A visit to a Bali. Coiling is a traditional way of making pottery that has a long history.

It has been used for many thousands of years, from Africa to Greece and from China to New Mexico. The method has been applied in a variety of ways and for pots of various sizes. Any older method than this probably came around when any of our forefathers tried to water proof a basket with mud and then sat the whole thing on fire by accident, or while trying to move a fire, by carrying it in a mud protected basket. Both should have resulted in the observation that mud could be hardened by fire. The basic technique starts by making a coil, or a clay string. From old Chinese Neolithic pottery it is obvious that the pots were very early in history placed on straw mats that could well have been turned while smoothening, which would have been the first step towards the eventual inventing of the potters wheel. Shift: La Morena. Long has concrete been regarded as a cold and industrial material.

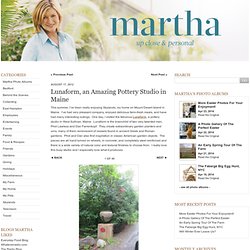

Shift, a young design firm based in Monterrey, believes its manual processes and properties, however, make it a modern, expressive and rich substance fit for many objects that have not yet been explored. Shift, La Morena La Morena is their first attempt to relocate this material as a highly aesthetic, modern and friendly component. La Morena is a small pot that combines two materials rarely seen together, wood and cement. The combination of both results in an honest and balanced artifact where concrete’s stony aesthetics are countered and warmed by wood’s organic looks. Self-Study Concrete Countertop Training : concrete countertop training, concrete countertop books, concrete counter top training, concrete counter top books : The Concrete Countertop Institute. Lunaform, an Amazing Pottery Studio in Maine. 1 The entrance to Lunaform is through a gate marked by a single giant urn on an iron stand.

Both are indicative of the work that the potters at Lunaform excel in. 2 In the woods stands a magnificent red jar. Each shape of jar and pot at Lunaform has a name. This one is XL Milano and is 66-inches tall. 3 I love the shape and size of this monumental pot, called Dozzina, standing 50.5-inches tall. 4 This footed planter is very reminiscent of the work of Frank LLoyd Wright and would look great at any one of his buildings. 5 Upon entering the pottery, we were greeted by this lovely French bulldog. Seamless operation: Sullivan company creates one-of-a-kind concrete forms — Hancock.

SULLIVAN, Maine — In a Japanese-inspired compound surrounded by forest, a team of craftsmen have developed a unique process to create enormous one-of-a-kind concrete forms.

The facility at Lunaform LLC is surrounded by and filled with pieces ranging from colossal, 1,500-pound planters down to what pass for small works — knee-high, 210-pound “Luna” urns, the company’s namesake piece. The company founded and operated by Phid Lawless and Dan Farrenkopf makes hand-turned, dry-packed concrete garden urns, planters, pots and more. And they’re the only ones in the game. “Right now, in North America, this process is unique to us,” Farrenkopf said during a recent tour of the Sullivan shop. Concrete Molds - Countertop, Sink, and Furniture Molds. Molds & Mold Rubbers Time: 3:45 ideo demonstration for creating forms and molds of unique designs for concrete countertops.

Nearly all concrete placed anywhere is molded in one way or another. A mold is really the same thing as concrete formwork-or shuttering if you're British. But it's usually only called a mold when it is smaller, more detailed-such as for a countertop or a sink or concrete furniture. Although some people refer to stamped concrete surfaces as being molded when referring to the pattern or texture, such as on patios and walkways. A popular feature of concrete countertops is an integral molded sink. Countertop makers mold these sinks either with their own custom-made molds or with purchased molds. Stiff Mixes versus Fluid Mixes - Tech Talk > Mix Design - Articles : Concrete Countertops, Institute, Concrete Connections, Raleigh, NC : The Concrete Countertop Institute.

There are several considerations to make when choosing a concrete countertop mix consistency.

Some factors include the appearance of the finished piece, the forming and casting methods, and the complexity of the mold geometry. Other factors that are not so obvious also drive the selection process. These can include the type of mixer that will be used, how the forms are assembled, the shrinkage tendency of the concrete and subsequent vulnerability or resistance to curling and hairline shrinkage cracks.

This article outlines the differences between two mix styles, stiff and fluid, in design, look and technique. There are two basic types of mix consistencies: stiff and fluid. How to Build and Install a Concrete Countertop. Remove the sides of the mold from the concrete first, being careful not to press against the concrete.

Cut the wire that was suspending the rebar or steel mesh as close to the surface of the concrete as possible. Precast Concrete Planters, Receptacles and Furnishings.