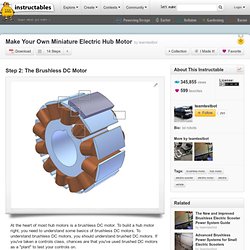

The Brushless DC Motor. At the heart of most hub motors is a brushless DC motor.

To build a hub motor right, you need to understand some basics of brushless DC motors. To understand brushless DC motors, you should understand brushed DC motors. If you've taken a controls class, chances are that you've used brushed DC motors as a "plant" to test your controls on. I've highlighted and bolded the juicy stuff that you'll need, but for the sake of continuity it's probably good to grunge through all of it anyway. Powercroco halbach. © Dr. Ralph Okon 07072006. What are iron free motors?

Quote: OK - everyone can have his own opinion about.

At that in books and articles these therms and questions are in rag-bag disorder even from professors. My opinions. Powercroco - kombinationstabelle und bewicklungsrechner. ThinGap Brushless and Ring Embedded Motors, Powerful & Lightweight DC Brushless Motors. Magnetic Levitation Train 1. [Main] [Project Deliverables ] [Progress Log] [Methods/Research ] [References/Links] Halbach Array The basis of the Inductrack method is the use of Halbach arrays.

The Halbach array is a special formation of magnets used to direct each individual magnet’s field to create a strong quasi-uni-pole magnetic field. The formation was invented by Klaus Halbach for the use of particle acceleration [2]. The standard formation using 90 degree angles is shown in figure 1. Iron loss seperation - trends in high-torque BLDC Motors. Motors & generators with MotorSolve High torque motors of the BLDC type are required to deliver high power, and are usually characterized by low operating speed and synchronous frequency, high number of poles and teeth, etc.

Given the power requirement, loss minimization is usually an important design criterion for such machines. Depending on the operating conditions, iron losses may be a significant fraction of the total loss and qualitative and quantitative knowledge of their variation with respect to design parameters (electrical and geometrical) could be quite useful to the machine designer. Even fractional improvements in minimizing losses can be useful, and energy savings at this level can only be predicted by accurate FEA based analysis. Brushless Slotless Powder Core Motor - Page 2. *the magnets are sitting next to each other, N-S-N-S-N-S and so on all way around the rotor* - thats I called "multilayer magnets", sorry I cant find better name for this very unprofessional thing in motor buildings.

English is not my mother tongue, its very hard for me. Mostly none understand what Im speaking When I do build high speed spindle (30krpm...50krpm) then I use SM powder materials for flux ring, for stator ... as well as for back iron, depends what kind motor. And ONLY segmented custom made magnets, correctly designed, not coated or coated wheres no copper - I agree with your standpoint about insignificant losses caused by rotor coatings - but only when low speeds! You motor is low speed and losses what come from flux returning material are also very small.

You planned to build this motor in one two year ... mh-mhh, very nice, after few months none remember this thread and you can carry out a new idea. DIY Inrunner. LRK Site. TECHNOLOGIEN UND GRENZEN VON HIGH TORQUE ANTRIEBEN - Institut für Elektrische Maschinen und Antriebe (TU-BRAUNSCHWEIG) {*style:<b><b> 05antriebstechnik-zimmer-boecker-schmidt-schulz.pdf (application/pdf-Objekt) STM32 - 32-bit ARM Cortex MCUs. REASONS FOR TURNING TO SLOTLESS MOTOR TECHNOLOGY.pdf (application/pdf-Objekt) Powercroco nutloser Aussenläufer. Wie erwartet hat der Motor quasi kein Rastmoment, woher auch. An einem normalen Jazz dreht er 10000RPM bei 10V. Leerlaufstrom im Ersten Versuch allerdings 1.6A, das ist richtig mies, vor allem im Vergleich zu den Berechnungen. Als erster Schritt wurde der Lüfter zugeklebt, um zu testen, was der Lüfter an Verlusten bringt. Daß man später ordentlich lüften muß, ist klar, aber es ist eben ein Unterschied, ob die Verluste rein als Wärme üder als Kühlung entstehen...

Zugeklebt war die Stromaufnahme bei 1.1A. Versuchsweise wurde der Motor dann von aussen per Glockenankermotor angetrieben, und die dafür notwendige Leistung angesehen. Offensichtlich schirmt der Kern das Alu-Rohr des Statorträgers doch recht gut ab, wie eigentlich auch die femm gezeigt hatte. Mit einem zusätzlichen Alu-Ring wie es der Ring unter dem Kern darstellt, war der Leistungsbedarf nochmal deutlch höher.

Die Verluste wurden also erst mal in Wirbelströmen vermutet. 7mm brushless inrunner motor. BIG STATOR LINE. Motor Calculations. Brushless Permanent Magnet Motor Design,2 Ed. Category: Technical Tag: Science/Engineering.

Outrunner vs Inrunner. Theres a nice little debate on the high performance forum: I know this debate's been going on for a while, but I thought I'd bring it to the attention of experts here who perhaps don't spend much time there.

In summery this argument is specifically about high kV outrunners replacing inrunners for pylon racers, EDF's and other high RPM direct drive applications Outrunners have a clear geometric advantage over inrunners for producing torque most efficiently. For that reason in low power/low RPM area outrunners replace geared inrunner systems. But when high RPM outrunners started coming out, it was possible to replace the jobs of inrunners running around 30,000 RPM with a much lighter outrunner producing the same power! Now the question is what are the performance limits of high RPM outrunners and would it be possible for them to replace inrunners in the super high performance arena--150+ mph f5d planes, jets, wings or whatever else is fast and direct drive.

Thanks!!