Engineering. The primary goal of the new peer-reviewed study, published in the journal Analyst, was to aggressively test the performance of electrodes printed directly on textiles, something the researchers say has not been done before.

A 2008 ONR grant announcement from UC San Diego introduced this project. “We just want the ones and zeros. “This is biocomputing in action,” said Wang. Pulse Sensor. Force Sensors.